Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

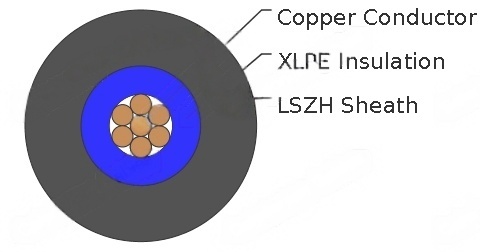

Single Core 600/1000V XLPE Insulation, LSZH Sheath Cables to BS 8573

Application

These XLPE insulated and LSZH sheathed cables are generally used for fixed installation. Suitable for building wiring, especially in areas where smoke and fume emissions may cause a potential threat to life but not for burial in the ground, either directly or in ducts.

Standard

Basic design to BS 8573:2012

Fire Performance

Flame Retardance (Single Vertical Wire Test) | BS EN 60332-1-2:2004 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) | BS EN 60332-3-24:2009 (cat. C) |

Halogen Free | BS EN 50267-2-1 |

Minimum Smoke Emission | BS EN 61034-2 |

Spark Test | BS EN 62230 |

Voltage Rating

600/1000V

Construction

Conductor : Annealed copper conductor, strand according to BS EN 60228 class 2.

Insulation : XLPE type GP8 according to BS 7655-1.3. HEPR type GP6 according to BS 7655-1.2, or crosslinked polyolefin material type EI 5 according to BS EN 50363-5 can be offered as option.

Inner Covering option : The laid up cores may be coverd by an optional extrued inner covering or separating tape. It shall be possible to separate the cores easily.

Outer Sheath : Thermoplastic LSZH type LTS 4 according to BS 7655-6.1.

Outer Sheath option : UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option.

Color Code

Insulation Colour : Brown or blue

Sheath Colour : Black, other colours can be offered upon request.

Physical And Thermal Properties

Maximum temperature range during operation (XLPE) : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius:

Circular copper conductors(up to 25mm²) : 4 x Overall Diameter

Circular copper conductors(above 25mm²) : 6 x Overall Diameter

Shaped copper conductors : 8 x Overall Diameter

Construction Parameters

Conductor | Nominal Insulation Thickness | Nominal Inner Covering Thickness | Nominal Sheath Thickness | |

|---|---|---|---|---|

No. of Cores x Cross Section | Class of Conductor | |||

No. x mm² |

| mm | mm | mm |

2 | 0.7 | 0.4 | 1.4 | |

2 | 0.7 | 0.4 | 1.4 | |

2 | 0.7 | 0.4 | 1.4 | |

2 | 0.7 | 0.4 | 1.4 | |

2 | 0.7 | 0.4 | 1.4 | |

2 | 0.7 | 0.4 | 1.4 | |

2 | 0.9 | 0.4 | 1.4 | |

2 | 0.9 | 0.4 | 1.4 | |

2 | 1.0 | 0.6 | 1.4 | |

2 | 1.1 | 0.6 | 1.4 | |

2 | 1.1 | 0.6 | 1.5 | |

2 | 1.2 | 0.8 | 1.5 | |

2 | 1.4 | 0.8 | 1.6 | |

2 | 1.6 | 0.8 | 1.6 | |

2 | 1.7 | 1.0 | 1.7 | |

2 | 1.8 | 1.0 | 1.8 | |

2 | 2.0 | 1.2 | 1.9 | |

2 | 2.2 | 1.2 | 2.0 | |

2 | 2.4 | 1.4 | 2.2 | |

2 | 2.6 | 1.6 | 2.3 | |

2 | 2.8 | 1.6 | 2.4 | |

Introduction

In an era where building safety and environmental sustainability are paramount, the choice of electrical cables can make a significant difference. Have you ever wondered why certain cables are preferred in high-risk environments like hospitals, schools, and public buildings? Single Core 600/1000V XLPE insulated LSZH sheathed cables, designed to BS 8573:2012, offer a compelling solution. These cables, featuring cross-linked polyethylene (XLPE) insulation and low smoke zero halogen (LSZH) sheathing, are engineered for fixed installations where smoke and fume emissions pose a threat to life.

Fire Performance: A Lifesaving Priority

Fire safety is a critical perspective, especially in South Africa, where annual fire statistics from the Fire Protection Association report thousands of incidents, many in densely populated areas. BS 8573 cables excel here, with flame retardance tested to prevent ignition spread. In a vertical wire test, the cable self-extinguishes, limiting char length.

Reduced fire propagation in bundled setups simulates real-world installations, where cables run in conduits or trays. Category C testing ensures flames do not travel beyond 2.5 metres, crucial in high-rise buildings like those in Johannesburg's CBD.

The LSZH sheath is halogen-free, emitting negligible hydrogen chloride (less than 0.5% per BS EN 50267-2-1), reducing toxicity. Smoke emission is minimised to maintain visibility during evacuations, as per BS EN 61034-2, where transmittance exceeds 60%. This contrasts with PVC cables, which release dense, acidic smoke, exacerbating respiratory issues.

From a safety analysis, these features align with the South African Occupational Health and Safety Act, mandating low-risk materials in workplaces. In scenarios like the 2023 Marshalltown fire, LSZH cables could have reduced smoke-related fatalities, highlighting their preventive role.

Applications and Suitability: Versatile Deployment

Primarily for fixed building wiring, these cables suit areas prone to smoke hazards, such as tunnels, airports, and shopping centres. They are unsuitable for direct burial but excel in ducts or trays.

In South Africa, applications include Cape Town's Table Mountain Cableway, where fire safety is non-negotiable, or Durban's industrial zones requiring oil-resistant variants. Their 600/1000V rating supports residential and commercial low-voltage systems, aligning with Eskom's distribution networks.

From an infrastructural perspective, they facilitate smart city initiatives in eThekwini, providing reliable backbone for IoT integrations without environmental trade-offs.

Advantages Over Traditional Cables: A Comparative Analysis

Compared to PVC-insulated cables, BS 8573 variants offer superior fire safety and lower emissions, though at a higher initial cost. XLPE insulation provides better thermal endurance than rubber, reducing ageing.

Environmentally, LSZH minimises halogen pollution, supporting South Africa's National Environmental Management Act. Economically, while upfront costs are 20-30% higher, longevity and reduced maintenance yield savings. A lifecycle analysis shows payback within 5-7 years through fewer replacements.

Technically, higher ampacity allows smaller cross-sections, optimising material use. Safety-wise, they reduce insurance premiums by mitigating fire risks.

Multiple Perspectives: In-Depth Analysis

Safety Perspective

Safety is paramount, with LSZH reducing toxic fumes by 90% compared to halogenated alternatives. In confined spaces, this preserves escape routes, as evidenced by international studies from the International Electrotechnical Commission (IEC).

Environmental Perspective

Halogen-free composition aligns with global sustainability goals, like the UN's Sustainable Development Goals. In South Africa, where e-waste is a growing issue, recyclable LSZH materials lessen landfill impact.

Economic Perspective

Though premium-priced, these cables lower total ownership costs. A study by the Electrical Contractors' Association estimates 15% savings in high-risk installations due to compliance and durability.

Technical Perspective

XLPE's dielectric constant (around 2.3) ensures low capacitance, ideal for long runs. Construction parameters support scalability, from 1.5 mm² for lighting to 1000 mm² for heavy loads.

FAQs

What is the difference between XLPE and PVC insulation? XLPE offers higher temperature resistance (90°C vs. 70°C) and better mechanical properties, making it suitable for demanding environments.

Are these cables suitable for outdoor use in South Africa? With UV-resistant options, yes, but not for direct burial. They perform well in exposed conduits.

How do LSZH sheaths improve fire safety? They emit low smoke and no halogens, enhancing visibility and reducing toxicity during fires.

What voltage are these cables rated for? 600/1000V, ideal for low-voltage fixed installations.

Can custom colours be requested? Yes, sheaths can be customised beyond standard black.

What is the maximum conductor size available? Up to 1x1000 mm², with corresponding insulation and sheath thicknesses.

How do these cables comply with South African standards? They align with SANS 10142-1 and SANS 10400 for wiring and fire safety.

What options are available for pest resistance? Anti-rodent and anti-termite properties can be added to the sheath.

Is there a warranty or expected lifespan? Typically 25-30 years, depending on installation conditions.

Where can these cables be sourced in South Africa? From certified suppliers like Aberdare Cables or CBI Electric, ensuring BS 8573 compliance.

Single Core XLPE insulated LSZH sheathed cables to BS 8573 represent a pinnacle of electrical engineering, balancing safety, efficiency, and sustainability. As South Africa advances towards safer, greener infrastructure, these cables stand out as an essential component. Whether in bustling metropolises or remote installations, their multifaceted benefits underscore why they are indispensable. By choosing them, we not only comply with standards but also protect lives and the environment.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430