Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Reeling Fibre Optic Cable DIN VDE 0888

Understanding Reeling Fibre Optic Cables for Mining and Heavy Industry

Reeling Fibre Optic cable DIN VDE 0888

Applications | These cables are designed for the optical transmission of data and signals in tough operational conditions, such as on materials handling equipment (no reeling) or alongside conveyor belts etc., withstanding to high mechanical loads; suitable for outdoor and indoor use, also for hazardous environment. |

Standards | DIN VDE 0888 |

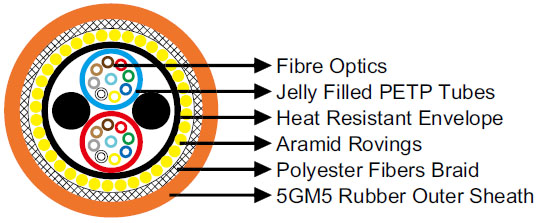

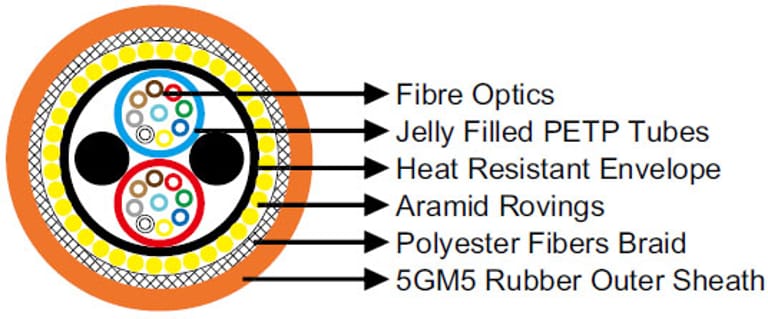

Construction  | |

Fiber Optics | Type: 9/125, 50/125 or 62.5/125. |

Plastic Tubes | PETP tubes filled with jelly. |

Envelope | Heat resistant compound. |

Stress Relief | Aramid rovings. |

Braid | Polyester fibers. |

Sheath | Rubber type 5GM5. |

Dimensions and Weight

Number of Fibers & Fibre Type | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

2×6G50/125 | 11 | 13 | 200 |

2×6G62.5/125 | 11 | 13 | 200 |

2×6E9/125 | 11 | 13 | 200 |

2×9G50/125 | 11 | 13 | 200 |

2×9G62.5/125 | 11 | 13 | 200 |

2×9E9/125 | 11 | 13 | 200 |

2×12G50/125 | 11 | 13 | 200 |

2×12G62.5/125 | 11 | 13 | 200 |

2×12E9/125 | 11 | 13 | 200 |

2×18G50/125 | 11 | 13 | 200 |

2×18G62.5/125 | 11 | 13 | 200 |

2×18E9/125 | 11 | 13 | 200 |

What Are Reeling Fibre Optic Cables?

Reeling fibre optic cables are a specialized class of flexible fibre optic cables designed to withstand constant movement, winding, and unwinding on reels or drums. Unlike fixed installation cables, these cables provide both mechanical robustness and data transmission reliability in environments where conventional fibre optics would fail.

Key design features include:

DIN VDE 0888 Compliance: Internationally recognized German standard ensuring durability and safe operation.

Optical Fibres: Available in single-mode (9/125 µm) and multi-mode (50/125 µm or 62.5/125 µm) configurations.

Mechanical Reinforcement: Stress relief via aramid rovings, reducing fibre strain during movement.

Protective Layers: PETP tubes filled with jelly for moisture resistance, polyester braid, and a durable rubber sheath type 5GM5 for abrasion resistance.

Benefits of Reeling Fibre Optic Cables

The adoption of reeling fibre optic cables offers multiple advantages for industries with high mechanical demands:

Durability in Harsh Conditions

Handles repetitive winding/unwinding cycles.

Resistant to mechanical stress, chemicals, and abrasions.

Reliable Data Transmission

Maintains signal integrity under constant motion.

Supports high-bandwidth and low-latency communication.

Safety and Standards Compliance

DIN VDE 0888 ensures reliability in safety-critical environments.

Reduces risk of unexpected cable failure during operation.

Operational Efficiency

Ensures uninterrupted monitoring and automation in mining and industrial processes.

Reduces downtime caused by cable damage.

Applications in Mining and Heavy Industry

Reeling fibre optic cables are widely used in environments where data transmission must remain stable despite constant motion.

1. Mining Sector

Underground Communications: Data transmission for automation, monitoring, and safety systems.

Conveyor Systems: Cables run alongside conveyors for continuous monitoring of material flow.

Draglines and Shovels: Used in open-pit mining for real-time data transfer between machinery and control rooms.

2. Ports and Materials Handling

Container cranes and ship loaders rely on reeling cables for operational data and control signals.

3. Industrial Automation

Robotics and automated systems in factories require reliable moving cable solutions.

Reeling fibre optic cables, manufactured according to DIN VDE 0888, are essential for industries where reliability, durability, and high-performance data transmission must coexist with harsh mechanical and environmental conditions. Their role in South African mining and heavy industry is growing rapidly, especially as the sector transitions towards automation, digitalization, and smart monitoring systems.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430