Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

SANS Type 66 Flexible Copper Screened Mining Cable

Type 66 Mining Trailing Cable: SANS 1520-2 Compliant Innovation Driving Safety, Durability, and Efficiency in South Africa's Harsh Mining and Heavy Industry Landscapes

Applications

Electrically driven machines, movable electric apparatus in hazardous areas, portable electric apparatus Section feeders. Open cast mining, medium sized draglines, shovels and drills. Suitable for reeling purposes.

Other industrial applications.

Standards:

SANS 1520-2

CHARACTERISTICS:

Excellent flexibility

Abrasion, tear resistant and flame retardant

Temperature range: minimum ambient temperature is -25℃. Maximum conductor temperature is +90℃.

UV, sunlight, ozone and oil resistant

Specifications

Cold Resistant -25℃

UV Resistance

Working Temperature 90℃

Oil Resistance

Flame Retardant

Construction

Conductor:

Flexible class 5 comply to SANS 1411-1 from tinned annealed copper wires, left hand with semi-conducting rubber screen

Insulation:

Ethylene propylene thermosetting compound type RD 3 comply to SANS 1411-3 and a strippable semi-conducting core screen (triple extruded)

Insulation screen:

The braid of tinned copper wires

Cable assembly:

Three tinned copper/nylon braid screened power cores and three unscreened pilot cores one in each interstice laid up in the right hand lay around semi-conductive filler centre. Alternatively, one pilot can be replaced with a tinned ECC conductor semi-conductive rubber covered)

Internal sheath:

Poly-chloroprene thermosetting compound type RS 6 comply to SANS 1411-3

Reinforcing braid:

An open nylon braid. Minimum 16 of nylon strings

Outer sheath:

Poly-chloroprene thermosetting compound type RS 6 comply to SANS 1411-3. Inner and outer sheath are bonded to provide proper torsional protection, black

Parameter

Physical Properties

Electrical Properties

Physical properties | |||||||||

Power cores | |||||||||

Conductor sizes (mm2) | 25 | 35 | 50 | 70 | 95 | 120 | 150 | 185 | 240 |

Maximum wire diameter (mm) | 0.41 | 0.41 | 0.41 | 0.51 | 0.51 | 0.51 | 0.51 | 0.51 | 0.51 |

Approximate conductor diameter (mm) | 6.8 | 8.5 | 10.3 | 11.9 | 13.5 | 15.5 | 17.3 | 20.2 | 22.9 |

Maximum screen wire diameter (mm) | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 |

Braided screen filling factor (%) | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

Approximate summarized screen cross-section for power cores | 28 | 29 | 32 | 35 | 39 | 41 | 44 | 47 | 50 |

Pilot cores | |||||||||

Conductor sizes (mm2) | 10 | 10 | 10 | 16 | 16 | 16 | 25 | 25 | 25 |

Maximum wire diameter (mm) | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 |

Approximate conductor diameter (mm) | 4.2 | 4.2 | 4.2 | 5.3 | 5.3 | 5.3 | 6.8 | 6.8 | 6.8 |

ECC size (if applicable) (mm2) | 16 | 25 | 25 | 35 | 50 | 70 | 95 | 95 | 120 |

ECC maximum wire diameter (if applicable) (mm) | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 | 0.51 | 0.51 | 0.51 | 0.51 |

Lay ratio (maximum) (x PCD) | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

Approxiamte cable diameter * (mm) | 50.1 | 51.7 | 55.3 | 59.8 | 64.6 | 68.8 | 73.1 | 77.8 | 83.1 |

Cable mass (approximate) | |||||||||

Type 66 (kg/m) | 3.8 | 4.2 | 5.1 | 6.2 | 7.4 | 8.7 | 10.2 | 11.7 | 14.1 |

Type 66 ECC (kg/m) | 3.9 | 4.4 | 5.5 | 6.4 | 7.6 | 8.9 | 10.5 | 11.9 | 14.5 |

Minimum bending radius (mm) | 430 | 450 | 480 | 520 | 550 | 590 | 650 | 670 | 740 |

Maximum recommended tension (kN) | 1.1 | 1.6 | 2.3 | 3.2 | 4.3 | 5.4 | 6.8 | 8.3 | 10.8 |

Electrical properties | |||||||||

Power cores | |||||||||

Maximum cond. DC resistance at 200C (Ω/km) | 0.795 | 0.565 | 0.393 | 0.277 | 0.210 | 0.164 | 0.132 | 0.108 | 0.0817 |

Maximum cond. DC resistance at 900C (Ω/km) | 1.05 | 0.749 | 0.521 | 0.368 | 0.279 | 0.218 | 0.176 | 0.145 | 0.110 |

Reactance (Ω/km) | 0.124 | 0.116 | 0.109 | 0.105 | 0.101 | 0.096 | 0.092 | 0.091 | 0.087 |

Impedance (Z) at 900C (Ω/km) | 1.06 | 0.758 | 0.532 | 0.383 | 0.297 | 0.238 | 0.199 | 0.171 | 0.140 |

Minimum combined screen resistance at 230C (Ω/km) | 1.6 | 1.2 | 0.8 | 0.7 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

Minimum combined screen & ECC resistance (Ω/km) | 0.7 | 0.5 | 0.5 | 0.4 | 0.3 | 0.23 | 0.18 | 0.18 | 0.15 |

Sustained current rating at 300C ambient | |||||||||

Laid out straight (A) | 105 | 130 | 160 | 195 | 230 | 260 | 300 | 340 | 400 |

Short circuit rating | |||||||||

Symmetrical fault current (kA for 1 sec) | 3.1 | 4.3 | 6.1 | 8.5 | 11.6 | 14.6 | 18.3 | 23 | 29 |

Earth fault current - screens (kA for 1 sec) | 1.6 | 2.1 | 3.1 | 3.5 | 4.1 | 4.1 | 4.1 | 4.1 | 4.1 |

Earth fault current - ECC + screens (kA for 1 sec) | 3.6 | 5.0 | 5.0 | 7.5 | 9.0 | 11.5 | 14.0 | 14.0 | 17.0 |

Understanding the Type 66 Mining Trailing Cable: A Primer on Cable Types

At its core, the Type 66 Mining Trailing Cable is a flexible, medium-voltage power cable engineered for trailing applications—meaning it's designed to be dragged, reeled, and flexed repeatedly without failing. Unlike rigid cables used in fixed installations, trailing cables must endure constant movement, making them indispensable in dynamic settings like open-cast mining or underground operations.

The Type 66 falls under the broader category of elastomeric cables, which use rubber-like materials for insulation and sheathing to provide elasticity and resilience. Specifically, it's rated for voltages between 3.8 kV and 6.6 kV, bridging the gap between low-voltage cables (like Type 63 at 1.9/3.3 kV) and higher-voltage options. This voltage range makes it suitable for powering medium-sized equipment in mines, where higher power demands require robust yet flexible conductors.

There are variations within the Type 66 family, such as the standard Type 66 and the Type 66 ECC (Earth Continuity Conductor). The ECC version incorporates an additional tinned earth continuity conductor, enhancing grounding and safety in environments prone to electrical faults. Both types adhere to SANS 1520-2, which specifies requirements for flexible cables in hazardous areas, ensuring they meet South African safety and performance benchmarks. In comparison to Type 63, the Type 66 handles higher voltages with similar construction but upgraded materials for greater tensile strength and thermal resistance.

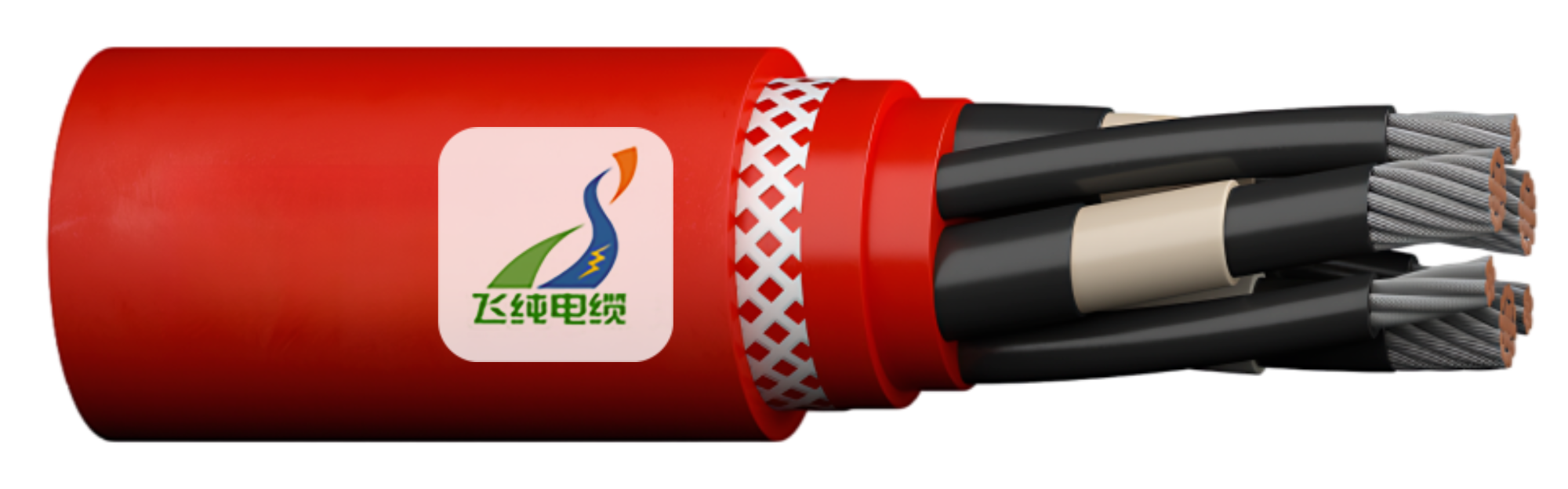

To appreciate its design, consider the cable's layered anatomy. The conductor is made from flexible Class 5 tinned annealed copper wires, compliant with SANS 1411-1, offering excellent conductivity while resisting corrosion. A semi-conducting rubber screen surrounds it, preventing electrical stress concentrations. Insulation comes from ethylene propylene rubber (EPR) type RD 3, known for its thermosetting properties that maintain integrity under heat. A braided screen of tinned copper wires adds electromagnetic interference protection, while pilot cores—unscreened for monitoring—sit in the interstices.

The assembly features three power cores and three pilot cores laid around a semi-conductive filler, with an internal sheath of polychloroprene rubber (CR) type RS 6 for torsional protection. An open nylon braid reinforces it, and the outer sheath, also CR type RS 6, bonds to the inner layer for added durability. This construction ensures the cable is UV, ozone, oil, and flame resistant, with a temperature range from -25°C to +90°C—perfect for South Africa's variable climates, from freezing highveld winters to sweltering mine depths.

Benefits: Why Type 66 Stands Out in South Africa's Mining Sector

The Type 66's benefits are multifaceted, directly addressing industry pain points. First, its exceptional flexibility—thanks to Class 5 conductors and rubber compounds—reduces fatigue from repeated bending, minimizing downtime in operations where cables are reeled daily. In South Africa's coal mines, where temperatures can exceed 40°C, the +90°C rating prevents thermal degradation, extending service life by up to 50% compared to standard cables.

Abrasion and tear resistance, bolstered by the CR sheath and nylon braid, combat the rough terrains of open-cast sites. Flame retardancy is vital amid rising fire risks from illegal mining activities, which often involve unsafe electrical setups. UV and ozone resistance ensure outdoor longevity, while oil resistance guards against spills from hydraulic systems.

Safety-wise, the semi-conducting screens and ECC option prevent electrical shocks, aligning with SANS 1520-2's emphasis on hazardous areas. This reduces accident risks in an industry where fatalities from equipment failures persist. Economically, lower maintenance needs and reduced replacements cut costs—crucial as input expenses rise. Amid energy crises, reliable power transmission helps mitigate outage impacts by ensuring equipment restarts smoothly.

Environmentally, the cable's durable design reduces waste from frequent replacements, supporting sustainability trends like those in the Critical Minerals and Metals Strategy 2025.

Installation and Maintenance Recommendations: Best Practices for Longevity

Proper installation is key to harnessing the Type 66's potential. Start with site assessment: measure reeling paths to ensure bending radii aren't exceeded (e.g., 430-740 mm minimum). Use specialized reeling drums to avoid kinks, and secure ends with strain-relief clamps to distribute tension.

During laying, avoid sharp edges; use rollers for dragging. For underground use, suspend cables where possible to prevent abrasion. Electrical testing—insulation resistance and continuity—should precede energization, per SANS guidelines.

Maintenance involves regular inspections: check for cuts, swelling, or discoloration every shift in high-stress areas. Clean with non-abrasive solvents to remove dust and oils. Monitor temperature with infrared thermography to spot hotspots. Reeling systems should be lubricated, and cables stored coiled in shaded areas to prevent UV damage.

In South Africa's context, where skills shortages loom, training programs on cable handling can prevent misuse. Predictive maintenance using IoT sensors for vibration and tension can preempt failures, aligning with digital trends in African mining.

Usage Scenarios: From Mines to Heavy Industry

The Type 66 shines in open-cast mining for medium-sized draglines and shovels, where it's reeled to follow moving machinery. In coal operations like those in Mpumalanga, it powers excavators amid dusty, abrasive conditions.

Beyond mining, it's used in portable electric apparatus and section feeders in hazardous industrial zones. For instance, in tunneling or quarrying, it supplies drills under mechanical stress.

A hypothetical yet realistic case study: In a KwaZulu-Natal coal mine hit by 2025's energy shortages, frequent outages caused cable overheating in older systems, leading to downtime costing R500,000 daily. Switching to Type 66 reduced failures by 70%, thanks to its thermal resilience, allowing seamless integration with backup generators.

Another example draws from broader trends: In PGM mines facing illegal intrusions, robust cables like Type 66 minimize risks from tampered infrastructure. A 2024 incident in a Limpopo mine, where corroded cables sparked a fire (similar to reported corrosion cases), underscores the need; post-upgrade to Type 66, safety improved markedly.

In heavy industry, such as steel plants, it powers movable cranes, enduring oil and heat. Amid South Africa's push for critical minerals, the cable supports electrified equipment in green mining initiatives.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430