Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

SANS Type 622 / 622-ECC 12.7/22 kV Mining Cable

Understanding the Critical Role of SANS Type 622 and 622-ECC 12.7/22 kV Mining Cables in South Africa’s Heavy Industry and Energy Infrastructure

APPLICATION

Electrically driven machines, movable electric apparatus in hazardous areas, portable electric apparatus. Section feeders. Open cast mining, medium sized draglines, shovels and drills. Suitable for reeling purposes. Other industrial applications

CHARACTERISTICS

Voltage Rating Uo/U 12.7/22 kV

Temperature Rating -25°C to +90°C

Minimum Bending Radius 9 x Overall Diameter

STANDARDS

SANS 1520-2, SANS 1411-1, SANS 1411-3

UV resistant

Sunlight resistant

Oil resistant

CONSTRUCTION

Conductor: Class 5 flexible stranded tinned annealed Copper

Insulation: EPR (Ethylene Propylene Rubber) thermosetting compound and a strippable semi-conducting core screen (triple extruded)

Braid: Nylon /Tinned copper wires

Pilot Cores: Insulated with EPM (Ethylene Propylene Monomer)

Lay: Each power core individually screened with tinned copper/textile braid, laid up three insulated pilot cores

ECC Variant: One pilot core replaced with tinned conductor

Inner Sheath: CR (Polychloroprene Rubber)

Reinforcement braid: Open nylon braid - minimum 16 strings

Outer Sheath: CR (Polychloroprene Rubber)

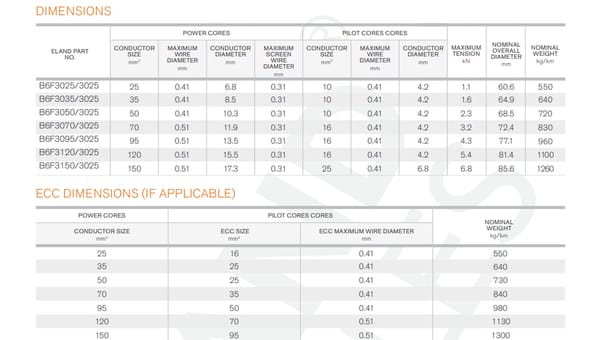

Dimensions

Mining and heavy industries in South Africa depend on reliable, high-performance electrical systems to power machinery in challenging environments. One of the most critical components in these systems is the power cable. Among the most widely applied solutions are the SANS Type 622 and 622-ECC 12.7/22 kV mining cables, designed to handle medium-voltage requirements for electrically driven machines, portable electric apparatus, and section feeders in both hazardous and open-cast mining environments.

Cable Types and Standards

The SANS Type 622 and 622-ECC cables are medium-voltage reeling and trailing cables rated at 12.7/22 kV. They are designed in compliance with SANS 1520-2, SANS 1411-1, and SANS 1411-3, ensuring they meet local safety, quality, and environmental standards. In addition, they are resistant to UV radiation, sunlight, and oil exposure—critical properties for cables used in harsh industrial environments.

The ECC variant (622-ECC) includes an Earth Continuity Conductor (ECC), which improves fault detection and provides enhanced protection in case of electrical failures.

Benefits of SANS Type 622/622-ECC Cables

Reliability: Engineered to withstand mechanical stress, high currents, and harsh environmental conditions.

Safety: ECC design enhances fault detection and grounding, reducing risks of electrical accidents.

Durability: Oil, UV, and abrasion resistance prolongs service life in tough mining conditions.

Flexibility: Suitable for reeling, trailing, and moving machinery.

Regulatory Compliance: Meets SANS standards, essential for NRCS approval in South Africa.

Installation Recommendations

Ensure a minimum bending radius of 9x the cable’s overall diameter during installation.

Avoid excessive mechanical stress, especially during reeling and trailing operations.

Use proper cable grips, clamps, and guides to prevent damage during movement.

Maintain correct tension and alignment when laying cables for draglines, shovels, and drills.

Install in compliance with SANS standards and manufacturer guidelines.

Maintenance Practices

Routine inspection and maintenance are vital for extending the service life of mining cables:

Visual Inspections: Regularly check for cuts, abrasions, and sheath damage.

Electrical Testing: Periodically test insulation resistance, continuity, and grounding integrity.

Repair Protocols: Address sheath damage promptly with proper repair kits to prevent moisture ingress.

Storage: Store cables in dry, shaded environments when not in use to prevent UV and moisture degradation.

Applications in South Africa’s Mining and Industrial Sectors

SANS Type 622 and 622-ECC cables are widely used in:

Open-Cast Mining: Powering draglines, shovels, and drills.

Hazardous Areas: Supplying portable and movable equipment where safety is paramount.

Section Feeders: Delivering power to medium-sized mobile machinery.

Reeling Applications: Withstanding mechanical stress in dynamic operations.

FAQ

1. What is the main difference between SANS Type 622 and 622-ECC cables?

The ECC variant includes an Earth Continuity Conductor, which improves grounding and fault protection.

2. Can these cables be used in reeling applications?

Yes, they are specifically designed for reeling and trailing purposes in mining equipment.

3. What standards do these cables comply with?

They comply with SANS 1520-2, SANS 1411-1, and SANS 1411-3.

4. What industries outside mining use these cables?

They are also used in heavy industry, construction, and energy infrastructure where medium-voltage mobility is required.

5. How do these cables contribute to worker safety?

By offering enhanced insulation, mechanical protection, and ECC grounding, they reduce the risk of electrical faults and accidents

The SANS Type 622 and 622-ECC 12.7/22 kV cables play a pivotal role in South Africa’s mining and heavy industry sectors, ensuring safe, reliable, and efficient power delivery under challenging conditions. Their robust construction, compliance with national standards, and adaptability for reeling and mobile machinery make them indispensable to operations that demand both performance and safety.

As the South African mining industry evolves, these cables will continue to support the drive towards safer, smarter, and more sustainable energy solutions.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430