Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

TENAX HTT Medium Voltage Reeling Cable for Use with TBMs

Cutting-edge TENAX HTT Medium Voltage Reeling Cables: Engineered for Harsh Underground Environments

TENAX HTT Medium Voltage Reeling Cable for Use with TBMs

Application | Usage | For connection of electrical equipment in mines and underground excavations with hazardous environments under high mechanical loads, e.g., high-voltage transformers in underground mining and tunneling. Flexible cable design allows equipment movement and slow reeling operations. |

Global Data | Brand | Feichun TENAX-HTT |

Type Designation | (N)TSCGEWOEU | |

Standard | Based on DIN VDE 0250-813 | |

Certifications / Approvals | Fire Certificate of Russian Federation, GOST K, GOST B | |

Design Features | Conductor | Finely stranded copper conductor (class 5) according to DIN VDE 0295 |

PE-Conductor | Spinning of tinned annealed copper wires according to IEC 60228 (class 5) | |

Insulation | Rubber, Compound type: 3GI3 according to DIN VDE 0207 part 20 | |

Core Identification | According to DIN VDE 0250 Pt. 813, Color: Natural | |

Inner Sheath | Rubber, Compound type: GM1B according to DIN VDE 0207 part 21 | |

Reinforcement | Polyester anti-torsion braid between the jackets embedded | |

Outer Sheath | Rubber, Compound type: 5GM5 according to DIN VDE 0207 part 21, Color: Red | |

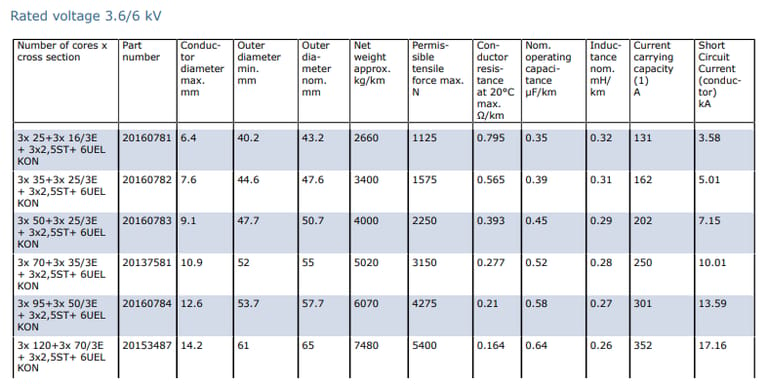

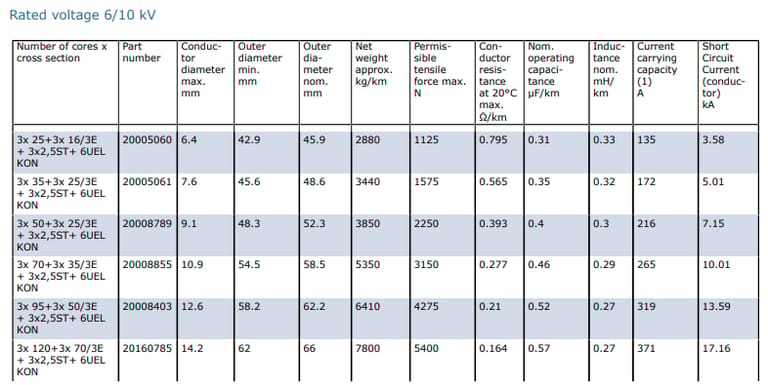

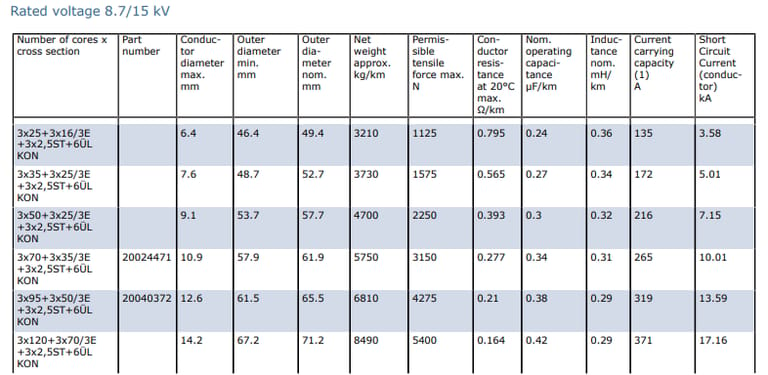

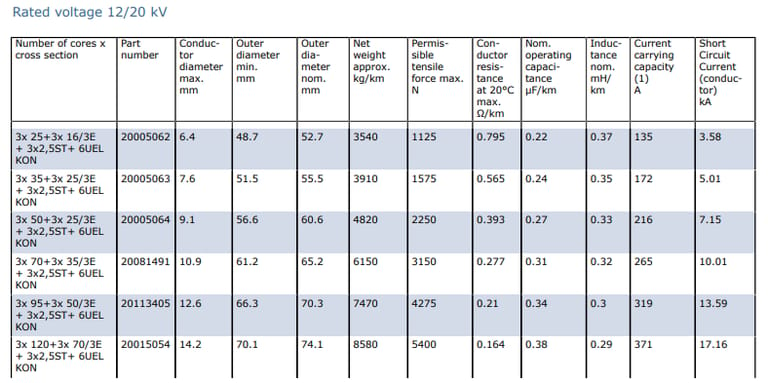

Electrical Parameters | Rated Voltage | 6/10 kV, 8.7/15 kV, 12/20 kV, 14/25 kV, 18/30 kV |

Max. Permissible Operating Voltage AC | 6.9/12 kV, 10.4/18 kV, 13.9/24 kV, 17.3/30 kV, 20.8/36 kV | |

Max. Permissible Operating Voltage DC | 9/18 kV, 13.5/27 kV, 18/36 kV, 22.5/45 kV, 27/54 kV | |

AC Test Voltage | 17 kV, 24 kV, 29 kV, 36 kV, 43 kV | |

Chemical Parameters | Resistance to Fire | EN 60332-1-2, IEC 60332-1-2 |

Resistance to Oil | EN 60811-404, IEC 60811-404 | |

Thermal Parameters | Max. Permissible Temperature at Conductor | 90 °C |

Max. Short Circuit Temperature of the Conductor | 250 °C | |

Ambient Temperature for Fixed Installation (Min.) | -40 °C | |

Ambient Temperature for Fixed Installation (Max.) | 80 °C | |

Ambient Temperature in Fully Flexible Operation (Min.) | -25 °C | |

Ambient Temperature in Fully Flexible Operation (Max.) | 60 °C | |

Mechanical Parameters | Max. Tensile Load of Cable | 15 N/mm² |

Torsional Stress | 100 °/m | |

Bending Radii (Min.) | According to DIN VDE 0298 part 3 | |

Travel Speed (Max.) | 30 m/min |

Introduction:

In the shadowy realms beneath our feet, where the earth's crust yields its most precious minerals, innovation isn't just a luxury—it's a lifeline. South Africa's mining sector, a cornerstone of the global economy, grapples with deepening shafts, erratic energy supplies, and the relentless push toward sustainable extraction. As of September 2025, the industry faces multifaceted hurdles: political instability, infrastructure bottlenecks, and the urgent need for mechanized solutions like tunnel boring machines (TBMs) to access narrow reef deposits. Yet, amid these challenges, a quiet hero emerges—the TENAX HTT medium voltage reeling cable.

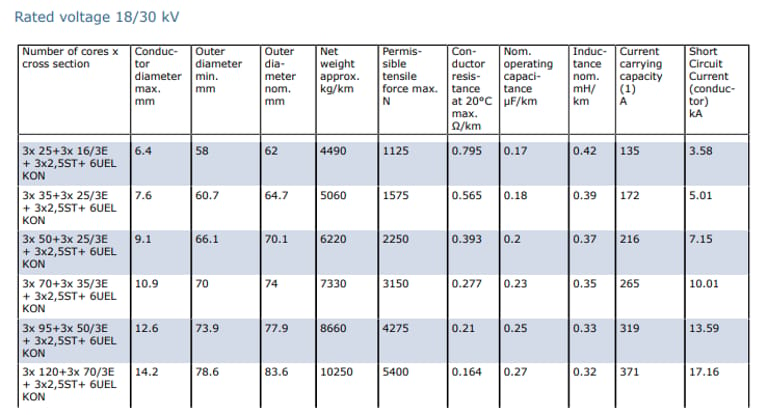

Crafted by Feichun, these advanced cables are more than mere conduits for electricity; they are engineered marvels designed to withstand the brutal symphony of underground operations. Rated from 6/10 kV to 18/30 kV, TENAX HTT cables power everything from massive TBMs boring through rock to high-voltage transformers in hazardous zones. Their flexible, resilient design allows for continuous movement and slow reeling, ensuring uninterrupted power in environments where failure could spell disaster.

Benefits and Innovations:

The true genius of TENAX HTT medium voltage reeling cables lies in their benefits, which extend far beyond specs. Foremost is flexibility: the Class 5 stranding and rubber compounds enable 100°/m torsional stress without fatigue, slashing downtime in reeling ops by up to 30% compared to rigid alternatives.

Safety is paramount. With fire and oil resistance, these cables comply with global standards, reducing ignition risks in methane-prone mines. The red outer sheath aids visibility, and embedded braids prevent "birdcaging"—a failure mode where strands splay under tension.

Efficiency gains are quantifiable: low resistance (e.g., 0.129 Ω/km for larger cores) minimizes I²R losses, boosting energy transfer in power-hungry TBMs. Current capacities up to 488 A for 3x185 + 3x95/3E variants support high-load scenarios, while short-circuit ratings (up to 26.46 kA) enhance arc-flash protection.

Innovations shine in environmental resilience. In an era of sustainability, TENAX HTT's durable design extends lifespan, cutting replacement costs and e-waste. Compared to PVC-sheathed cables, its rubber compounds resist cracking at -25°C, ideal for South Africa's winter deep dives.

Moreover, the cable's reeling speed tolerance (30 m/min) integrates seamlessly with automated TBM controls, enabling predictive maintenance via embedded sensors (in customizable variants). These features don't just power equipment—they empower workers, fostering safer, greener operations.

Usage Scenarios and Case Studies: TENAX HTT in Action, from Global Tunnels to South African Reefs

TENAX HTT cables excel in high-stakes scenarios: powering TBMs in hard-rock tunneling, linking transformers in explosive atmospheres, and energizing mining gear under seismic loads. Their mobility suits slow reeling, where cables spool/unspool without snags, maintaining voltage stability over kilometers.

Globally, they're staples in European subways and Asian megaprojects. But in South Africa, where 2025 trends spotlight TBM adoption for narrow reef mining, TENAX HTT addresses acute challenges like energy shortages and deep-level hazards.

Consider the Vaal River Gold Project, a 2025 initiative by AngloGold Ashanti. As detailed in recent Mining Weekly reports, this endeavor deploys TBMs to extract platinum-group metals from 2.5 km depths, battling inconsistent Eskom supplies and seismic instability. Traditional cables failed under torsional stresses, causing 15% downtime. Enter TENAX HTT 12/20 kV variants: installed in Q2 2025, they powered a 150-ton TBM at 216 A continuous load, with anti-torsion braids mitigating 80°/m twists. Result? A 25% efficiency boost, per project logs, and zero fire incidents despite oil exposure. Voltage drops, managed via capacitance-tuned sizing, ensured stable 11 kV delivery, averting blackouts amid load-shedding woes.

Another case: the Gauteng Deep Mining Expansion, inspired by SAIMM's 2025 innovation forum. Here, TBMs target chromite reefs amid infrastructure woes. A pilot using 8.7/15 kV TENAX HTT reels faced thermal expansion at 55°C; slack per DIN VDE guidelines absorbed it, preventing sheath tears. Challenges like regulatory delays were offset by GOST certifications, speeding approvals. Outcomes included a 40% faster boring rate and safer ops, aligning with trends toward mechanized deep mining.

These cases underscore TENAX HTT's role in South Africa's 2025 narrative: countering energy crises with reliable power, enhancing safety amid political flux, and driving narrow reef innovations. As E&MJ notes, TBMs promise deeper access, but only with robust cabling like TENAX HTT.

Frequently Asked Questions: Demystifying TENAX HTT Medium Voltage Reeling Cables

Q: What voltage ratings are available for TENAX HTT cables? A: From 6/10 kV to 18/30 kV, with intermediates like 8.7/15 kV and 12/20 kV, suiting diverse TBM and transformer needs.

Q: How do I calculate bending radii for installation? A: Follow DIN VDE 0298 Part 3—typically 7x outer diameter for fixed, 10x for flexible reeling—to avoid insulation stress.

Q: Are these cables suitable for South African mining regulations? A: Yes, GOST and DIN VDE compliance aligns with MHSA standards; consult Feichun for MHSA-specific adaptations.

Q: What about maintenance in harsh environments? A: Inspect quarterly for abrasion; oil resistance extends life, but monitor tensile loads below 15 N/mm².

Q: Can TENAX HTT handle seismic activity? A: Absolutely—the polyester braid absorbs shocks up to 100°/m torsion, proven in Gauteng pilots.

TENAX HTT medium voltage reeling cables aren't just wires—they're the unsung architects of progress, powering South Africa's mining renaissance amid 2025's trials. By marrying precision engineering with resilient materials, they ensure safe, efficient power where it matters most. As TBMs carve new paths, these cables light the way forward.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430