Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Single-core 600/1000V Cables with Circular Stranded Copper Conductor

APPLICATION

These power and control cables are used for electricity supply in low voltage installation system. They are well adapted to underground use in industrial applications where chemical and mechanical protections are needed (refinery areas, chemical plant...).

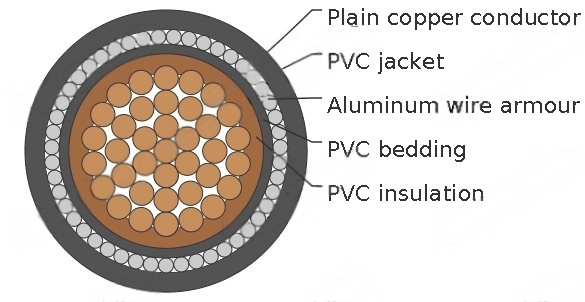

CONSTRUCTION

Conductor | Solid Aluminum or Copper conductor, round stranded or shaped, Class 2 to BS 6460, IEC 60228. |

Insulation | PVC(Polyvinyl Chloride) type TI1 |

Colour Code | 1 Core : Brown |

2 Cores : Brown or Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green-yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Filler(optional) | PVC or Polypropylene yarn |

Binder Tape(optional) | Polyester (Mylar) tape |

Inner Sheath/Bedding | PVC (Polyvinyl Chloride) |

Armour | Single Core : AWA (Aluminum Wire Armour) |

Multi Core : SWA (Steel Wire or Tape Armour) | |

Outer Sheath | PVC(Polyvinyl Chloride), type TM1 |

TECHNICAL INFORMATION

Voltage rating | 600/1000V |

Temperature rating | -20°C to +60°C |

Bending radius | Single core : 10 x overall diameter |

Multicores : 8 x overall diameter | |

Flame retardant | IEC60332 part 1, BS4066 part 1 |

CABLE PARAMETER

Nominal cross-sectional area | Number/wire | Nominal insulation thickness | Nominal beddingthickness | Nominal alum wire armor dia. | Nominal sheath thickness | Approx.overall diameter | Approx.cable weight |

|---|---|---|---|---|---|---|---|

mm² | No./mm | mm | mm | mm | mm | mm | kg/km |

19/1.78 | 1.4 | 0.8 | 1.25 | 1.5 | 19.1 | 820 | |

19/2.14 | 1.4 | 0.8 | 1.25 | 1.6 | 21.1 | 1070 | |

19/2.52 | 1.6 | 0.8 | 1.25 | 1.6 | 23.4 | 1390 | |

37/2.03 | 1.6 | 1.0 | 1.6 | 1.7 | 26.3 | 1600 | |

37/2.25 | 1.8 | 1.0 | 1.6 | 1.7 | 28.3 | 1900 | |

37/2.52 | 2.0 | 1.0 | 1.6 | 1.8 | 30.8 | 2450 | |

61/2.25 | 2.2 | 1.0 | 1.6 | 1.9 | 34.1 | 3100 | |

61/2.52 | 2.4 | 1.0 | 1.6 | 1.9 | 37.0 | 3760 | |

61/2.85 | 2.6 | 1.2 | 2.0 | 2.1 | 42.0 | 4850 | |

61/3.20 | 2.8 | 1.2 | 2.0 | 2.1 | 45.6 | 5930 | |

61/3.65 | 2.8 | 1.2 | 2.0 | 2.2 | 49.7 | 7390 | |

127/2.85 | 2.8 | 1.4 | 2.5 | 2.4 | 55.8 | 9400 | |

127/3.20 | 3.0 | 1.4 | 2.5 | 2.5 | 61.0 | 11430 |

In the heart of South Africa's bustling industrial sectors, from the petrochemical refineries of Sasol in Secunda to the chemical plants dotting the KwaZulu-Natal coastline, reliable electricity supply is the lifeblood of operations. But what happens when power cables must endure underground burial, exposure to corrosive chemicals, and mechanical stresses? Enter the single-core 600/1000V armoured power cable with stranded copper conductors—a stalwart in low voltage installations designed to withstand the rigours of demanding environments. These cables, compliant with South African National Standards (SANS) such as SANS 1507 for extruded dielectric insulated cables and international benchmarks like IEC 60228 for conductors, offer a blend of durability, efficiency, and safety that makes them indispensable.

Understanding the Basics of Single-Core 600/1000V Cables

Single-core cables, as the name suggests, consist of a solitary conductor encased in layers of insulation and protection. Specifically, the 600/1000V rating indicates they are suited for low voltage systems, where 600V is the phase-to-earth voltage and 1000V is phase-to-phase, making them ideal for distribution in industrial settings below 1kV. In South Africa, these align with SANS 10142-1, the wiring code for low voltage installations, which mandates compliance to prevent electrical hazards.

The core is typically made from copper, stranded in a circular formation to Class 2 specifications per IEC 60228 and BS 6460. Stranding involves twisting multiple thinner wires together, enhancing flexibility compared to solid conductors. This is crucial for installation in conduits or trenches where bending is required. Copper's choice stems from its superior electrical conductivity—about 1.7 times that of aluminium—reducing energy losses and heat generation during transmission.

Unlike multi-core cables, which bundle several conductors for three-phase systems, single-core variants are used individually or in groups for high-current applications. For instance, in a three-phase setup, three single-core cables might be laid in trefoil formation to balance magnetic fields and minimise induction effects. Their design promotes better heat dissipation, as there's no mutual heating from adjacent cores, allowing higher current ratings in confined spaces.

In harsh industrial contexts, these cables excel due to their armoured construction. Armouring provides mechanical protection against impacts, rodent damage, and soil pressure in underground burials—common in refineries and chemical plants where direct exposure to hydrocarbons or acids could degrade unarmoured alternatives.

Applications in South African Industry

These cables shine in underground installations where protection is paramount. In refineries, they supply power to pumps and compressors amid volatile chemicals. Chemical plants use them for control systems, leveraging AWA against mechanical damage from heavy machinery.

In mining—South Africa's economic backbone—they power conveyor belts and ventilation in corrosive shafts. Urban infrastructure, like street lighting or substation feeders, also benefits from their durability.

Case in point: Projects under Eskom's transmission upgrades often specify such cables for reliability in high-load scenarios.

Advantages of Stranded Copper in Single-Core Designs

Stranded copper enhances flexibility, crucial for navigating tight spaces. It resists oxidation better than solid counterparts, extending lifespan to 30+ years. In high-frequency applications, skin effect is mitigated, though less relevant at 50Hz.

Single-core setup allows custom phasing, reducing electromagnetic interference. Overall, they offer superior anti-corrosion for outdoor use.

Frequently Asked Questions

What is the difference between AWA and SWA armour? AWA uses aluminium for single-cores to prevent magnetic induction heating, while SWA (steel) is for multi-cores.

Why use stranded conductors over solid? Stranded are more flexible and resistant to breakage from bending or vibration.

Can these cables be used above ground? Yes, but they're optimised for underground with armour protecting against damage.

How do you ground the armour? For single-core AC cables, ground at one end only to avoid circulating currents.

What standards apply in South Africa? Primarily SANS 1507 and SANS 10142-1, harmonised with IEC.

Are they flame retardant? Yes, compliant with IEC 60332-1.

Copper vs aluminium: Which is better? Copper for higher conductivity and durability, though aluminium is lighter and cheaper.

How to cut armoured cable safely? Use a hacksaw or cable cutter, ensuring to deburr edges and avoid damaging insulation.

Single-core 600/1000V copper cables represent engineering excellence, tailored for South Africa's industrial demands. Their robust construction and performance ensure safe, efficient power delivery, underpinning economic growth. As renewable integration accelerates, these cables will remain vital, evolving with standards to meet future challenges.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430