Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

SANS 1507-4 Steel Wired Armoured XLPE-PVC 0.6/1KV Cable

Why SANS 1507-4 Steel Wired Armoured XLPE-PVC 0.6/1kV Cables Are Essential for Safe, Reliable, and Efficient Power in South Africa’s Mining and Heavy Industry Sectors

SANS 1507-4 Steel Wired Armoured XLPE-PVC 0.6/1KV Cable

APPLICATION

Direct burial in free-draining soil conditions for fixed indoor and outdoor installations.

CHARACTERISTICS

Voltage Rating Uo/U 0.6/1kV

Temperature Rating Operating Temperature: -20 to +90 oC

Minimum Bending Radius 1.5mm2 to 16mm2 -

Fixed: 6 x overall diameter 25mm2 and above -

Fixed: 8 x overall diameter

CONSTRUCTION

Conductor: Copper conductor

Insulation: XLPE (Cross-linked Polyethylene)

Bedding: PVC (Polyvinyl Chloride)

Armour SWA: (Galvanized Steel Wire Armour)

Sheath: PVC (Polyvinyl Chloride)

Core Identification:

2 core: Red Yellow

3 core: Red Yellow Blue

4 core: Red Yellow Blue Black

Sheath Colour: Black with Red Stripe

STANDARDS:

SANS 1507-4

Flame Retardant according to IEC 60332-1-2

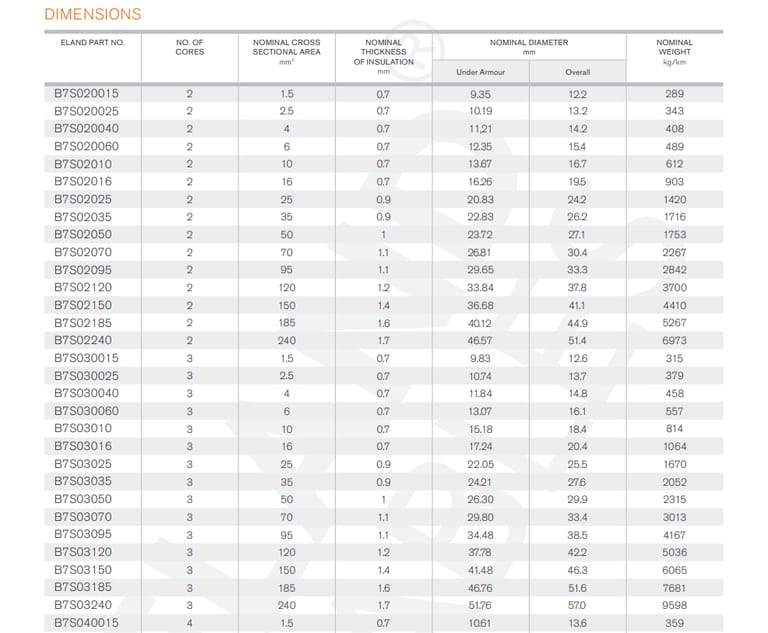

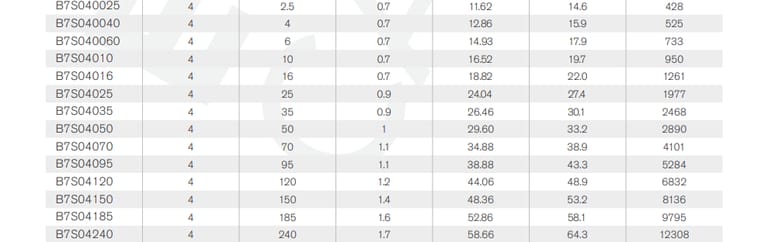

DIMENSIONS

What Is SANS 1507-4?

SANS 1507-4 is part of the South African National Standards for power cables. Specifically, Part 4 covers 0.6/1kV Steel Wire Armoured XLPE-PVC cables, which are designed for low-voltage power distribution in fixed installations.

These cables are flame-retardant, robust, and meet stringent safety requirements under IEC 60332-1-2 fire testing standards.

Benefits of Using SANS 1507-4 SWA XLPE-PVC Cables

Durability in Harsh Environments

Steel wire armour resists crushing, impact, and rodent attack.

Ideal for mining, construction, and industrial plants.

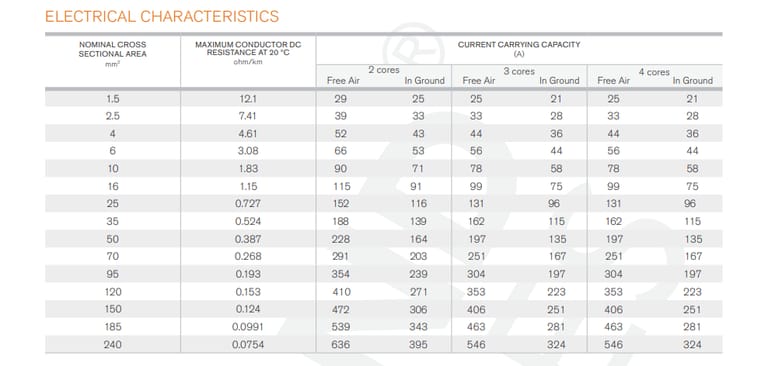

Thermal and Electrical Efficiency

XLPE insulation withstands higher temperatures (up to 90°C continuous, 250°C short-circuit).

Lower dielectric losses compared to traditional PVC insulation.

Fire Safety

Flame-retardant sheath minimizes fire hazards, critical in underground mines and factories.

Cost-Effectiveness

Long service life reduces replacement and maintenance costs.

Versatile Applications

Suitable for direct burial, outdoor exposure, and indoor fixed wiring.

Usage Scenarios in South Africa

Mining Industry

Gold Mines (Gauteng & Free State): Powering underground pumps and ventilation systems.

Platinum Mines (North West & Limpopo): Supplying electricity to conveyors and ore crushers.

Coal Mines (Mpumalanga): Used in conveyor belt systems and surface plants.

Heavy Industry

Steel Manufacturing Plants (Vanderbijlpark): Distributing power to furnaces and rolling mills.

Petrochemical Plants (Secunda): Safe power distribution in chemically aggressive environments.

Renewable Energy Projects: Connection between substations and industrial equipment.

Frequently Asked Questions (FAQ)

1. What is the difference between XLPE and PVC insulation?

XLPE has higher temperature tolerance and lower electrical losses than PVC, making it more efficient and durable.

2. Can these cables be used for overhead lines?

No, they are designed for direct burial and fixed installations, not for suspended or flexible applications.

3. Is the armour necessary for all installations?

In harsh environments like mines or outdoor areas, armour is critical for protection. In controlled indoor settings, unarmoured cables may suffice.

4. How long do SANS 1507-4 SWA XLPE-PVC cables last?

With proper installation and maintenance, they can last 30 years or more.

5. Do these cables meet international standards?

Yes, they comply with SANS 1507-4 and are flame-retardant according to IEC 60332-1-2, ensuring international compatibility.

The SANS 1507-4 Steel Wired Armoured XLPE-PVC 0.6/1kV Cable is more than just a power carrier—it is a safety-critical infrastructure component for South Africa’s mining and heavy industries. With its mechanical strength, fire resistance, and electrical reliability, it enables safe, efficient, and long-lasting power distribution under the country’s toughest operating conditions.

As South Africa continues to tackle energy challenges, mining modernization, and safety compliance, these cables will remain a cornerstone of industrial progress.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430