Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

R-(N)TSCGEWÖU + FO Cable

R-(N)TSCGEWÖU + FO Cable: Flexible Reeling Cable with Fiber Optics for Mining and Industrial Use

Application | Specially designed flexible reeling cable with reduced dimensions for extremely high mechanical stresses in monospiral and cylindrical reels, high reeling speed, torsional stress. Used for large material handling machines (excavators, dumpers, crushers) in open-cast mines. Suitable for wet or dry conditions, industrial units, underground and open-cast mining, explosion-risk areas. |

Voltage Rating (Uo/U) | 3.6/6 (7.2)kV, 6/10 (12)kV, 8.7/15 (18)kV, 12/20 (24)kV |

Test Voltage | 11kV, 17kV, 24kV, 29kV |

Temperature Rating | Max. conductor operating temperature: +90°C |

Minimum Bending Radius | 6 x Outer diameter |

Conductor | Annealed class 5 flexible stranded tinned or bare copper |

Separator | Semi-conductive tape |

Conductor Screen | Semi-conductive layer of special rubber |

Insulation | Special EPDM rubber |

Insulation Screen | Semi-conductive, special strippable layer |

Earth Conductor | Class 5 tinned or bare copper with extruded special semi-conductive rubber compound |

Fiber Optic Module | A-D(ZN)13Y 6, 12, 18 or 24 fibers G50/125, G62.5/125 or E9/125 |

Inner Sheath | Special synthetic thermosetting compound type 5GM3 |

Anti-Torsion Braid | Braid of polyamide threads |

Outer Sheath | Special synthetic thermosetting compound 5GM5 |

Sheath Colour | Red |

Standards | DIN VDE 0250-813 IEC 60228 DIN VDE 0207/21 DIN VDE 0298-4 DIN VDE 0298-3 |

Flame Propagation | PN-EN 60332-1-2 IEC 60332-1-2 |

Oil Resistant | PN-EN 60811-404 IEC 60811-404 |

UV Resistant | UL 2556 ISO 4892-2 |

Ozone Resistant | PN-ISO 1431-1 |

Other Properties | Tear, Impact, and Abrasion Resistant |

Introduction to the R-(N)TSCGEWÖU + FO Cable

In the world of industrial engineering, where heavy machinery and extreme conditions dominate, the R-(N)TSCGEWÖU + FO Cable stands out as a pinnacle of innovation. Designed for applications requiring flexibility, durability, and high-performance data transmission, this cable integrates power and fiber optic capabilities to meet the rigorous demands of industries like mining, material handling, and heavy industrial units. Its ability to withstand mechanical stresses, torsional forces, and harsh environmental conditions makes it a preferred choice for high-stakes operations, including in South Africa’s booming mining sector.

Technical Specifications of the R-(N)TSCGEWÖU + FO Cable

The R-(N)TSCGEWÖU + FO Cable is a specially designed flexible reeling cable engineered for extreme mechanical stresses, such as those encountered in monospiral and cylindrical reels, high reeling speeds, and torsional stress. Below is a detailed breakdown of its technical specifications.

Voltage Ratings and Testing

The cable is available in multiple voltage ratings to suit various industrial needs:

3.6/6 (7.2) kV

6/10 (12) kV

8.7/15 (18) kV

12/20 (24) kV

Each rating undergoes rigorous test voltages of 11 kV, 17 kV, 24 kV, and 29 kV, respectively, ensuring reliability under high electrical loads.

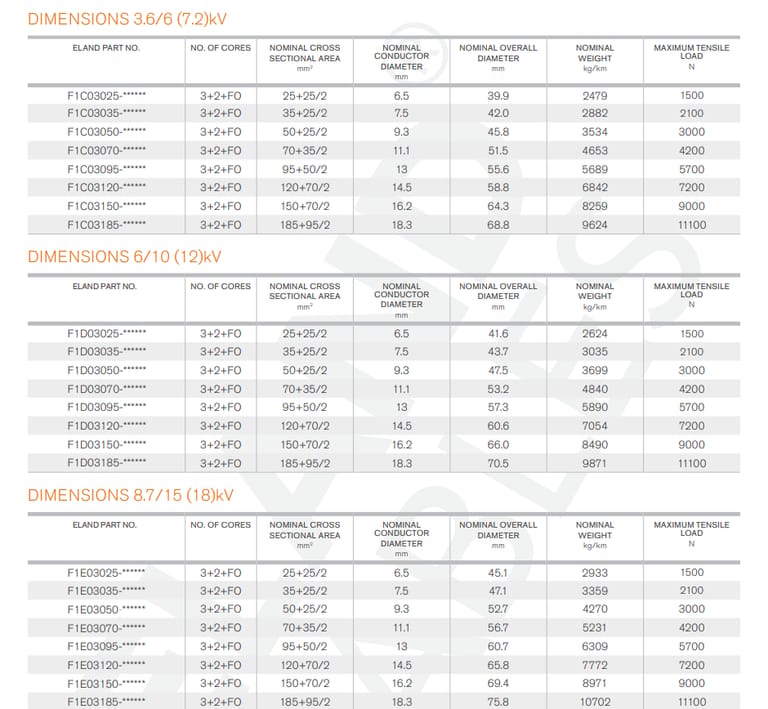

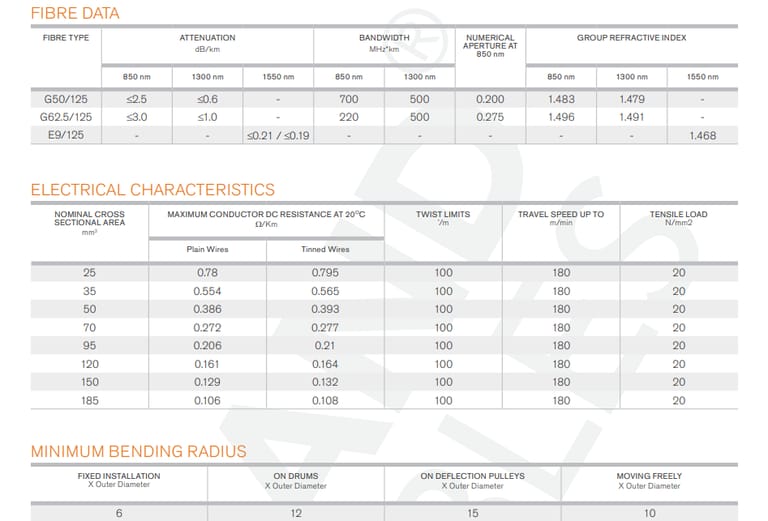

Dimensions and Configurations

The cable is available in multiple configurations, each with a combination of three power cores, two earth conductors, and a fiber optic module (denoted as 3+2+FO). The nominal cross-sectional areas range from 25+25/2 mm² to 185+95/2 mm², with corresponding conductor diameters, overall diameters, weights, and maximum tensile loads. For example:

3.6/6 kV, 25+25/2 mm²: Conductor diameter 6.5 mm, overall diameter 39.9 mm, weight 2479 kg/km, tensile load 1500 N.

12/20 kV, 185+95/2 mm²: Conductor diameter 18.3 mm, overall diameter 75.8 mm, weight 10702 kg/km, tensile load 11100 N.

Fiber Optic Module

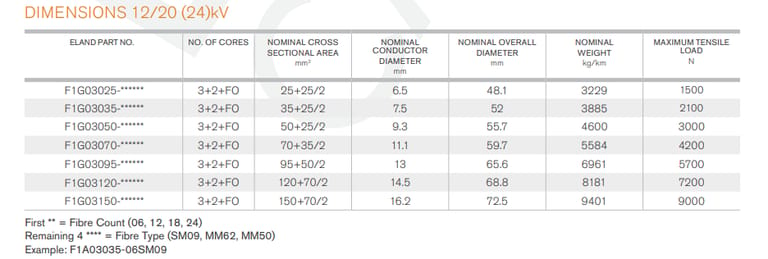

The cable integrates a fiber optic module (A-D(ZN)13Y) with options for 6, 12, 18, or 24 fibers, supporting three fiber types:

G50/125: Multimode, with attenuation ≤2.5 dB/km at 850 nm and ≤0.6 dB/km at 1300 nm, bandwidth 700 MHz*km at 850 nm.

G62.5/125: Multimode, with attenuation ≤3.0 dB/km at 850 nm and ≤1.0 dB/km at 1300 nm, bandwidth 220 MHz*km at 850 nm.

E9/125: Single-mode, with attenuation ≤0.21 dB/km at 1550 nm, suited for long-distance data transmission.

Electrical Characteristics

The cable’s conductors, made of annealed Class 5 flexible stranded tinned or bare copper, have low DC resistance, ensuring efficient power transmission. For example:

25 mm²: 0.78 Ω/km (plain wires), 0.795 Ω/km (tinned wires).

185 mm²: 0.106 Ω/km (plain wires), 0.108 Ω/km (tinned wires).

The cable supports a twist limit of 100°/m and travel speeds up to 180 m/min, with a tensile load capacity of 20 N/mm² across all configurations.

Construction Details

The cable’s robust construction enhances its durability:

Conductor: Annealed Class 5 flexible stranded tinned or bare copper.

Separator: Semi-conductive tape.

Conductor Screen: Semi-conductive layer of special rubber.

Insulation: Special EPDM rubber, known for its thermal and chemical resistance.

Insulation Screen: Semi-conductive, strippable layer.

Earth Conductor: Class 5 copper with extruded semi-conductive rubber.

Inner Sheath: Synthetic thermosetting compound (type 5GM3).

Anti-Torsion Braid: Polyamide threads for torsional stress resistance.

Outer Sheath: Red synthetic thermosetting compound (type 5GM5), UV, oil, ozone, tear, impact, and abrasion resistant.

Environmental and Mechanical Performance

Temperature Rating: Operates up to +90°C (conductor), +250°C (short circuit), and down to -40°C (fixed) or -25°C (mobile).

Minimum Bending Radius: 6x outer diameter (fixed), 10x (moving freely), 12x (on drums), 15x (on deflection pulleys).

Standards: Complies with DIN VDE 0250-813, IEC 60228, and flame propagation standards (IEC 60332-1-2).

Benefits of the R-(N)TSCGEWÖU + FO Cable

The R-(N)TSCGEWÖU + FO Cable offers several advantages that make it a standout choice for demanding applications:

Dual Functionality: Combines power transmission with high-speed fiber optic data communication, reducing the need for separate cables.

High Mechanical Strength: The anti-torsion braid and robust thermosetting sheaths ensure resilience against torsional stress, high reeling speeds, and abrasion.

Environmental Resistance: UV, oil, ozone, and flame resistance make it suitable for harsh environments like open-cast mines.

Flexibility: The Class 5 copper conductors and EPDM insulation allow for tight bending radii and dynamic movement.

Safety and Reliability: Compliance with international standards and high test voltages ensure safe operation in explosion-risk areas.

Usage Scenarios

The R-(N)TSCGEWÖU + FO Cable is tailored for applications involving extreme mechanical stresses and data transmission needs:

Open-Cast and Underground Mining: Powers and connects large equipment like excavators, dumpers, and crushers while transmitting operational data.

Material Handling: Supports high-speed reeling in monospiral and cylindrical reels for cranes and conveyors.

Industrial Units: Used in heavy industrial settings requiring reliable power and data under wet, dry, or explosive conditions.

Explosion-Risk Areas: Its robust construction ensures safety in hazardous environments.

Case in South Africa

South Africa’s mining industry, a cornerstone of the economy, provides a prime example of the cable’s application. Below are two case studies highlighting its impact.

Case: Enhancing Efficiency in a Limpopo Platinum Mine

In 2024, a major platinum mine in Limpopo faced challenges with frequent cable failures due to high torsional stress and abrasive conditions in its open-cast operations. By adopting the R-(N)TSCGEWÖU + FO Cable (12/20 kV, 95+50/2 mm², with 12-fiber G50/125 module), the mine achieved:

Reduced Downtime: The cable’s anti-torsion braid and abrasion-resistant sheath minimized failures, saving 20% in maintenance costs.

Improved Data Transmission: The fiber optic module enabled real-time monitoring of equipment performance, boosting operational efficiency by 15%.

Environmental Resilience: The cable withstood extreme heat and dust, maintaining performance in temperatures up to 40°C.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430