Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Thermosetting insulated, single-core, sheathed cables

APPLICATION AND DESCRIPTION

These single core cables are designed for fixed wiring purposes in domestic and industrial power/lighting applications. Can be used in trunking or conduit, or may be surface mounted when used for earthing. and generally in areas (such as public and government buildings) where smoke and toxic fumes may cause a threat to life and equipment. The cables produce no corrosive gasses when burnt which is particularly important where electronic equipment is installed.

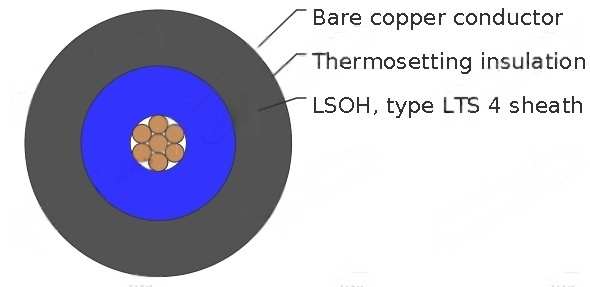

CABLE CONSTRUCTION

Fine bare copper strands

Strands to IEC 60228 Cl-1 or 2

Thermosetting core insulation type EI5 or GP 8

Core identification : brown or blue

LSOH sheath, type LTS 4

TECHNICAL CHARACTERISTICS

Working voltage : 450/750v

Test voltage : 2500 volts

Flexing bending radius : 15 x Ø

Static bending radius : 10 x Ø

Flexing temperature : -25º C to +90º C

Short circuit temperature : +250º C

Flame retardant : IEC 60332.1

Insulation resistance : 10 MΩ x km

Smoke density acc. to EN 50268 / IEC 61034

Corrosiveness of combustion gases acc. to EN 50267-2-2, IEC 60754-2

Flame test : flame-retardant acc. to EN 50265-2-1, IEC 60332.1

CABLE PARAMETER

AWG | No. Of Cores × Nominal Cross Sectional Area | Nominal Thickness Of Insulation | Nominal Thickness Of Sheath | Nominal Overall Diameter | Nominal Weight | Minimum Insulation Resistance At 90 °C |

|---|---|---|---|---|---|---|

# × mm² | mm | mm | mm | kg/km | mΩ·km | |

17 | 0.7 | 0.8 | 3.9-4.8 | 26 | 0.011 | |

17(7/26) | 0.7 | 0.8 | 4-4.9 | 31 | 0.011 | |

16 | 0.7 | 0.8 | 4.2-5 | 34 | 0.011 | |

16(7/24) | 0.7 | 0.8 | 4.3-5.2 | 39 | 0.010 | |

14 | 0.7 | 0.8 | 4.6-5.5 | 46 | 0.0092 | |

14(7/22) | 0.7 | 0.8 | 4.7-5.6 | 51 | 0.0084 | |

12 | 0.7 | 0.8 | 5.0-6.0 | 65 | 0.0077 | |

12(7/20) | 0.7 | 0.9 | 5.3-6.4 | 72 | 0.0070 | |

10 | 0.7 | 0.9 | 5.7-6.8 | 90 | 0.0065 | |

10(7/18) | 0.7 | 0.9 | 5.9-7.1 | 99 | 0.0059 | |

8(7/16) | 0.7 | 0.9 | 6.7-8.1 | 141 | 0.0047 | |

6(7/14) | 0.7 | 0.9 | 7.6-9.2 | 205 | 0.0039 | |

4(7/12) | 0.9 | 1.0 | 9.4-11.4 | 318 | 0.0039 | |

2(7/10) | 0.9 | 1.1 | 10.6-12.8 | 482 | 0.0034 |

Introduction

In an era where building safety is paramount, especially in densely populated urban areas like those in South Africa, the choice of electrical wiring can mean the difference between life and death during emergencies. Have you ever wondered why certain cables are preferred in public buildings, hospitals, and industrial facilities? Thermosetting insulated single-core sheathed cables, often featuring Low Smoke Zero Halogen (LSOH) sheaths, are designed specifically for fixed wiring applications in domestic and industrial power and lighting systems. These cables are engineered to provide reliable performance while prioritising safety, particularly in environments where smoke and toxic fumes could pose significant risks to human life and sensitive equipment.

According to industry standards, these single-core cables are constructed with fine bare copper strands compliant with IEC 60228 Class 1 or 2, thermosetting core insulation such as EI5 or GP 8, and an LSOH sheath of type LTS 4. The core identification is typically brown or blue, making installation straightforward. What sets them apart is their ability to produce no corrosive gases when burnt, which is crucial in areas with electronic equipment. In South Africa, where regulations align with international norms like those from the International Electrotechnical Commission (IEC), these cables are increasingly adopted to comply with fire safety requirements in government and public buildings.

In-Depth Analysis: Multiple Perspectives

Electrical Performance

Electrically, these cables excel due to their low resistance and high insulation integrity. The copper conductors ensure minimal power loss, with insulation resistance maintaining efficiency even at 90°C. Compared to thermoplastic options, thermosetting insulation handles higher temperatures without melting, as noted in Anixter's comparisons, making them suitable for overload-prone circuits in industrial lighting.

Mechanical Properties

Mechanically, the stranded design (Class 2) offers flexibility for bending, while the sheath provides abrasion resistance. The bending radii support installation in trunking or conduits, common in South African buildings. Their weight and diameter facilitate handling, reducing labour costs.

Safety and Fire Resistance

Safety is the standout feature. LSOH sheaths minimise smoke and halogens, complying with IEC 60332 for flame retardancy and EN 50267 for low corrosivity. In fires, this reduces toxicity, aiding evacuation in public buildings like schools or malls. Studies from Lapp Group emphasise functional retention during fires, protecting lives and property.

Environmental Impact

Environmentally, halogen-free composition reduces pollution. No corrosive gases mean less damage to ecosystems post-fire, aligning with green building standards in South Africa. As per AGC Lighting, they contribute to sustainability by being less toxic.

Applications and Economic Perspectives

Applications include domestic wiring, industrial power, and earthing in government buildings. In South Africa, they're used in hospitals where equipment sensitivity is high. Economically, their durability lowers replacement frequency, offering long-term savings despite initial costs.

Frequently Asked Questions (FAQs)

What is the difference between LSOH and LSZH cables? LSOH and LSZH are interchangeable terms for Low Smoke Zero Halogen cables, which emit minimal smoke and no halogens in fires, as explained by Comms Express.

Why use single-core cables for fixed wiring? They provide a single electrical path, ideal for high-current transmission in buildings, with easy termination, per Prysmian.

Are these cables suitable for outdoor use? While primarily for indoor fixed wiring, their temperature range (-25°C to +90°C) allows limited outdoor applications in protected conduits.

How do thermosetting cables compare to thermoplastic in fire safety? Thermosets don't melt, maintaining structure longer, unlike thermoplastics, enhancing safety (Anixter).

What standards ensure their safety? IEC 60332 for flame retardancy, IEC 61034 for smoke density, and IEC 60754-2 for halogen content.

Can they be used in South African public buildings? Yes, they align with SANS and IEC standards, recommended for areas with high occupancy.

Thermosetting insulated single-core sheathed cables represent a pinnacle of safety and reliability in electrical wiring. Their LSOH properties, robust construction, and compliance with global standards make them indispensable in modern buildings, particularly where human safety is at stake. As South Africa continues to urbanise, adopting these cables ensures resilient infrastructure. Ultimately, investing in such technology not only meets regulatory demands but safeguards lives and assets for the future.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430