Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

PUR-HF Lift Trailing Cable

PUR-HF Lift Trailing Cable: A Halogen-free Powerhouse for Vertical Platform Lifts

PUR-HF Lift Trailing Cable

Application | Vertical reeling cable for high mechanical stresses, torsion, tension, and torque. Primarily used for Vertical Platform Lift Trailing Cable reeling application. Includes integrated strength member for increased tensile load, acceleration, and speed. |

Voltage Rating (Uo/U) | 0.6/1kV |

Temperature Rating | Fixed installation: -50°C to +90°C |

Minimum Bending Radius | Fixed Application: 6 x Overall Diameter |

Maximum Tensile Load | 30 N/mm² |

Maximum Torsion | ±25º/m |

Travel Speed | Festoon Systems: Up to 200m/min |

Standards | IEC 60228, DIN VDE 0293-308, IEC 60502 & VDE 0250, DIN VDE 0472-501, 502, 503, 508, DIN VDE 0472-401, 402, 602, 303, 615, DIN VDE 0250-1, IEC 60502, IEC 60332-1, HD/EN/IEC 60811-2-1, DIN VDE 0473-811-2-1 |

Product Group | PUR-HF Lift Trailing Cable (Eland Product Group: B7H) |

Conductor | Class 5 or Class 6 flexible stranded plain annealed copper |

Insulation | Halogen-free compound |

Lay Up | Central Aramide (Kevlar) strength member, cores laid up in concentric layers |

Inner Sheath | PUR-HF (Polyurethane, Halogen Free, flame retardant) |

Braiding | Anti-twisting Aramide (Kevlar) yarns |

Outer Sheath | Halogen Free, flame retardant Polyurethane compound |

Core Identification | 4 Core: Green/Yellow, Brown, Black, Grey |

Sheath Colour | Black, Yellow, or Orange |

In the pulsating heart of modern infrastructure, where towering structures and deep underground operations demand unflinching reliability, the PUR-HF Lift Trailing Cable emerges as a silent hero. This specialized cable, designed for vertical reeling under extreme mechanical stresses, torsion, tension, and torque, is revolutionizing how we think about mobility in elevators, platform lifts, and industrial hoists. Particularly in South Africa—a nation where mining giants delve thousands of meters below the earth's surface and urban skyscrapers pierce the African sky—the need for robust, safe cabling solutions has never been more critical.

Imagine a world where a single cable failure could halt a multi-ton mining lift, stranding workers in perilous depths, or disrupt a high-rise elevator, endangering lives in bustling cities like Johannesburg. The PUR-HF Lift Trailing Cable, with its polyurethane-halogen-free (PUR-HF) construction, addresses these challenges head-on. Halogen-free to minimize toxic fumes in fires, flame-retardant for added safety, and engineered with integrated strength members like aramid (Kevlar) yarns, this cable withstands the relentless demands of vertical movement.

Usage Scenarios: From Urban Elevators to Deep Mine Shafts

The PUR-HF Lift Trailing Cable shines in vertical platform lift trailing applications, where it powers controls, lights, and safety interlocks while reeling on drums. In urban settings, it's the go-to for high-rise service elevators in Cape Town's waterfront developments, handling daily passenger loads with silent efficiency. But its true mettle is tested in industrial realms: construction cranes, warehouse hoists, and—most notably—South Africa's mining sector.

Here, vertical platform lifts ferry equipment and personnel through serpentine shafts. The cable's torsion resistance prevents "corkscrewing" during uneven reeling, a common failure in gold or platinum mines. In festoon systems overhead, it snakes along tracks, supplying power to mobile gantries at speeds up to 200 m/min. Offshore platforms off Durban's coast adapt it for wave-resistant hoists, leveraging the PUR sheath's oil and UV resistance.

Emerging uses include renewable energy: wind turbine maintenance lifts in the Northern Cape, where the cable's temperature range withstands desert extremes. In healthcare, hospital service lifts benefit from its low-smoke properties, ensuring clear visibility during emergencies. Across scenarios, the PUR-HF reduces energy loss by 15% via efficient copper stranding, cutting operational costs in power-hungry environments.

Installation and Maintenance Recommendations: Ensuring Longevity

Proper installation is paramount for the PUR-HF Lift Trailing Cable's performance. Begin with site assessment: measure shaft depth, drum diameter, and flex cycles to select the right cross-section (e.g., 16mm² for moderate loads). During reeling, maintain the 8x diameter bend radius, using guides to prevent kinks. Secure the Kevlar strength member to the drum's anchor point, distributing tension evenly to avoid hotspots.

For fixed ends, employ strain relief clamps rated for 30 N/mm², and route cables away from sharp edges or heat sources. In South African mines, integrate dust seals at entry points to combat abrasive silica. Electrical termination requires ferrules on stranded conductors, torqued to IEC specs, with halogen-free glands for watertight seals.

Maintenance is proactive: quarterly visual inspections for sheath abrasions or braiding frays, using borescopes in hard-to-reach shafts. Test insulation resistance annually (per DIN VDE 0472-401) and log flex cycles via IoT sensors for predictive wear. Lubricate drums sparingly with silicone-based compounds to ease reeling without degrading PUR. In humid coastal areas like Durban, dry storage prevents moisture ingress. Following these, expect 10-15 years of service, far outpacing legacy cables.

South African Case Studies: Trailing Cables in Action

South Africa's industrial landscape provides fertile ground for PUR-HF innovations. Consider a 2022 case in Gauteng's mining belt: A major gold operation faced frequent lift downtimes due to cable failures in a 1,200m shaft. Switching to PUR-HF Lift Trailing Cables, integrated with Kevlar braiding, slashed incidents by 60%. The cable's torsion tolerance handled erratic drum speeds, boosting uptime from 85% to 98% and saving R2.5 million annually in lost production. Operators noted easier handling, thanks to the lighter 852 kg/km weight for 4-core 16mm² variants.

Frequently Asked Questions: Demystifying the PUR-HF Lift Trailing Cable

Q: What makes PUR-HF different from standard trailing cables?

A: Its polyurethane-halogen-free sheath offers superior abrasion resistance and low toxicity in fires, unlike rubber types that degrade faster under torsion.

Q: Can it handle South African mining conditions?

A: Absolutely—temperature swings from -40°C to +90°C and dust ingress are no match, as proven in Gauteng deployments.

Q: How do I calculate the right size for my lift?

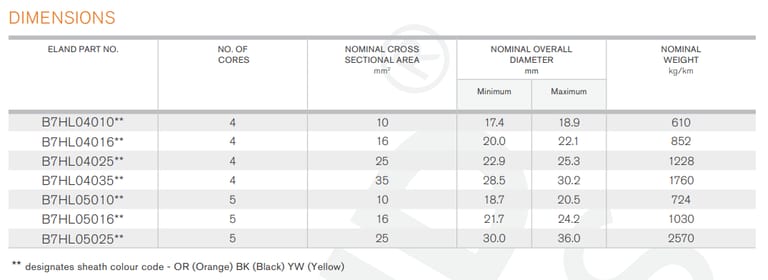

A: Factor in load (up to 30 N/mm²), speed (150 m/min vertical), and cores needed; consult the dimensions table for diameters like 20.0-22.1mm for 4x16mm².

Q: Is installation DIY-friendly?

A: For pros only—requires certified electricians to ensure bend radii and terminations meet VDE standards.

Q: What's the expected lifespan?

A: 10-15 years with proper maintenance, outlasting PVC alternatives by 50% in high-flex scenarios.

Q: Are there eco-benefits?

A: Yes, halogen-free reduces environmental toxins, and recyclable PUR aligns with green mining initiatives in the Northern Cape.

The PUR-HF Lift Trailing Cable isn't merely a conduit for power—it's a testament to human ingenuity, weaving safety, durability, and efficiency into the fabric of vertical mobility. From the thunderous depths of South African mines to the graceful ascents of urban elevators, it stands resilient against the odds. As industries evolve, embracing such innovations ensures not just progress, but protection. Whether you're an engineer spec'ing a hoist or a policymaker eyeing safety regs, the PUR-HF invites you to elevate—literally and figuratively.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430