Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Single-core 1900/3300V cables with circular stranded copper conductor

APPLICATION

These cables are used for power and control circuits, they can offer excellent protection through the use of a heavy galvanized steel wire armour. The GSWA makes them suitable for use inside and outside buildings or for direct burial in the ground. For installation where fire, smoke emission and toxic fumes create a potential threat to life and equipment.

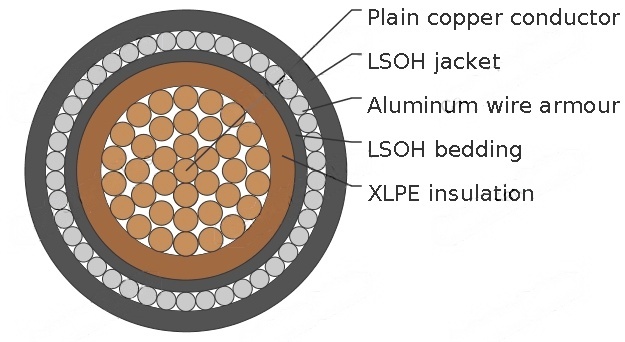

CONSTRUCTION

Conductor | Solid Aluminum or Annealed Copper conductor, circular or shaped, Class 2 to BS EN60228. |

Insulation | XLPE (Cross-Linked Polyethylene) Type GP 8 conforming to BS 7655-1.3 or type GP 6 conforming to BS 7655-1.2. |

Colour Code | 1 Core : Brown or Blue |

2 Cores : Brown, Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green/Yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Bedding | The bedding shall consist of an extruded layer of polymeric material consistent with the operating temperature of the cable. |

Armour | Single Core : AWA (Aluminum Wire Armour) |

Multi Core : GSWA (Galvanized Steel Wire Armour) | |

Outer Sheath | LSOH (Low Smoke Zero Halogen),conforming to BS 7655-6.1. |

TECHNICAL INFORMATION

Voltage rating | 1900/3300V |

Temperature rating | 0°C to +90°C |

Min. Bending radius | 8 x overall diameter |

Flame retardant | BS EN 60332-1-2 ; BS EN 60332-3-24:2009 |

Halogen free | BS EN 60754-1 |

Smoke density | BS EN 61034-2 |

CABLE PARAMETER

Nominal Cross-sectional Area | Strand Type | Nominal Insulation Thickness | Nominal Bedding Thickness | Nominal Alum Wire Armor dia. | Nominal Sheath Thickness | Approx. Overall Diameter | Aprrox. Weight |

|---|---|---|---|---|---|---|---|

mm² | No./mm | mm | mm | mm | mm | mm | kg/km |

19/1.78 | 2 | 0.8 | 1.25 | 1.6 | 20.6 | 790 | |

19/2.14 | 2 | 0.8 | 1.25 | 1.6 | 22.4 | 1040 | |

19/2.52 | 2 | 0.8 | 1.25 | 1.6 | 24.3 | 1330 | |

37/2.03 | 2 | 1 | 1.6 | 1.7 | 27.2 | 1680 | |

37/2.25 | 2 | 1 | 1.6 | 1.7 | 28.8 | 1970 | |

37/2.52 | 2 | 1 | 1.6 | 1.8 | 30.8 | 2370 | |

61/2.25 | 2 | 1 | 1.6 | 1.8 | 33.5 | 2960 | |

61/2.52 | 2 | 1 | 1.6 | 1.9 | 36.1 | 3610 | |

61/2.85 | 2 | 1.2 | 2 | 2 | 40.5 | 4600 | |

61/3.20 | 2.2 | 1.2 | 2 | 2.1 | 44.2 | 5680 | |

127/2.52 | 2.4 | 1.2 | 2 | 2.2 | 48.8 | 7160 | |

127/2.85 | 2.6 | 1.4 | 2.5 | 2.4 | 55.4 | 9150 | |

127/3.20 | 2.8 | 1.4 | 2.5 | 2.5 | 60.6 | 11270 |

Introduction

In the realm of electrical engineering, cables form the backbone of power distribution systems, ensuring the safe and efficient transmission of electricity across various sectors. Among these, single-core 1900/3300V armoured cables with circular stranded copper conductors stand out for their robustness and versatility. These cables, often rated at 3.3kV, are designed for medium-voltage applications where reliability is paramount. They incorporate advanced materials like cross-linked polyethylene (XLPE) insulation and low smoke zero halogen (LSZH) outer sheathing, making them suitable for environments where fire safety and mechanical protection are critical.

Applications in Diverse Sectors

Single-core 1900/3300V cables excel in power and control circuits, offering protection for indoor, outdoor, or direct burial installations. In South Africa, they're prevalent in mining operations, where mechanical stress from machinery and potential fire risks demand robust solutions. They're also used in power stations, industrial plants, and infrastructure like railways and hospitals, where LSZH properties mitigate risks to life and equipment.

For instance, in underground mining, these cables power pumps and conveyors, buried directly in trenches for cost-effective deployment. In urban settings, they facilitate street lighting and substation connections, resisting environmental factors like moisture and abrasion.

Advantages and Comparative Analysis

Compared to non-armoured cables, these offer superior mechanical protection via AWA, resisting impacts, rodents, and crushing—extending lifespan in harsh conditions. LSZH sheathing provides a safety edge over PVC, emitting less smoke and no halogens, crucial in fire-prone areas.

Single-core vs. multi-core: Singles prevent magnetic heating in AC systems, though they require separate runs for phases. Copper conductors outperform aluminium in conductivity and corrosion resistance, albeit at higher cost.

Environmentally, LSZH reduces toxic waste, aligning with sustainable practices. Economically, their durability lowers maintenance, offsetting initial investment.

Frequently Asked Questions (FAQs)

What is the difference between AWA and SWA armour? AWA (aluminium wire) is used in single-core cables to avoid magnetic fields; SWA (steel wire) suits multi-core for cost-effective protection.

Can these cables be used outdoors? Yes, their UV-resistant LSZH sheath and armour make them suitable for exposed or buried outdoor installations.

Why choose copper over aluminium conductors? Copper offers better conductivity, flexibility, and corrosion resistance, ideal for high-demand applications.

What is the lifespan of these cables? Typically 25-40 years, depending on environment and maintenance, thanks to durable materials.

Are they compliant with South African standards? While based on BS 6724, they align with SANS 1339 for XLPE MV cables in local use.

How do LSZH properties enhance safety? They produce low smoke and no halogens in fires, improving visibility and reducing toxicity.

What sizes are available? From 50 mm² to 1000 mm², as per the parameter table.

Can they handle short circuits? Yes, XLPE insulation withstands up to 250°C briefly.

Are they suitable for mining? Absolutely, their armour protects against mechanical stress in harsh mining environments.

How to select the right cross-section? Based on current load, voltage drop, and installation method—consult BS 6724 tables.

Single-core 1900/3300V armoured cables with circular stranded copper conductors exemplify engineering excellence, blending conductivity, protection, and safety. From their precise construction to versatile applications, they address modern challenges in power transmission. As industries evolve towards greener solutions, these BS 6724-compliant cables remain indispensable, particularly in regions like South Africa with demanding infrastructural needs. By understanding their multifaceted benefits, we appreciate their role in powering a safer, more efficient world.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430