Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

SANS Type 63 Flexible Copper Screened Mining Cable

SANS Type 63 Flexible Copper Screened Mining Cable: Engineered for underground mining operations in South Africa's demanding environments

Type 63 Flexible Copper Screened Mining Cable

Applications:

Electrically driven machines, movable electric apparatus in hazardous areas. Stackers, shearers, conveyor systems. Suitable for reeling purposes Other industrial applications.

STANDARDS:

SANS 1520-2

CHARACTERISTICS:

Excellent flexibility

Abrasion, tear resistant and flame retardant

Temperature range: minimum ambient temperature is -25℃. Maximum conductor temperature is +90℃.

UV, sunlight, ozone and oil resistant

Specifications

Cold Resistant -25℃

UV Resistance

Working Temperature 90℃

Oil Resistance

Flame Retardant

Construction

Conductor: Flexible class 5 comply to SANS 1411-1 from tinned annealed copper wires left lay

Insulation: Ethylene propylene thermosetting compound type RD 3 comply to SANS 1411-3

Insulation screen: The braid of tinned copper wires

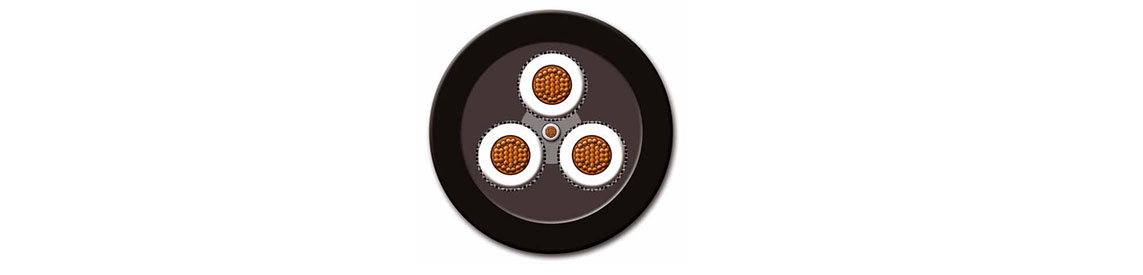

Cable assembly: Three tinned copper braided screened power cores and three unscreened pilot cores one in each interstice laid up in the right hand lay around semi-conductive cradle centre

Internal sheath: Poly-chloroprene thermosetting compound type RS 6 comply to SANS 1411-3

Reinforcing braid: An open nylon braid. Minimum 16 of nylon strings

Outer sheath: Poly-chloroprene thermosetting compound type RS 6 comply to SANS 1411-3. Inner and outer sheath are bonded to provide proper torsional protection, black

Parameter

Physical properties | |||||||||

Power cores | |||||||||

Conductor sizes (mm2) | 25 | 35 | 50* | 70 | 95 | 120 | 150 | 185 | 240 |

Maximum wire diameter (mm) | 0.41 | 0.41 | 0.41 | 0.51 | 0.51 | 0.51 | 0.51 | 0.51 | 0.51 |

Approximate conductor diameter (mm) | 6.8 | 8.5 | 10.3 | 11.9 | 13.5 | 15.5 | 17.3 | 20.2 | 22.9 |

Maximum screen wire diameter (mm) | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 |

Braided screen filling factor (%) | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 |

Approximate summarized screen cross-section for power cores | 31 | 33 | 38 | 42 | 47 | 50 | 55 | 60 | 64 |

Pilot cores | |||||||||

Conductor sizes (mm2) | 10 | 10 | 10 | 16 | 16 | 16 | 25 | 25 | 25 |

Maximum wire diameter (mm) | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 |

Approximate conductor diameter (mm) | 4.2 | 4.2 | 5.3 | 5.3 | 5.3 | 5.3 | 6.8 | 6.8 | 6.8 |

Lay ratio (maximum) (x PCD) | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

Cable diameter | |||||||||

Approximately (mm) | 44 | 48 | 50.5 | 56 | 61 | 63 | 66 | 72 | 78 |

Cable mass - approximately (kg/m) | 3.6 | 4.2 | 4.2 | 6.4 | 7.7 | 8.5 | 10.5 | 11.4 | 14.0 |

Minimum bending radius (mm) | 280 | 290 | 310 | 350 | 370 | 380 | 400 | 440 | 480 |

Maximum recommended tension (kN) | 1.1 | 1.6 | 2.3 | 3.2 | 4.3 | 5.4 | 6.8 | 8.3 | 10.8 |

Electrical properties | |||||||||

Power cores | |||||||||

Maximum cond. DC resistance at 200C (Ω/km) | 0.859 | 0.610 | 0.424 | 0.299 | 0.227 | 0.177 | 0.143 | 0.117 | 0.0882 |

Maximum cond. DC resistance at 900C (Ω/km) | 1.10 | 0.778 | 0.542 | 0.382 | 0.290 | 0.227 | 0.183 | 0.150 | 0.115 |

Reactance (Ω/km) | 0.122 | 0.113 | 0.107 | 0.103 | 0.090 | 0.088 | 0.085 | 0.084 | 0.083 |

Impedance (Z) at 900C (Ω/km) | 1.11 | 0.786 | 0.552 | 0.396 | 0.304 | 0.243 | 0.202 | 0.172 | 0.142 |

Sustained current rating at 300C ambient | |||||||||

Laid out straight (A) | 130 | 160 | 200 | 245 | 295 | 345 | 390 | 440 | 520 |

Short circuit rating | |||||||||

Symmetrical fault current (kA for 1 sec) | 3.1 | 4.3 | 6.1 | 8.5 | 11.6 | 14.6 | 18.3 | 23 | 29 |

Earth fault current - screens (kA for 1 sec) | 1.6 | 2.1 | 3.1 | 3.5 | 4.1 | 4.1 | 4.1 | 4.1 | 4.1 |

Benefits

The Type 63 cable is designed to address key challenges in mining environments, offering:

Flexibility: Reduces installation damage, extends lifespan in confined spaces, and cuts downtime by up to 20% compared to rigid cables.

Durability: Features abrasion-resistant sheaths and reinforcing braids to withstand impacts and chemicals in ore-rich environments.

Safety:

Copper screen minimizes electromagnetic interference (EMI), ensuring reliable automated system performance.

Flame-retardant per SANS standards, limiting fire spread in oxygen-poor tunnels.

90°C rating prevents insulation breakdown in hot climates, reducing shock hazards.

Efficiency and Sustainability: High-conductivity copper lowers energy losses, and durability minimizes replacement needs.

Installation Recommendations

To maximize performance:

Use reeling systems for trailing applications, respecting the minimum bending radius to prevent kinking.

Secure with clamps every 1-2 meters in vertical shafts to avoid sagging.

Inspect for sheath damage during setup and ensure correct connection of pilot cores for monitoring.

Maintenance Recommendations

To ensure a 10-15 year lifespan:

Conduct regular visual checks for abrasion, especially in high-traffic areas.

Perform electrical testing with megohmmeters to verify insulation integrity.

Clean with non-abrasive solvents to remove oils.

Store reels in shaded areas to protect against UV exposure.

In humid environments (e.g., South African mines), apply anti-corrosion sprays on exposed ends.

Follow SANS 1507 guidelines for periodic inspections.

Usage Scenarios

The Type 63 cable is optimized for:

Underground Mining:

Powers drilling rigs in narrow tunnels due to its flexibility.

Supports conveyor systems for uninterrupted material transport.

Powers ventilation fans in hot, dusty shafts, ensuring air quality per safety regulations.

Other Applications: Suitable for surface mining, material handling, and electrical tools.

Geographic Suitability: Excels in underground mining in countries like South Africa, Botswana, and Namibia.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430