Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Single Core Cables to IEC 60502

Enter Single Core Cables Designed to the IEC 60502 Standard: Robust, Efficient Conductors Engineered for Medium-voltage Power Distribution

Single Core Cables to IEC 60502

Application

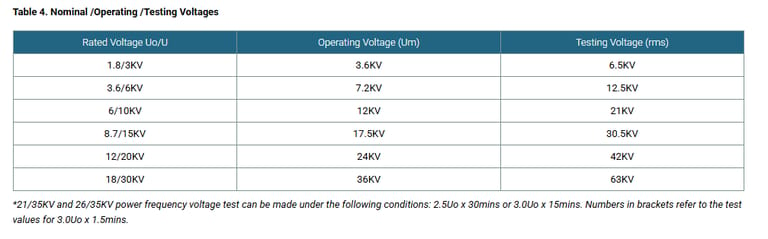

The single core cables are designed for distribution of electrical power with nominal voltage Uo/U ranging from 1.8/3KV to 18/30KV and frequency 50Hz. They are suitable for installation mostly in power supply stations, indoors and in cable ducts, outdoors, underground and in water as well as for installation on cable trays for industries, switchboards and power stations.

Standards

IEC 60502 Part 1(1.8/3KV)

IEC 60502 Part 2(3.6/6KV to 18/30KV)

Construction

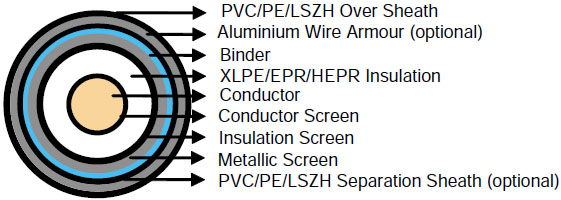

Conductor : Plain annealed copper or aluminium complying with IEC 60228 class 1 or 2.

Conductor Screen : The conductor screen consists of an extruded layer of non metallic, semi-conducting compound firmly bonded to the insulation to exclude all air voids. The conductor screen is not necessary for both PVC and EPR/HEPR insulated 1.8/3KV and 3.6/6KV cables.

Insulation : Insulation is of polyvinyl chloride (PVC) intended for 1.8/3KV and 3.6/6KV cables, cross-linked polyethylene compound (XLPE) or ethylene propylene rubber (EPR/HEPR).

Table 1. Insulation Thickness of XLPE or EPR/HEPR Insulation

Nom. Cross Section Area | Insulation Thickness at Nominal Voltage | |||||||

|---|---|---|---|---|---|---|---|---|

1.8/3KV (Um=3.6KV) | 3.6/6KV (Um=7.2KV) | 6/10KV (Um=12KV) | 8.7/15KV (Um=17.5KV) | 12/20KV (Um=24KV) | 18/30KV (Um=36KV) | |||

mm² | mm | mm | mm | mm | mm | mm | ||

| XLPE/EPR | XLPE | EPR | XLPE/EPR | XLPE/EPR | XLPE/EPR | XLPE/EPR | |

Unscreened | Screened | |||||||

10 | 2.0 | 2.5 | 3.0 | 2.5 | - | - | - | - |

16 | 2.0 | 2.5 | 3.0 | 2.5 | 3.4 | - | - | - |

25 | 2.0 | 2.5 | 3.0 | 2.5 | 3.4 | 4.5 | - | - |

35 | 2.0 | 2.5 | 3.0 | 2.5 | 3.4 | 4.5 | 5.5 | - |

50 – 185 | 2.0 | 2.5 | 3.0 | 2.5 | 3.4 | 4.5 | 5.5 | 8.0 |

240 | 2.0 | 2.6 | 3.0 | 2.6 | 3.4 | 4.5 | 5.5 | 8.0 |

300 | 2.0 | 2.8 | 3.0 | 2.8 | 3.4 | 4.5 | 5.5 | 8.0 |

400 | 2.0 | 3.0 | 3.0 | 3.0 | 3.4 | 4.5 | 5.5 | 8.0 |

500 - 1600 | 2.2-2.8 | 3.2 | 3.2 | 3.2 | 3.4 | 4.5 | 5.5 | 8.0 |

*Insulation Thickness of PVC is 3.4mm (1- 1600mm sq) for 3.6/6KV cables.

Insulaton Screen : The insulation screen consists of an extruded layer of non metallic, semiconducting compound extruded over the insulation. The extruded semi-conducting layer shall consist of bonded or cold strippable semi-conducting compound capable of removal for jointing or terminating. As an option, a semi-conducting tape may be applied over the extruded semi-conducting layer as a bedding for the metallic layer. The minimum thickness is 0.3 mm and the maximum resistivity is 500 Ohm-m at 90°C. The screen is tightly fitted to the insulation to exclude all air voids and can be easily hand stripped on site. The insulation screen is not necessary for both PVC and EPR/HEPR insulated 1.8/3KV and 3.6/6KV cables. The screen may be covered by semi-conductive water blocking swellable tape to ensure longitudinal watertightness.

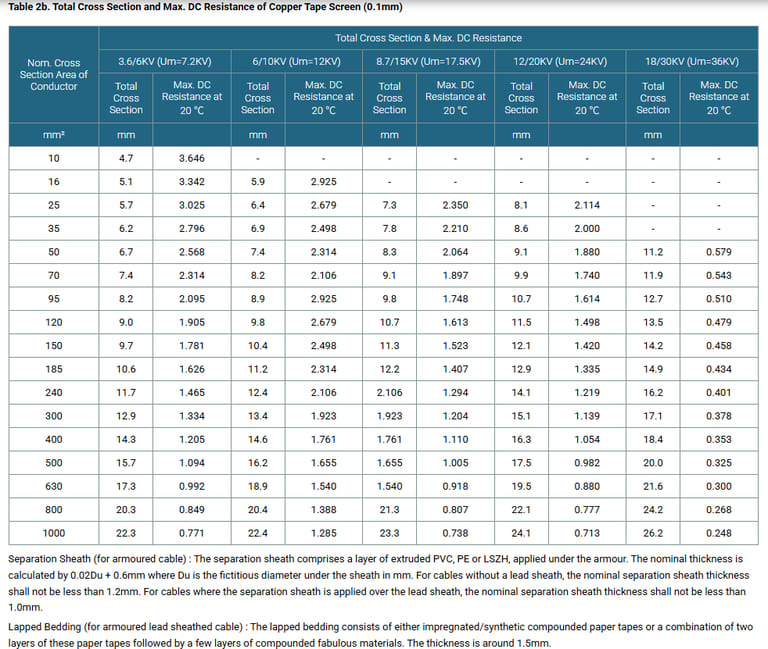

Metallic Layer : The concentric copper screen wire is applied over the insulation, or over the insulation screen or over an inner covering. As an alternative, copper tape(s) with minimum thickness of 0.1mm can be applied with overlap. Total cross section of copper wire screen and copper tape screen layer are shown in Table 2a and 2b.

Table 2a. Total Cross Section and Max. DC Resistance of Copper Wire Screen

Nom. Cross Section Area of Conductor | Total Cross Section | Max. DC Resistance at 20 ℃ | ||||

|---|---|---|---|---|---|---|

3.6/6KV (Um=7.2KV) | 6/10KV (Um=12KV) | 8.7/15KV (Um=17.5KV) | 12/20KV (Um=24KV) | 18/30KV (Um=36KV) | ||

mm² | mm | mm | mm | mm | mm | Ω |

10 | 10 | 10 | 10 | 10 | 10 | 1.075 |

16 | 16 | 16 | 16 | 16 | 16 | 1.075 |

25 | 16 | 16 | 16 | 16 | 16 | 1.075 |

35 | 16 | 16 | 16 | 16 | 16 | 1.075 |

50 | 16 | 16 | 16 | 16 | 16 | 1.075 |

70 | 16 | 16 | 16 | 16 | 16 | 1.075 |

95 | 16 | 16 | 16 | 16 | 16 | 1.075 |

120 | 16 | 16 | 16 | 16 | 16 | 1.075 |

150 | 25 | 25 | 25 | 25 | 25 | 0.688 |

185 | 25 | 25 | 25 | 25 | 25 | 0.688 |

240 | 25 | 25 | 25 | 25 | 25 | 0.688 |

300 | 25 | 25 | 25 | 25 | 25 | 0.688 |

400 | 35 | 35 | 35 | 35 | 35 | 0.491 |

500 | 35 | 35 | 35 | 35 | 35 | 0.491 |

630 | 35 | 35 | 35 | 35 | 35 | 0.491 |

800 | 50 | 50 | 50 | 50 | 50 | 0.344 |

1000 | 50 | 50 | 50 | 50 | 50 | 0.344 |

Understanding Single Core Cables to IEC 60502

Single Core Cables to IEC 60502 are specialized power cables featuring a single conductor core, optimized for medium-voltage applications. Unlike multi-core cables, which bundle several conductors, single-core designs minimize electromagnetic interference and are ideal for high-power transmission over long distances. They operate at a frequency of 50 Hz and are suited for environments requiring durability against mechanical stress, moisture, and temperature fluctuations.

The IEC 60502 standard, established by the International Electrotechnical Commission, ensures these cables meet rigorous global benchmarks for safety and performance. Specifically, IEC 60502 Part 1 covers cables up to 1.8/3 kV, while Part 2 addresses higher voltages from 3.6/6 kV to 18/30 kV. This standard draws from related norms like IEC 60228 for conductors and emphasizes extruded insulation for enhanced reliability.

Benefits of Single Core Cables to IEC 60502

Why choose these cables? Their benefits stem from design ingenuity. First, superior insulation materials like XLPE provide excellent dielectric strength, resisting breakdown and extending lifespan to 30+ years. This reduces replacement costs—a boon in remote setups.

Electromagnetic shielding minimizes induced currents, preventing overheating and interference, especially in single-core setups where phases are separated. Armor options enhance mechanical protection against impacts, rodents, or soil pressure, vital for underground mining.

Energy efficiency is key: low resistance and capacitance mean less power loss, supporting sustainability goals. In South Africa, where electricity costs rose in 2025 despite improved supply, this translates to savings. LSZH sheaths reduce fire risks and toxic emissions, aligning with safety regs.

Versatility allows installation in diverse conditions—wet, dry, or aerial—while compliance with IEC 60502 ensures interoperability globally. Overall, these cables offer reliability, cost-effectiveness, and safety, making them indispensable for high-stakes industries.

Usage Scenarios

Single Core Cables to IEC 60502 shine in power-intensive settings. In power stations, they distribute from transformers to switchgear. Indoors, they're used in ducts for factories; outdoors, on trays for refineries.

Underground, they're buried for urban grids or submerged in water-crossings. In industries, they power heavy machinery; in mining, they supply drills and conveyors deep below.

Their voltage range suits renewable integrations, like connecting solar farms to grids, addressing energy transitions.

Frequently Asked Questions

Q: What's the difference between XLPE and EPR insulation? A: XLPE offers better thermal stability (up to 90°C), while EPR is more flexible and resistant to chemicals, ideal for harsh environments.

Q: Are these cables suitable for underwater use? A: Yes, with proper sheathing and water-blocking, they're designed for submersion.

Q: How do I calculate current rating? A: Use tables based on installation (e.g., buried vs. air) and derate for ambient factors.

Q: What's the lifespan? A: Typically 25-40 years with proper maintenance.

Q: Can they handle South Africa's voltage fluctuations? A: Absolutely, with robust screens and insulation tested to higher voltages.

Single Core Cables to IEC 60502 represent engineering excellence, blending durability, efficiency, and versatility. From technical specs to real-world impacts in South Africa's evolving mining landscape, they empower industries to overcome energy challenges. As trends shift toward sustainability, these cables will play a starring role. For more, consult IEC standards or experts—after all, in power distribution, the right connection changes everything.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430