Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

RZ1-K XLPE LSZH Flexible Cable

Application | For installations where fire, smoke emission, and toxic fumes pose a threat to life and equipment. A flexible power and control cable designed for fixed applications with sinuous courses. |

Characteristics | |

Voltage Rating Uo/U | 0.6/1kV |

Temperature Rating | -15°C to +90°C |

Minimum Bending Radius | 5 x overall diameter |

Construction | |

Conductor | Class 5 flexible copper conductor |

Insulation | XLPE (Cross-Linked Polyethylene) |

Sheath | LSZH (Low Smoke Zero Halogen) |

Core Identification | |

3 Core | Green/Yellow, Blue, Brown |

4 Core | Green/Yellow, Brown, Black, Grey |

5 Core | Green/Yellow, Blue, Brown, Black, Grey |

7 Core | Black with White numbers |

Sheath Colour | Green (Black available on request) |

Standards | IEC 60502-1, EN 60228 |

Flame Retardant | IEC/EN 60332-1-2, IEC/EN 60332-3-24 |

Low Smoke Zero Halogen | IEC/EN 60754-1/2, IEC/EN 61034-1/2 |

Designed for fixed applications where fire, smoke emission, and toxic fumes pose existential threats to life and equipment, the RZ1-K is more than just a conduit for electricity—it's a lifeline. With its cross-linked polyethylene (XLPE) insulation and low smoke zero halogen (LSZH) sheath, this flexible power and control cable facilitates installations along sinuous courses, bending effortlessly where rigid alternatives would fail. As urban development surges in the Western Cape, bringing fire safety challenges to the forefront, and events like Firexpo 2025 highlight innovations in prevention, the RZ1-K emerges as a critical tool for engineers and safety officers.

Unraveling the Construction:

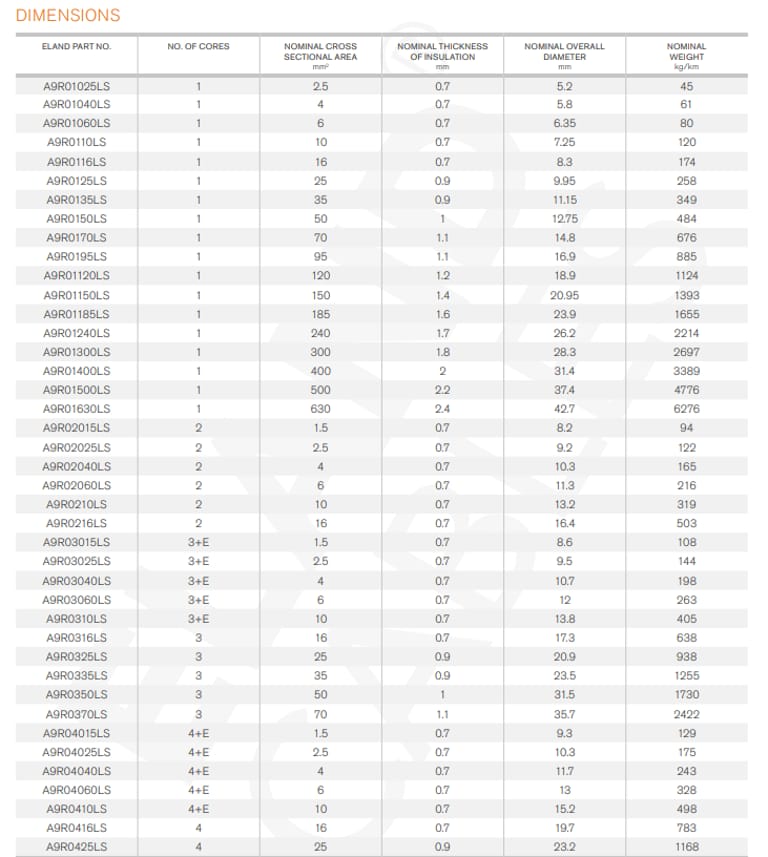

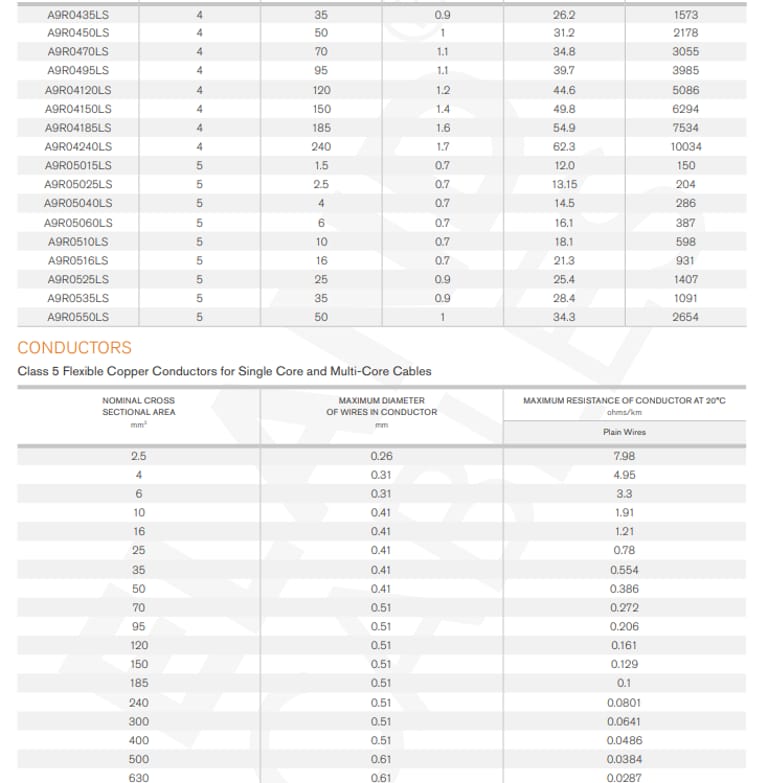

At its core—quite literally—the RZ1-K XLPE LSZH Flexible Cable is engineered for environments demanding both durability and adaptability. Let's start with the conductor: a Class 5 flexible copper conductor, the gold standard for multi-stranded wires that prioritize suppleness over stiffness. Unlike Class 2 conductors, which use fewer, thicker strands for rigidity, Class 5's fine, numerous wires (with maximum diameters as small as 0.26 mm for 2.5 mm² cross-sections) allow the cable to snake through tight bends in mining tunnels or control panels without kinking or fracturing.

Encapsulating these conductors is the XLPE insulation, a thermoset material where polyethylene molecules are cross-linked through a chemical process, creating a robust barrier against heat, moisture, and electrical stress. This isn't your average PVC jacket; XLPE's semi-crystalline structure withstands temperatures up to +90°C while operating at a voltage rating of Uo/U 0.6/1 kV—ideal for low- to medium-voltage fixed power distribution. The result? A dielectric strength that minimizes leakage currents and extends service life in humid, dusty conditions common to South African industrial sites.

The outer sheath steals the show in fire-prone settings: LSZH, a halogen-free compound that, when exposed to flames, emits minimal smoke and zero toxic halogens like chlorine or bromine. Traditional PVC or halogenated cables release dense, corrosive smoke that can blind evacuees and damage electronics; LSZH, compliant with IEC/EN 61034-1/2, keeps visibility clear and air breathable. Sheath color is standard green for easy identification in multi-core setups, with black available on request for UV-exposed outdoor runs.

Core identification follows intuitive color-coding: for three-core cables, green/yellow (earth), blue (neutral), and brown (phase); four-core adds black and grey; five-core incorporates those plus an extra grey; and seven-core uses black with white numerals for precision in complex control circuits. This setup ensures installers can quickly match phases during commissioning, reducing error risks in high-stakes deployments.

What makes the RZ1-K truly "flexible" is its minimum bending radius of just 5 times the overall diameter—far tighter than the 10-15x of armored cables. For a 10 mm diameter cable, that's a mere 50 mm bend, perfect for retrofitting in existing conduits without major disruptions. Manufactured to IEC 60502-1 and EN 60228 standards, every meter undergoes rigorous testing, from conductor resistance checks to sheath integrity scans, ensuring reliability from the factory floor to the field.

In essence, the RZ1-K's construction isn't a compromise between safety and flexibility—it's a synergy. By leveraging advanced polymer chemistry and fine-wire metallurgy, it addresses the trifecta of modern cabling needs: electrical efficiency, mechanical resilience, and fire mitigation.

Applications: Where Flexibility Meets Fire Resilience

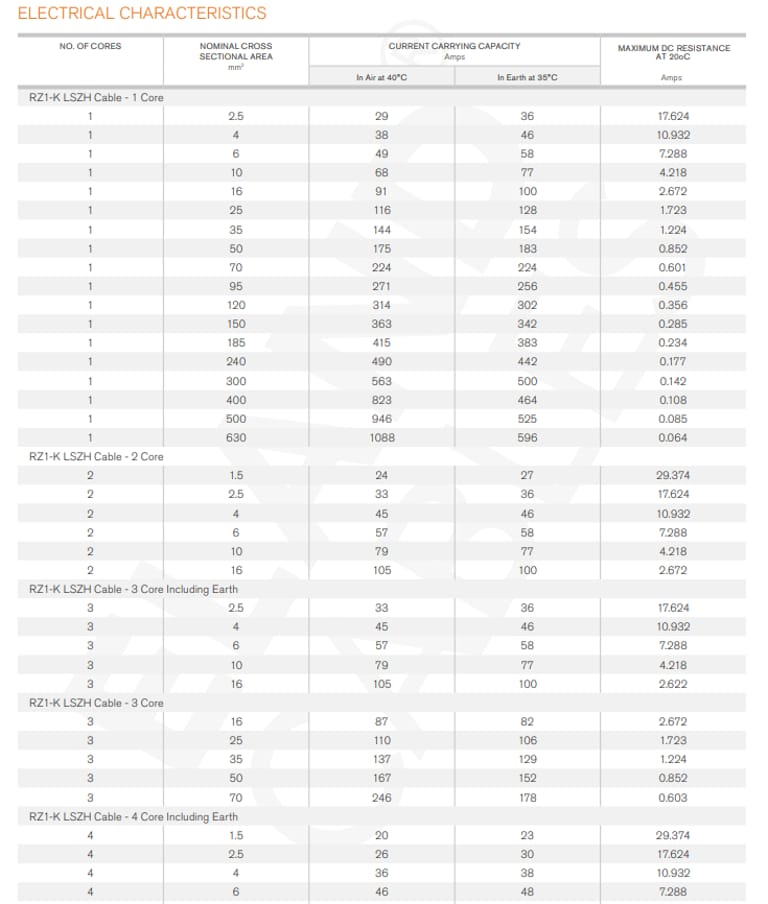

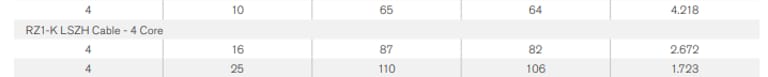

The RZ1-K thrives in fixed installations threatened by fire—think data centers, hospitals, tunnels, and offshore platforms—but its flexibility unlocks sinuous routing in constrained spaces. In power distribution, single-core variants feed motors or transformers; multi-core handles control signals with earth continuity. Its LSZH sheath shines in enclosed areas: during a fire, reduced smoke means faster egress, preserving visibility for emergency responders.

For South African contexts, it's tailor-made for mining conveyors, where cables snake along 5x diameter bends through ore chutes, or renewable substations enduring dust and vibration. The -15°C rating suits coastal fog, while +90°C handles solar inverter heat. Ultimately, the RZ1-K transforms potential hazards into secure pathways, embodying proactive engineering.

Case:

Renewable Energy: Powering the Green Grid Surge

South Africa's renewables are "rewiring" the future, with wave energy feasibility studies in Port Elizabeth and solar bids flooding Nersa. Yet challenges persist: the Electricity Regulation Amendment Act spurred progress, but grid integration demands resilient cabling amid dust storms and heat.

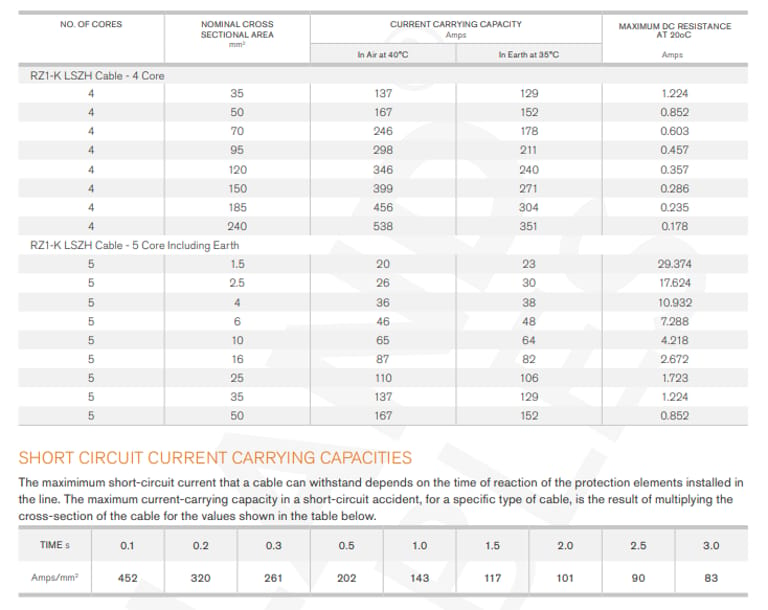

Consider the Redstone Solar PV Park expansion near Postmasburg, one of 111 Q1 registrations. For its 100 MW substation upgrade, developers deployed RZ1-K 3-core 70 mm² cables for inverter-to-transformer links. The XLPE insulation endured 50°C peaks, delivering 246 A in bundled trays with <1% voltage drop over 200 m. Flexibility proved key: sinuous routing around panel foundations avoided costly trenching, saving ZAR 500,000.

Fire risk, amplified by dry vegetation, was neutralized—LSZH sheaths passed bundled flame tests, echoing Firexpo 2025 demos. In a mock fault, smoke output stayed low, protecting control electronics. Electricals aligned perfectly: 0.601 ohms/km resistance minimized losses, boosting efficiency to 98%. This deployment not only met GreenCape's large-scale RE standards but accelerated commissioning by two weeks, injecting clean power amid load-shedding lulls.

Conclusion

The RZ1-K XLPE LSZH Flexible Cable isn't merely a product—it's a commitment to foresight in an unpredictable world. From mining depths to solar heights, its blend of flexibility, fire resistance, and performance empowers South Africa's 2025 triumphs over peril. By choosing such innovations, we don't just wire buildings; we safeguard futures. As the nation ignites progress, let the RZ1-K light the way—safely.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430