Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Single-core 600/1000V cables with circular stranded copper conductor

APPLICATION

These cables are used for power and control circuits, they can offer excellent protection through the use of a heavy galvanized steel wire armour. The GSWA makes them suitable for use inside and outside buildings or for direct burial in the ground. For installation where fire, smoke emission and toxic fumes create a potential threat to life and equipment.

CONSTRUCTION

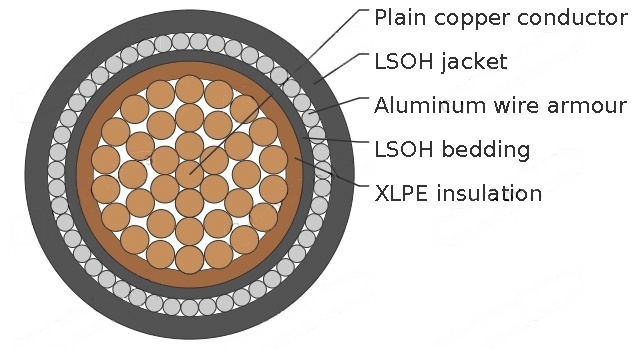

Conductor | Solid Aluminum or Annealed Copper conductor, circular or shaped, Class 2 to BS EN60228. |

Insulation | XLPE (Cross-Linked Polyethylene) Type GP 8 conforming to BS 7655-1.3 or type GP 6 conforming to BS 7655-1.2. |

Colour Code | 1 Core : Brown or Blue |

2 Cores : Brown, Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green/Yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Bedding | The bedding shall consist of an extruded layer of polymeric material consistent with the operating temperature of the cable. |

Armour | Single Core : AWA (Aluminum Wire Armour) |

Multi Core : GSWA (Galvanized Steel Wire Armour) | |

Outer Sheath | LSOH (Low Smoke Zero Halogen),conforming to BS 7655-6.1. |

TECHNICAL INFORMATION

Voltage rating | 600/1000V |

Temperature rating | 0°C to +90°C |

Min. Bending radius | 8 x overall diameter |

Flame retardant | BS EN 60332-1-2 ; BS EN 60332-3-24:2009 |

Halogen free | BS EN 60754-1 |

Smoke density | BS EN 61034-2 |

CABLE PARAMETER

Nominal Cross-sectional Area | Strand Type | Nominal Insulation Thickness | Nominal BeddingThickness | Nominal Alum Wire Armor dia. | Nominal Sheath Thickness | Approx. Overall Diameter | Aprrox. Weight |

|---|---|---|---|---|---|---|---|

mm² | No./mm | mm | mm | mm | mm | mm | kg/km |

19/1.78 | 1.0 | 0.8 | 0.9 | 1.5 | 17.5 | 800 | |

19/2.14 | 1.1 | 0.8 | 1.25 | 1.5 | 20.2 | 990 | |

19/2.52 | 1.1 | 0.8 | 1.25 | 1.6 | 22.3 | 1280 | |

37/2.03 | 1.2 | 0.8 | 1.25 | 1.6 | 24.2 | 1550 | |

37/2.25 | 1.4 | 1 | 1.6 | 1.7 | 27.4 | 1900 | |

37/2.52 | 1.6 | 1 | 1.6 | 1.8 | 30.0 | 2320 | |

61/2.25 | 1.7 | 1 | 1.6 | 1.8 | 32.8 | 2930 | |

61/2.52 | 1.8 | 1 | 1.6 | 1.9 | 35.6 | 3580 | |

61/2.85 | 2.0 | 1.2 | 2.0 | 2.0 | 40.5 | 4600 | |

61/3.20 | 2.2 | 1.2 | 2.0 | 2.1 | 44.2 | 5680 | |

127/2.52 | 2.4 | 1.2 | 2.0 | 2.2 | 48.8 | 7160 | |

127/2.85 | 2.6 | 1.4 | 2.5 | 2.4 | 55.4 | 9315 | |

127/3.20 | 2.8 | 1.4 | 2.5 | 2.5 | 60.6 | 11490 |

Introduction: Powering the Future with Reliable Cables

In a world increasingly dependent on electricity, from bustling Johannesburg offices to remote rural farms in the Free State, the humble cable plays a starring role. But what exactly are single-core 600/1000V cables, and why do they matter? These cables, designed for power and control circuits, form the backbone of many electrical installations. They offer robust protection against mechanical damage and environmental hazards, making them ideal for South Africa's diverse climates and infrastructure needs.

At their core (pun intended), these cables feature a single conductor, typically made from annealed copper in a circular stranded form. This design ensures flexibility and efficiency in transmitting electricity at voltages up to 1000V. With features like cross-linked polyethylene (XLPE) insulation and aluminium wire armour (AWA), they provide safety and durability.

Applications:

Single-core 600/1000V cables aren't confined to labs—they're out in the real world, powering South Africa's economy. Their primary use is in power and control circuits, where they transmit electricity reliably over short to medium distances.

Indoors, they're found in buildings for lighting, machinery, and HVAC systems. The AWA armour protects against accidental damage in walls or conduits. Outdoors, they're buried directly in the ground, resisting soil moisture and mechanical stress—perfect for connecting solar farms in the Northern Cape to the grid.

One key advantage is fire safety. In high-risk areas like mines in Gauteng or petrochemical plants in Secunda, LSOH sheaths reduce smoke density (per BS EN 61034-2) and halogen emissions (BS EN 60754-1), complying with SANS standards. This means less risk to firefighters and equipment during blazes.

For renewable energy, these cables link photovoltaic panels to inverters. Their 90°C rating handles heat from sun-baked installations, and the stranded copper ensures low resistance losses, boosting efficiency. In urban upgrades, like Eskom's grid expansions, they're used for street lighting and substations, where voltage drops must be minimal.

Compared to multi-core cables, single-cores are simpler for high-current applications, avoiding magnetic interference in AC systems. However, they're often paired in installations to form three-phase circuits. In essence, these cables bridge the gap between generation and consumption, supporting South Africa's push towards sustainable energy.

In-Depth Analysis: Advantages, Challenges, and Innovations

Why choose single-core 600/1000V with circular stranded copper? The analysis boils down to efficiency, safety, and longevity.

Efficiency: Stranded copper minimises resistance (e.g., 0.387 Ω/km for 50 mm²), cutting I²R losses. In a 1 km run at 100A, that's savings in kilowatt-hours, aligning with South Africa's energy efficiency goals under the National Energy Regulator (NERSA).

Safety: AWA and LSOH tackle two big risks—mechanical and fire. Studies from the International Electrotechnical Commission (IEC) show armoured cables survive 50% more impacts. In fire tests, LSOH emits 80% less smoke than PVC, potentially saving lives in events like the 2023 Johannesburg building fire.

Challenges: Heavier weights (up to 11 tons/km for large sizes) demand specialised handling. Costlier than basic cables, but lifecycle analysis shows ROI through fewer repairs. Aluminium alternatives are lighter but less conductive, suiting budget projects.

Innovations: Emerging trends include smart cables with embedded sensors for real-time monitoring, integrating with IoT for predictive maintenance. In South Africa, hybrids with fibre optics for data alongside power are gaining traction in mining.

Environmentally, copper is recyclable, and LSOH reduces halogen pollution. As we transition to green energy, these cables support higher ampacities for EV charging stations.

Frequently Asked Questions: Clearing Up Common Queries

What is the difference between single-core and multi-core cables? Single-core have one conductor, ideal for high-current, low-interference setups. Multi-core bundle several, suiting control signals. For power, singles avoid heating from mutual induction.

Can these cables be used underground? Yes, AWA protects against burial stresses. Ensure proper depth (0.6-1m) per SANS 10142-1 to avoid damage.

How do I select the right size? Based on load current, voltage drop (max 5%), and derating factors like ambient temperature. Use tables from BS 7671 or consult an electrician.

Are they suitable for solar installations? Absolutely—their temperature rating and durability handle outdoor exposure. Pair with DC-rated variants for panels.

What maintenance do they need? Visual inspections for damage; test insulation resistance annually. Avoid overloading to prevent overheating.

Why copper over aluminium? Copper offers better conductivity and corrosion resistance, though aluminium is cheaper for long runs.

Do they comply with South African standards? Yes, aligned with SANS 1507 and IEC 60502, ensuring safety and interoperability.

Single-core 600/1000V cables with circular stranded copper conductors are more than wires—they're engineered solutions for a safer, more efficient South Africa. From construction to applications, their design embodies materials science at its best. As we face energy challenges, investing in quality cables ensures reliable power for generations. Next time you flip a switch, remember the tech beneath.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430