Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Single-core 1900/3300 V cables with circular stranded copper conductor

APPLICATION

These cables are used for power and control circuits, they can offer excellent protection through the use of a heavy galvanized steel wire armour, so they are well adapted to underground use in industrial applications, in moist areas.

CONSTRUCTION

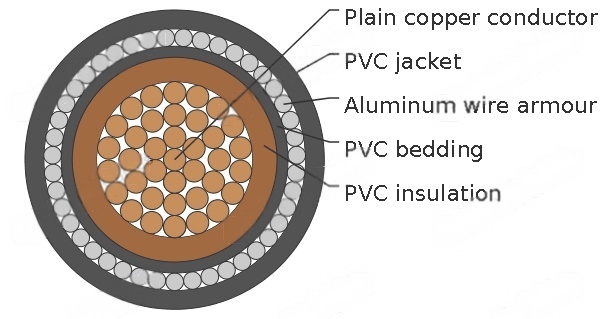

Conductor | Solid Aluminum or Copper conductor, round stranded or shaped, Class 2 to BS 6460, IEC 60228. |

Insulation | PVC(Polyvinyl Chloride) type TI1 |

Colour Code | 1 Core : Brown |

2 Cores : Brown or Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green-yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Filler(optional) | PVC or Polypropylene yarn |

Binder Tape(optional) | Polyester (Mylar) tape |

Inner Sheath/Bedding | PVC (Polyvinyl Chloride) |

Armour | Single Core : AWA (Aluminum WireArmour) |

Multi Core : SWA (Steel Wire or Tape Armour) | |

Outer Sheath | PVC(Polyvinyl Chloride), type TM1 |

TECHNICAL INFORMATION

Voltage rating | 1900/3300V |

Temperature rating | -20°C to +60°C |

Bending radius | Single core : 10 x overall diameter |

Multicores : 8 x overall diameter | |

Flame retardant | IEC60332 part 1, BS4066 part 1 |

CABLE PARAMETER

Nominal cross-sectional area | Number/wire | Nominal insulation thickness | Nominal bedding thickness | Nominal alum wire armor dia. | Nominal sheath thickness | Approx.overall diameter | Approx.cable weight |

|---|---|---|---|---|---|---|---|

mm² | No./mm | mm | mm | mm | mm | mm | kg/mm |

19/1.78 | 2.2 | 0.8 | 1.25 | 1.6 | 21.0 | 840 | |

19/2.14 | 2.2 | 0.8 | 1.25 | 1.6 | 22.8 | 1070 | |

19/2.52 | 2.2 | 1.0 | 1.6 | 1.7 | 26.0 | 1445 | |

37/2.03 | 2.2 | 1.0 | 1.6 | 1.7 | 27.7 | 1715 | |

37/2.25 | 2.2 | 1.0 | 1.6 | 1.8 | 29.4 | 2010 | |

37/2.52 | 2.2 | 1.0 | 1.6 | 1.8 | 31.3 | 2380 | |

61/2.25 | 2.2 | 1.0 | 1.6 | 1.9 | 34.1 | 2975 | |

61/2.52 | 2.4 | 1.0 | 1.6 | 1.9 | 37.0 | 3615 | |

61/2.85 | 2.6 | 1.2 | 2.0 | 2.1 | 42.0 | 4655 | |

61/3.20 | 2.8 | 1.2 | 2.0 | 2.1 | 45.6 | 5725 | |

61/3.65 | 2.8 | 1.2 | 2.0 | 2.2 | 49.7 | 7150 | |

127/2.85 | 2.8 | 1.4 | 2.5 | 2.4 | 55.8 | 9160 | |

127/3.20 | 3.0 | 1.4 | 2.5 | 2.5 | 61.0 | 11400 |

Introduction

Have you ever wondered how electricity powers the massive machinery in South Africa's mines, factories, and processing plants without faltering, even in harsh underground conditions? The answer often lies in specialised cables designed to withstand the rigours of industrial use. Single-core 1900/3300 V cables with circular stranded copper conductors are a prime example, offering robust protection and reliable performance in environments prone to moisture and mechanical stress. These cables, commonly used for power and control circuits, are particularly suited for underground installations where durability is paramount.

In South Africa, where industries like mining and manufacturing drive the economy, these cables play a crucial role in ensuring uninterrupted power supply. They adhere to standards such as SANS 1507, which promotes quality and safety in electrical installations.

Understanding Single-Core 1900/3300 V Cables

Single-core cables, as the name suggests, feature a single conductor, making them ideal for applications where space is limited or where magnetic interference must be minimised. Rated at 1900/3300 V, these cables operate in the medium voltage range, suitable for distributing power in industrial setups. The "1900/3300 V" rating indicates the maximum voltage between conductor and earth (1900 V) and between conductors (3300 V), ensuring they handle the demands of 3.3 kV systems common in South African industries.

What sets these cables apart is their circular stranded copper conductor. Unlike solid conductors, stranded designs consist of multiple thin wires twisted together, providing flexibility and resistance to breakage under bending or vibration. Copper is chosen for its excellent electrical conductivity, which minimises energy loss during transmission. In fact, copper's conductivity is about 60% higher than aluminium, making it preferable for high-current applications where efficiency matters.

These cables are often armoured with Aluminium Wire Armour (AWA), a non-magnetic material that prevents overheating from induced currents in alternating current (AC) systems. This is critical for single-core designs, as steel armour (used in multi-core cables) could generate magnetic fields leading to energy losses or safety hazards. In South Africa, compliance with SANS 1507 ensures these cables meet local safety and performance requirements, including flame retardancy and environmental resilience.

Applications in Industrial Settings

These cables excel in power and control circuits, particularly underground in industrial applications where moisture is a concern. In South Africa, they're vital for mining operations in the Witwatersrand Basin or manufacturing plants in Gauteng, where damp conditions prevail. The AWA armour shields against water ingress and physical impacts from machinery or earth shifts.

For instance, in petrochemical plants or water treatment facilities, these cables distribute power to pumps and motors without risking short circuits. Their single-core design allows for trefoil arrangements in three-phase systems, reducing electromagnetic interference. Unlike multi-core cables, they offer better heat dissipation, crucial in confined spaces.

In construction, they're used for temporary power setups, and in renewable energy projects like solar farms, they connect inverters to grids. South African regulations, including SANS 10198-12 for installation, mandate proper burial depths to prevent damage.

Advantages and Considerations

Why choose copper conductors? Beyond conductivity, copper offers durability against corrosion, high tensile strength for pulling during installation, and better weldability for joints. In medium voltage applications, it reduces energy losses, potentially saving costs in large-scale operations. Compared to aluminium, copper handles higher loads with less cross-section, ideal for space-constrained underground tunnels.

The AWA armour is a game-changer, providing mechanical protection without magnetic issues. In South Africa's variable climate, PVC sheathing resists moisture, but for enhanced fire safety, variants with Low Smoke Zero Halogen (LSZH) are available under BS 6724.

However, considerations include cost—copper is pricier than aluminium—and weight, which affects handling. In South Africa, adherence to NRCS regulations ensures compulsory safety standards. Overall, these cables balance performance and reliability, making them indispensable for sustainable industrial growth.

Frequently Asked Questions

Here are answers to common queries about single-core armoured cables:

What is the difference between AWA and SWA cables? AWA uses aluminium wires, ideal for single-core to avoid magnetic heating, while SWA (steel) is for multi-core.

Can these cables be used outdoors? Yes, but they're best for underground or protected installations due to their armour and PVC sheath.

Why not use steel armour on single-core cables? Steel can induce eddy currents, causing overheating in AC systems.

How deep should they be buried? Per SANS 10198-12, sufficient depth to avoid damage, typically 0.6–1 m, depending on location.

Are they suitable for high-voltage applications? They're rated for 3.3 kV; for higher, consult standards like SANS 1520.

What are the benefits over multi-core cables? Better flexibility in design, improved heat dissipation, and reduced interference.

How do I cut armoured cable safely? Use specialised tools like hacksaws or cable cutters, ensuring to strip layers carefully to avoid damaging the conductor.

Is XLPE better than PVC insulation? XLPE offers higher temperature ratings, but PVC is sufficient for many applications and more cost-effective.

Single-core 1900/3300 V cables with circular stranded copper conductors are more than just components—they're the backbone of reliable industrial power in South Africa. Their robust construction, from copper cores to AWA armour, ensures they thrive in challenging underground environments, supporting the nation's economic engines. As industries evolve towards sustainability, these cables, compliant with SANS standards, will continue to play a pivotal role. Whether you're planning an installation or simply curious, understanding these cables highlights the ingenuity behind everyday electricity.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430