Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

RG7H1R Cable

RG7H1R Cable: a Robust Solution for South Africa’s Mining and Heavy Industry

RG7H1R

Application

The single core cables are designed for distribution of electrical power with nominal voltage Uo/U ranging from 1.8/3KV to 18/30KV and frequency 50Hz. They are suitable for installation mostly in power supply stations, indoors and in cable ducts, outdoors, underground and in water as well as for installation on cable trays for industries, switchboards and power stations.

Standards

IEC 60502 / CEI 20-13

Flame Retardant acc.to:

DIN VDE 0482 part 265-2-1

EN 50265-2-1

EN 60332-1-2

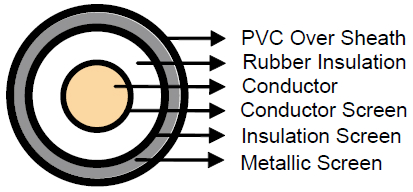

Construction

Conductor : Plain annealed copper with IEC 60228 class 2.

Conductor Screen : The conductor screen consists of an extruded layer of non metallic, semi-conducting compound firmly bonded to the insulation to exclude all air voids.

Insulation : Rubber, type G7 .

Insulaton Screen : The insulation screen consists of an extruded layer of non metallic, semiconducting compound extruded over the insulation. The extruded semi-conducting layer shall consist of bonded or cold strippable semi-conducting compound capable of removal for jointing or terminating. As an option, a semi-conducting tape may be applied over the extruded semi-conducting layer as a bedding for the metallic layer. The minimum thickness is 0.3 mm and the maximum resistivity is 500 Ohm-m at 90°C. The screen is tightly fitted to the insulation to exclude all air voids and can be easily hand stripped on site.

Over Sheath : Red(RAL 3000), PVC, type RZ, other dimensions and colours available on request.

Table 2a. Total Cross Section and Max. DC Resistance of Copper Wire Screen

Nom. Cross Section Area of Conductor | Total Cross Section | Max. DC Resistance at 20 ℃ | ||||

|---|---|---|---|---|---|---|

3.6/6KV (Um=7.2KV) | 6/10KV (Um=12KV) | 8.7/15KV (Um=17.5KV) | 12/20KV (Um=24KV) | 18/30KV (Um=36KV) | ||

mm² | mm | mm | mm | mm | mm | Ω |

10 | 10 | 10 | 10 | 10 | 10 | 1.075 |

16 | 16 | 16 | 16 | 16 | 16 | 1.075 |

25 | 16 | 16 | 16 | 16 | 16 | 1.075 |

35 | 16 | 16 | 16 | 16 | 16 | 1.075 |

50 | 16 | 16 | 16 | 16 | 16 | 1.075 |

70 | 16 | 16 | 16 | 16 | 16 | 1.075 |

95 | 16 | 16 | 16 | 16 | 16 | 1.075 |

120 | 16 | 16 | 16 | 16 | 16 | 1.075 |

150 | 25 | 25 | 25 | 25 | 25 | 0.688 |

185 | 25 | 25 | 25 | 25 | 25 | 0.688 |

240 | 25 | 25 | 25 | 25 | 25 | 0.688 |

300 | 25 | 25 | 25 | 25 | 25 | 0.688 |

400 | 35 | 35 | 35 | 35 | 35 | 0.491 |

500 | 35 | 35 | 35 | 35 | 35 | 0.491 |

630 | 35 | 35 | 35 | 35 | 35 | 0.491 |

800 | 50 | 50 | 50 | 50 | 50 | 0.344 |

1000 | 50 | 50 | 50 | 50 | 50 | 0.344 |

Table 2a. Total Cross Section and Max. DC Resistance of Copper Tape Screen (0.1mm)

Nom. Cross Section Area of Conductor | Total Cross Section & Max. DC Resistance | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

3.6/6KV (Um=7.2KV) | 6/10KV (Um=12KV) | 8.7/15KV (Um=17.5KV) | 12/20KV (Um=24KV) | 18/30KV (Um=36KV) | ||||||

Total Cross Section | Max. DC Resistance at 20 ℃ | Total Cross Section | Max. DC Resistance at 20 ℃ | Total Cross Section | Max. DC Resistance at 20 ℃ | Total Cross Section | Max. DC Resistance at 20 ℃ | Total Cross Section | Max. DC Resistance at 20 ℃ | |

mm² | mm |

| mm |

| mm |

| mm |

| mm |

|

10 | 4.7 | 3.646 | - | - | - | - | - | - | - | - |

16 | 5.1 | 3.342 | 5.9 | 2.925 | - | - | - | - | - | - |

25 | 5.7 | 3.025 | 6.4 | 2.679 | 7.3 | 2.350 | 8.1 | 2.114 | - | - |

35 | 6.2 | 2.796 | 6.9 | 2.498 | 7.8 | 2.210 | 8.6 | 2.000 | - | - |

50 | 6.7 | 2.568 | 7.4 | 2.314 | 8.3 | 2.064 | 9.1 | 1.880 | 11.2 | 0.579 |

70 | 7.4 | 2.314 | 8.2 | 2.106 | 9.1 | 1.897 | 9.9 | 1.740 | 11.9 | 0.543 |

95 | 8.2 | 2.095 | 8.9 | 2.925 | 9.8 | 1.748 | 10.7 | 1.614 | 12.7 | 0.510 |

120 | 9.0 | 1.905 | 9.8 | 2.679 | 10.7 | 1.613 | 11.5 | 1.498 | 13.5 | 0.479 |

150 | 9.7 | 1.781 | 10.4 | 2.498 | 11.3 | 1.523 | 12.1 | 1.420 | 14.2 | 0.458 |

185 | 10.6 | 1.626 | 11.2 | 2.314 | 12.2 | 1.407 | 12.9 | 1.335 | 14.9 | 0.434 |

240 | 11.7 | 1.465 | 12.4 | 2.106 | 2.106 | 1.294 | 14.1 | 1.219 | 16.2 | 0.401 |

300 | 12.9 | 1.334 | 13.4 | 1.923 | 1.923 | 1.204 | 15.1 | 1.139 | 17.1 | 0.378 |

400 | 14.3 | 1.205 | 14.6 | 1.761 | 1.761 | 1.110 | 16.3 | 1.054 | 18.4 | 0.353 |

500 | 15.7 | 1.094 | 16.2 | 1.655 | 1.655 | 1.005 | 17.5 | 0.982 | 20.0 | 0.325 |

630 | 17.3 | 0.992 | 18.9 | 1.540 | 1.540 | 0.918 | 19.5 | 0.880 | 21.6 | 0.300 |

800 | 20.3 | 0.849 | 20.4 | 1.388 | 21.3 | 0.807 | 22.1 | 0.777 | 24.2 | 0.268 |

1000 | 22.3 | 0.771 | 22.4 | 1.285 | 23.3 | 0.738 | 24.1 | 0.713 | 26.2 | 0.248 |

Physical Properties

Temperature Range : -15°C / +90°C

Max Short Circuit Temperature : +250°C

Min Installation Temperature : 0°C

Min Bending Radius : 12 x OD

Max. Tensile Stress : 60 N/mm²

Table 4. Nominal /Operating /Testing Voltages

Rated Voltage Uo/U | Operating Voltage (Um) | Testing Voltage (rms) |

|---|---|---|

1.8/3KV | 3.6KV | 6KV |

3.6/6KV | 7.2KV | 11KV |

6/10KV | 12KV | 17KV |

8.7/15KV | 17.5KV | 24KV |

12/20KV | 24KV | 29KV |

18/30KV | 36KV | 45KV |

*21/35KV and 26/35KV power frequency voltage test can be made under the following conditions: 2.5Uo x 30mins or 3.0Uo x 15mins. Numbers in brackets refer to the test values for 3.0Uo x 1.5mins.

What is the RG7H1R Cable?

The RG7H1R is a single-core, medium-voltage cable engineered for distributing electrical power in high-stakes settings. Its versatility allows it to be installed in power supply stations, indoors, outdoors, underground, in cable ducts, or even submerged in water. The cable’s construction, adhering to stringent international standards, makes it a preferred choice for industries such as mining, switchboards, and power stations.

Key Features

Nominal Voltage: Uo/U ranging from 1.8/3kV to 18/30kV.

Frequency: Designed for 50Hz systems.

Applications: Suitable for power supply stations, industrial settings, and cable trays.

Construction: Features a plain annealed copper conductor, rubber insulation (type G7), and a flame-retardant PVC oversheath.

Standards and Compliance

The RG7H1R cable complies with rigorous international standards, ensuring safety and performance:

IEC 60502 / CEI 20-13: These standards govern the cable’s design and performance for medium-voltage power distribution.

Flame Retardancy: The cable meets DIN VDE 0482 part 265-2-1, EN 50265-2-1, and EN 60332-1-2, ensuring it resists fire propagation, a critical feature in hazardous environments like mines.

These standards guarantee that the RG7H1R cable can withstand extreme conditions while maintaining operational integrity.

Technical Specifications

The RG7H1R cable’s technical specifications highlight its suitability for demanding applications:

Construction Details

Conductor: Plain annealed copper (IEC 60228 class 2), offering excellent conductivity.

Conductor Screen: An extruded semi-conducting compound eliminates air voids, enhancing insulation integrity.

Insulation: Rubber (type G7), providing flexibility and durability.

Insulation Screen: A semi-conducting compound, either bonded or strippable, with a minimum thickness of 0.3 mm and maximum resistivity of 500 Ohm-m at 90°C.

Oversheath: Red (RAL 3000) PVC (type RZ), customizable in color and dimensions.

Physical Properties

Temperature Range: Operates reliably from -15°C to +90°C.

Max Short Circuit Temperature: Up to +250°C.

Min Installation Temperature: 0°C.

Min Bending Radius: 12 x outer diameter (OD).

Max Tensile Stress: 60 N/mm².

Electrical Properties

The RG7H1R cable’s electrical performance varies by voltage rating and conductor cross-section. For example:

1.8/3kV (Um=3.6kV): Suitable for smaller industrial applications, with conductor sizes from 10 mm² to 630 mm².

18/30kV (Um=36kV): Designed for heavy-duty applications, supporting larger conductor sizes up to 1000 mm².

Key electrical data include DC and AC resistance, short-circuit ratings, capacitance, charging current, reactance, inductance, and impedance, as detailed in the provided tables. For instance, a 630 mm² conductor at 18/30kV has a DC resistance of 28 µΩ/m and a short-circuit rating of 91.2 kA for 1 second.

Copper Wire and Tape Screens

The cable features copper wire or tape screens to provide grounding and fault protection:

Copper Wire Screen: Cross-sections range from 10 mm² to 50 mm², with maximum DC resistance decreasing as conductor size increases (e.g., 1.075 Ω for 10 mm² to 0.344 Ω for 1000 mm²).

Copper Tape Screen: Thickness of 0.1 mm, with varying cross-sections and resistances depending on voltage rating.

Benefits of the RG7H1R Cable

The RG7H1R cable offers several advantages that make it ideal for South Africa’s mining and heavy industry sectors:

Durability: Its rubber insulation and PVC oversheath withstand harsh conditions, including moisture, heat, and mechanical stress.

Safety: Flame-retardant properties reduce fire risks, critical in confined spaces like underground mines.

Versatility: Suitable for diverse installation environments, from submerged applications to cable trays.

High Performance: Low resistance and high short-circuit ratings ensure reliable power delivery.

Customizability: Available in various conductor sizes and sheath colors to meet specific project needs.

Usage Scenarios in South Africa

South Africa’s mining and heavy industry sectors, particularly in regions like Gauteng and Mpumalanga, rely heavily on robust power distribution systems. The RG7H1R cable is well-suited for these applications due to its durability and compliance with safety standards.

Conclusion

The RG7H1R cable is a vital component in South Africa’s industrial and mining sectors, offering unmatched reliability, safety, and versatility. Its compliance with international standards, robust construction, and adaptability to diverse environments make it a top choice for powering critical operations. By following proper installation and maintenance practices, industries can ensure long-term performance and safety. As South Africa continues to advance its mining and heavy industry capabilities, the RG7H1R cable will remain a key player in driving progress and sustainability.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430