Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

SANS Type 633 / 633-ECC 19/33 kV Mining Cable

How SANS Type 633 / 633-ECC 19/33 kV High-Voltage Cables Are Tackling Energy Crises, Enhancing Safety, and Driving Industrial Innovation in Heavy Sectors

SANS Type 633 / 633-ECC 19/33 kV

APPLICATION:

Electrically driven machines, movable electric apparatus in hazardous areas, portable electric apparatus. Section feeders. Open cast mining, medium sized draglines, shovels and drills. Suitable for reeling purposes. Other industrial applications.

CHARACTERISTICS:

Voltage Rating Uo/U 19/33 kV

Temperature Rating -25°C to +90°C

Minimum Bending Radius 9 x Overall Diameter

CONSTRUCTION:

Conductor : Class 5 flexible stranded tinned annealed Copper

Insulation: EPR (Ethylene Propylene Rubber) thermosetting compound and a strippable semi-conducting core screen (triple extruded)

Braid: Nylon /Tinned copper wires

Pilot Cores: Insulated with EPM (Ethylene Propylene Monomer)

Lay: Each power core individually screened with tinned copper/textile braid, laid up three insulated pilot cores

ECC Variant: One pilot core replaced with tinned conductor

Inner Sheath: CR (Polychloroprene Rubber)

Reinforcement braid: Open nylon braid - minimum 16 strings

Outer Sheath: CR (Polychloroprene Rubber)

STANDARDS:

SANS 1520-2

SANS 1411-1

SANS 1411-3

UV resistant

Sunlight resistant

Oil resistant

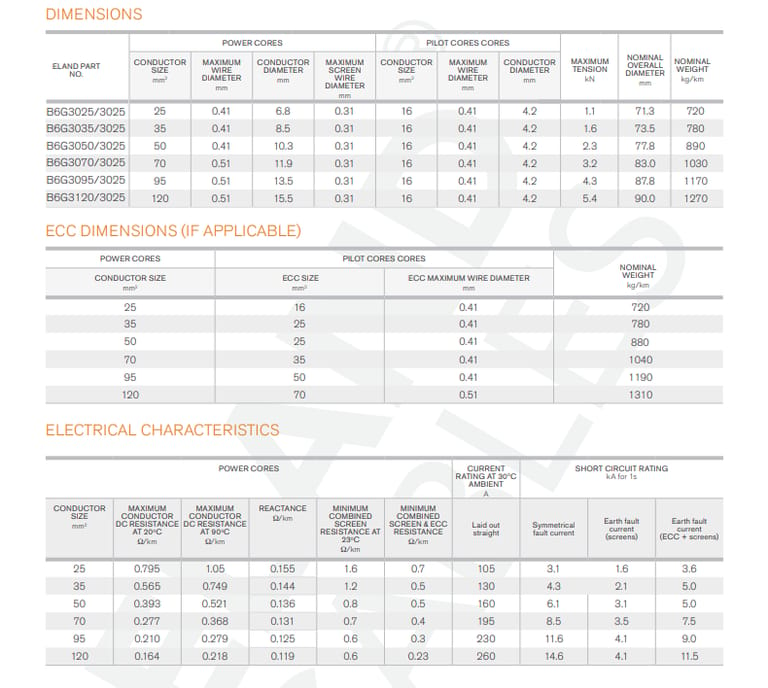

DIMENSIONS

Cable Types: SANS Type 633 vs. Type 633-ECC

Both SANS Type 633 and SANS Type 633-ECC belong to the same family of flexible medium-voltage mining cables rated at 19/33 kV. Their fundamental difference lies in the pilot core configuration:

Type 633: Equipped with three insulated pilot cores, which serve as auxiliary conductors for monitoring, control, or signaling.

Type 633-ECC: Replaces one pilot core with an earth continuity conductor (ECC), providing an additional safety mechanism to detect and interrupt faults.

This variation makes Type 633 suitable for applications requiring more control cores, while Type 633-ECC enhances electrical safety, especially in hazardous mining environments where fault detection is critical.

Key Benefits of SANS Type 633 / 633-ECC

High Voltage Capacity – Rated up to 33 kV, these cables meet the increasing demand for powering large mining machinery.

Flexibility and Durability – Class 5 stranded conductors and robust sheathing ensure the cable withstands constant movement and mechanical stress.

Enhanced Safety – Pilot cores and ECC integration allow real-time monitoring, fault detection, and earth continuity protection.

Environmental Resistance – Sunlight, UV, and oil resistance are essential for South African open-cast mines exposed to harsh climates.

Versatility – Suitable for draglines, shovels, drills, and movable apparatus across mining and heavy industrial applications.

Usage Scenarios in South Africa

1. Open-Cast Mining

Draglines, electric shovels, and drills require reliable high-voltage supply. Type 633 cables are widely used as section feeders due to their high flexibility and rugged design.

2. Hazardous Mining Areas

In coal mining regions like Mpumalanga, Type 633-ECC is often preferred for its enhanced earth continuity protection, reducing the risk of ignition from electrical faults.

3. Heavy Industrial Applications

Beyond mining, industries such as port operations and construction use Type 633 cables for powering mobile equipment requiring reeling or trailing connections.

Frequently Asked Questions (FAQ)

Q1: What is the voltage rating of SANS Type 633 cables?

A: They are rated at 19/33 kV, making them suitable for medium-voltage mining applications.

Q2: How is Type 633 different from Type 633-ECC?

A: The ECC version replaces one pilot core with an earth continuity conductor, improving fault detection and grounding safety.

Q3: Are these cables suitable for reeling?

A: Yes. Their flexible copper conductors and nylon braid reinforcement make them ideal for reeling and trailing applications.

Q4: What standards do these cables comply with?

A: They comply with SANS 1520-2, SANS 1411-1, and SANS 1411-3, ensuring compliance with South African safety and performance requirements.

Q5: How can mines extend the service life of these cables?

A: By respecting bending radii, conducting regular inspections, avoiding overloading, and performing preventive maintenance.

As South Africa’s mining industry pushes towards greater electrification and safety, the demand for reliable, high-performance cables is stronger than ever. SANS Type 633 and 633-ECC 19/33 kV cables stand out for their durability, flexibility, and compliance with stringent safety standards.

From powering draglines in Limpopo to shovels in Mpumalanga coal mines, these cables not only ensure continuous power delivery but also enhance worker safety and operational efficiency. With proper installation and maintenance, they can provide years of reliable service, making them indispensable for the future of mining and heavy industry in South Africa.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430