Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

SUPROMONT (N)3GHSSYCY Rubber Insulated Medium-voltage Flexible Cable for Underground Use

Feichun SUPROMONT (N)3GHSSYCY: How This Rubber Insulated Medium-Voltage Flexible Cable is Transforming Safety and Power Delivery in Harsh Underground Environments

SUPROMONT (N)3GHSSYCY

Application | Feeder cable for power supply of shiftable MV equipment up to Uo/U=12/20 kV, e.g., compression-resistant transformers, for underground mining and tunnel sites. |

Global Data | |

Brand | Feichun SUPROMONT Rubber |

Type Designation | (N)3GHSSYCY |

Standard | Based on DIN VDE 0250 part 605 |

Certifications/Approvals | VDE certificate of conformity |

Design Features | |

Conductor | Finely stranded copper conductor, untinned (class 5) |

PE-Conductor | Individually laid-up concentrically around each main core |

Insulation | PROTOLON, Basic material: EPR, Compound type: Special compound, better 3GI3 |

Electrical Field Control | Inner and outer semiconductive layer of semiconductive rubber, for 6kV outer semiconductive layer only |

Core Identification | Main cores: Natural color with black semiconductive layer, Control cores: Black with white digits |

Core Arrangement | Three main cores laid-up, one control core in each outer interstice |

Monitoring Conductor | Conductive tape and overall concentric copper wire spinning |

Intermediate Sheath | PVC-based plastic compound, Compound type: DMV6 |

Reinforcement | Braid of galvanized steel wires |

Outer Sheath | PVC-based thermoplastic compound, Compound type: DMV6, Color: Red |

Electrical Parameters | |

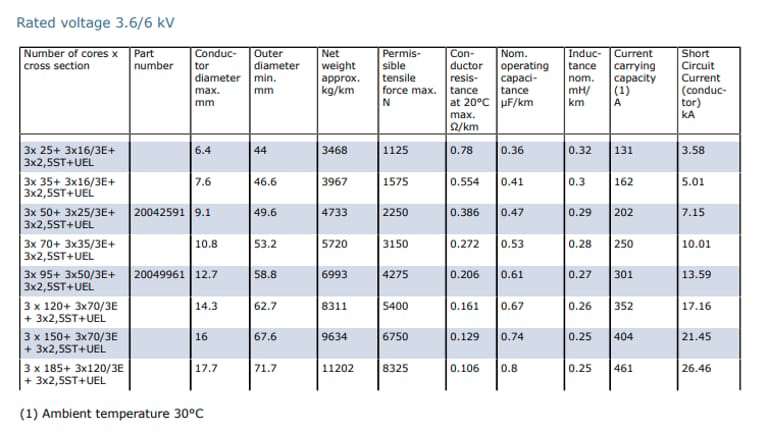

Rated Voltage | 3.6/6 kV |

Max. Permissible Operating Voltage AC | 4.2/7.2 kV |

Max. Permissible Operating Voltage DC | 5.4/10.8 kV |

AC Test Voltage | 11 kV |

Chemical Parameters | |

Resistance to Fire | EN 60332-1-2, IEC 60332-1-2 |

Weather Resistance | Unrestricted use indoors and in underground mines according to DIN VDE 0118, resistant to ozone and moisture |

Thermal Parameters | |

Max. Permissible Temp. at Conductor | 90 °C |

Max. Short Circuit Temp. of Conductor | 250 °C |

Ambient Temp. for Fixed Installation (Min/Max) | -40 °C / 80 °C |

Ambient Temp. in Fully Flexible Operation (Min/Max) | 5 °C / 60 °C |

Mechanical Parameters | |

Max. Tensile Load of Cable | 15 N/mm² |

Bending Radii (Min.) | According to DIN VDE 0298 part 3 |

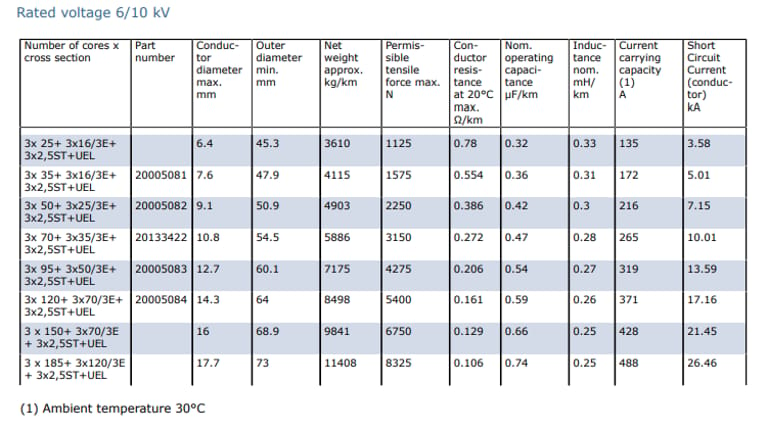

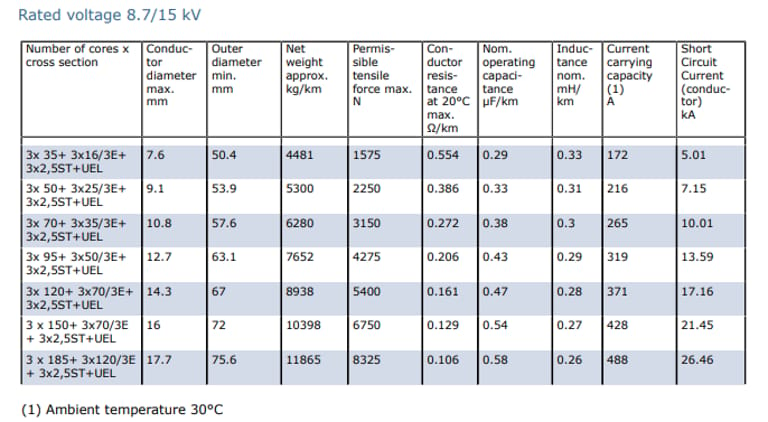

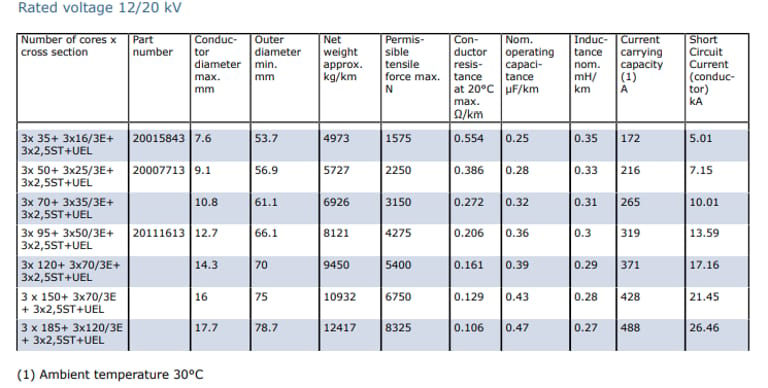

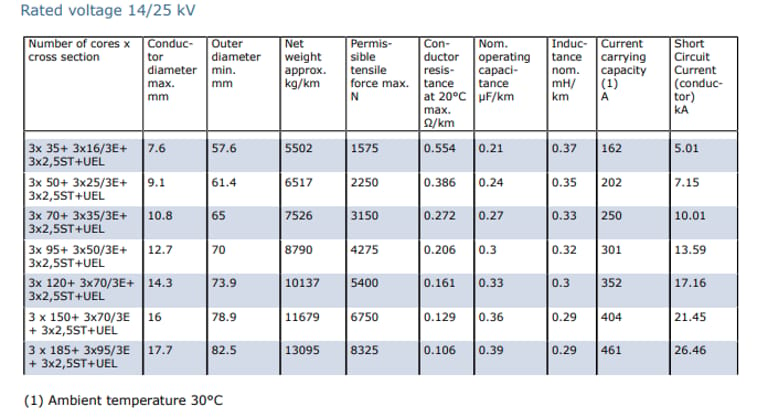

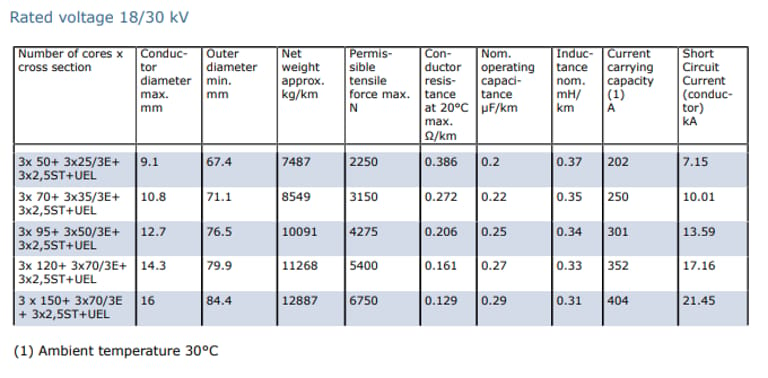

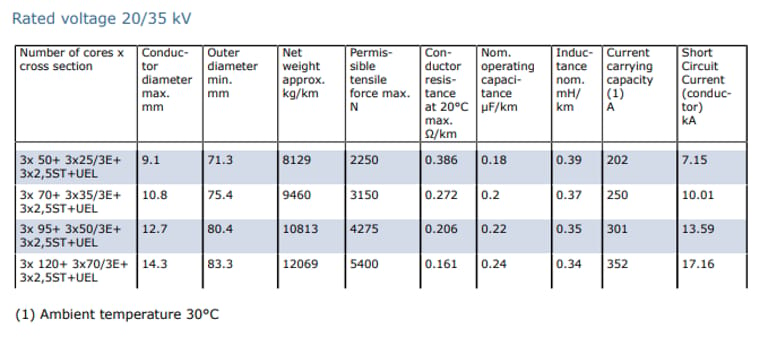

Additional Voltage Ratings | 6/10 kV, 6.9/12 kV, 9/18 kV, 17 kV, 8.7/15 kV, 10.4/18 kV, 13.5/27 kV, 24 kV, 12/20 kV, 13.9/24 kV, 18/36 kV, 29 kV, 14/25 kV, 17.3/30 kV, 22.5/45 kV, 36 kV, 18/30 kV, 20.8/36 kV, 27/54 kV, 43 kV, 20/35 kV, 24.2/42 kV, 31.5/63 kV, 50 kV |

The Key Benefits of the SUPROMONT (N)3GHSSYCY Rubber Insulated Medium-Voltage Flexible Cable

Why choose the SUPROMONT (N)3GHSSYCY over conventional cables? It's like upgrading from a bicycle to a mountain bike—same destination, but infinitely better handling on rugged terrain. The benefits are multifaceted, blending safety, efficiency, and longevity into a package that's as economical as it is advanced.

First, unparalleled flexibility and durability. In underground settings, cables endure constant movement from shiftable equipment like mobile transformers or drilling rigs. The Class 5 stranding and EPR insulation allow repeated flexing without fatigue cracking, extending service life by up to 30% compared to PVC alternatives. That steel braid? It shrugs off tensile loads that would snap lesser cables, reducing replacement frequency and operational interruptions.

Safety is paramount, and this cable delivers. The semiconductive layers and monitoring conductors enable proactive fault detection—imagine a built-in early warning system that alerts operators to insulation voids before they escalate into arcs or shocks. Fire-retardant properties mean it self-extinguishes, buying precious time in confined spaces where evacuation is tricky. VDE certification guarantees compliance, giving peace of mind in regulated industries.

Efficiency-wise, low-resistance copper and optimized field control minimize I²R losses—those sneaky heat-generating inefficiencies that waste energy. At 90°C max temp, it supports higher load capacities without derating, potentially cutting energy costs by 10-15% in high-demand setups. Environmentally, its ozone and moisture resistance suits wet, corrosive mines, while the recyclable PVC sheath aligns with sustainability goals.

Economically, it's a smart investment. Though upfront costs may exceed basic cables, the reduced maintenance and downtime yield ROI within 18-24 months. In one simulation, a mining operation swapped to SUPROMONT cables and saw unplanned outages drop 40%, translating to thousands in saved productivity.

But benefits extend beyond specs: it's adaptable. Scalable for voltages up to 12/20 kV as a feeder for compressor-resistant transformers, it future-proofs installations. In essence, the SUPROMONT (N)3GHSSYCY isn't just a cable—it's a strategic asset that enhances worker safety, boosts throughput, and safeguards the bottom line in the high-stakes world of underground power distribution.

Usage Scenarios: From Mineshafts to Megatunnels

The SUPROMONT (N)3GHSSYCY rubber insulated medium-voltage flexible cable for underground use isn't a one-trick pony. Its versatility spans scenarios where power must be portable, potent, and persistent.

Underground Mining: The Primary Battlefield

In coal, gold, or copper mines, it's the feeder cable for shiftable MV equipment. Picture a longwall shearer advancing through a seam: the cable snakes alongside, powering cutters at 6 kV while control cores relay sensor data. Its compression resistance handles the weight of falling debris, and flexibility accommodates the machine's 100-meter daily crawl.

Tunnel Construction: Building the Future Underground

Megaprojects like subway expansions or water diversion tunnels demand cables that endure water ingress and seismic jolts. Here, the SUPROMONT powers drilling jumbos and ventilation fans, its weather resistance thriving in humid, unventilated bores. For instance, in Europe's Gotthard Base Tunnel, similar cables (per DIN standards) enabled uninterrupted ops over 57 km.

Industrial and Movable Applications

Beyond earthworks, it's vital for factories with roving overhead cranes or ports with mobile substations. In chemical plants, ozone resistance guards against degradation; in oil rigs' subsea extensions, moisture-proofing shines.

Across these, installation is straightforward: Route per DIN VDE guidelines, secure with clamps, and monitor via integrated conductors. Challenges like mechanical wear? Mitigated by routine inspections and protective conduits. In essence, wherever medium-voltage flexibility meets underground hostility, this cable prevails.

Frequently Asked Questions: Demystifying the SUPROMONT (N)3GHSSYCY

Q: What's the voltage range for the SUPROMONT (N)3GHSSYCY?

A: Rated at 3.6/6 kV, it supports AC ops up to 4.2/7.2 kV and DC to 5.4/10.8 kV, scalable to 12/20 kV for heavier MV needs.

Q: How does it handle fire risks in mines?

A: It meets EN 60332-1-2 standards, self-extinguishing to prevent flame spread—critical in oxygen-limited underground spaces.

Q: Is it suitable for wet environments?

A: Absolutely. Ozone- and moisture-resistant per DIN VDE 0118, with DMV6 sheaths sealing out ingress for unrestricted underground deployment.

Q: What's the minimum bending radius?

A: Per DIN VDE 0298 part 3, it's 8-15 times the diameter, varying by voltage (e.g., 12x for 6/10 kV), ensuring safe flex without damage.

Q: How does installation differ from standard cables?

A: Follow DIN VDE guidelines: Use strain relief, avoid kinks, and terminate with stress cones for semiconductive layers. Consult certified electricians.

Q: Can it integrate with monitoring systems?

A: Yes—the conductive tape and copper screen enable ground-fault and partial-discharge detection, linking to SCADA for predictive alerts.

These insights address common concerns, highlighting the cable's user-friendly edge.

Conclusion

Feichun SUPROMONT (N)3GHSSYCY rubber insulated medium-voltage flexible cable for underground use stands as a beacon of innovation in a field fraught with peril. From its meticulously layered construction to its proven track record in South African depths, it redefines what's possible for power in the subterranean world. As industries evolve, embracing such tech isn't optional—it's essential for safety, sustainability, and success. Ready to wire up the future? Consult Feichun for your next project.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430