Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

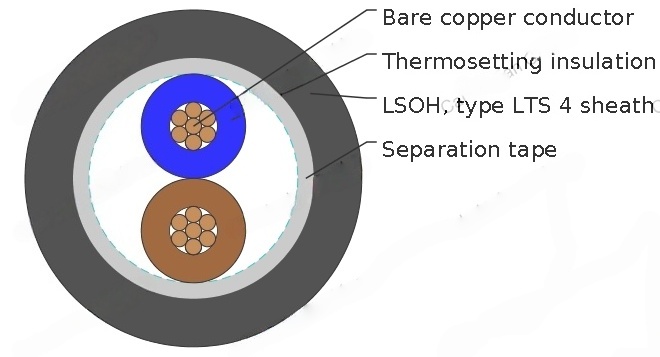

Thermosetting insulated, twin, 3-core, 4-core and 5-core circular sheathed cables

APPLICATION AND DESCRIPTION

These cables are designed for fixed wiring purposes in domestic and industrial power/lighting applications. Can be used in trunking or conduit, or may be surface mounted when used for earthing. and generally in areas (such as public and government buildings) where smoke and toxic fumes may cause a threat to life and equipment. The cables produce no corrosive gasses when burnt which is particularly important where electronic equipment is installed.

CABLE CONSTRUCTION

Fine bare copper strands

Strands to IEC 60228 Cl-1 or 2

Thermosetting core insulation type EI5 or GP 8

The cores shall be twisted together. A centre filler may be used.

The twisted core shall be covered by an extruded inner covering or separating tape

LSOH sheath, type LTS 4

INSULATION COLOUR

Twin : brown and blue

3-core : brown, black and grey

4-core : blue, brown, black and grey

5-core : green/yellow, blue, brown, black and grey

TECHNICAL CHARACTERISTICS

Working voltage : 450/750v

Flexing bending radius : 15 x Ø

Test voltage : 2500 volt

Static bending radius : 10 x Ø

Flexing temperature : -25º C to +90º C

Short circuit temperatur : +250º C

Flame retardant : IEC 60332.1

Insulation resistance : 10 MΩ x km

Smoke density acc. to EN 50268 / IEC 61034

Corrosiveness of combustion gases acc. to EN 50267-2-2, IEC 60754-2

Flame test : flame-retardant acc. to EN 50265-2-1, IEC 60332.1

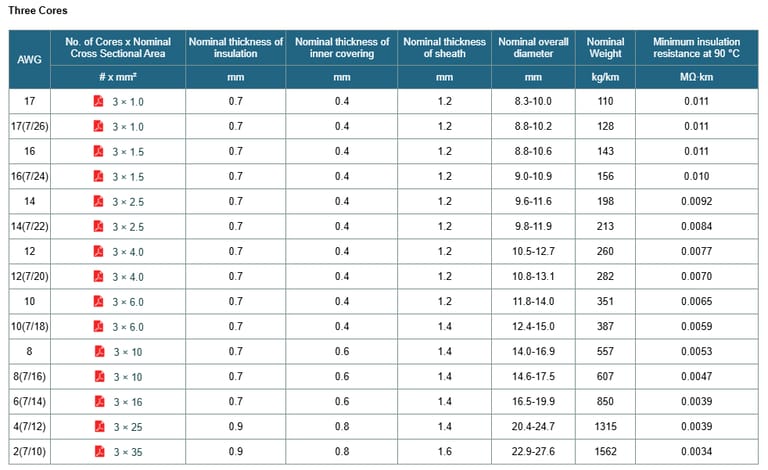

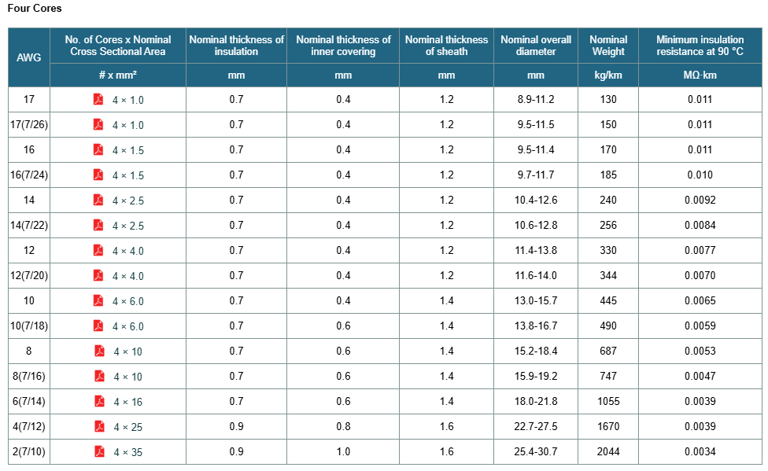

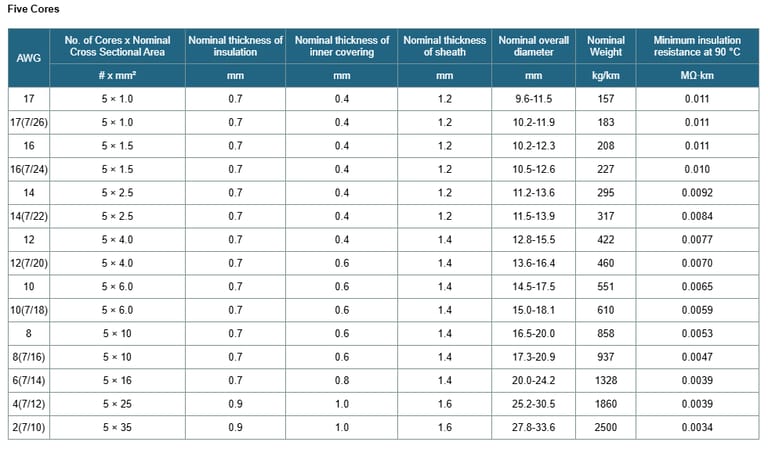

CABLE PARAMETER

Two Cores

AWG | No. of Cores x Nominal Cross Sectional Area | Nominal thickness of insulation | Nominal thickness of inner covering | Nominal thickness of sheath | Nominal overall diameter | Nominal Weight | Minimum insulation resistance at 90 °C |

|---|---|---|---|---|---|---|---|

# x mm² | mm | mm | mm | mm | kg/km | MΩ·km | |

17 | 0.7 | 0.4 | 1.2 | 7.9-9.5 | 94 | 0.011 | |

17(7/26) | 0.7 | 0.4 | 1.2 | 8.1-9.7 | 110 | 0.011 | |

16 | 0.7 | 0.4 | 1.2 | 8.4-10.1 | 121 | 0.011 | |

16(7/24) | 0.7 | 0.4 | 1.2 | 8.5-10.3 | 132 | 0.010 | |

14 | 0.7 | 0.4 | 1.2 | 9.1-11.0 | 165 | 0.0092 | |

14(7/22) | 0.7 | 0.4 | 1.2 | 9.3-11.3 | 178 | 0.0084 | |

12 | 0.7 | 0.4 | 1.2 | 10.0-12.1 | 212 | 0.0077 | |

12(7/20) | 0.7 | 0.4 | 1.2 | 10.3-12.4 | 232 | 0.0070 | |

10 | 0.7 | 0.4 | 1.2 | 10.9-13.2 | 272 | 0.0065 | |

10(7/18) | 0.7 | 0.4 | 1.2 | 11.3-13.7 | 302 | 0.0059 | |

8 | 0.7 | 0.4 | 1.4 | 12.9-15.5 | 446 | 0.0053 | |

8(7/16) | 0.7 | 0.6 | 1.4 | 13.8-16.7 | 490 | 0.0047 | |

6(7/14) | 0.7 | 0.6 | 1.4 | 15.6-18.8 | 674 | 0.0039 | |

4(7/12) | 0.9 | 0.8 | 1.4 | 19.2-23.2 | 1040 | 0.0039 | |

2(7/10) | 0.9 | 0.8 | 1.6 | 21.5-26.0 | 1130 | 0.0034 |

Applications and Benefits: From Homes to High-Rises

These thermosetting insulated cables are tailored for fixed wiring in domestic and industrial power/lighting setups. In homes, twin-core variants handle basic circuits, while 3-core or 4-core options power appliances in kitchens or workshops. Industrially, 5-core cables with earthing are preferred for machinery requiring grounded protection.

Their LSOH properties shine in public spaces like government buildings, schools, and hospitals, where fire safety is critical. Unlike halogenated cables, they don't emit toxic fumes, aiding compliance with occupational health laws in South Africa.

Benefits include enhanced durability against heat and chemicals, lower maintenance costs, and environmental sustainability. From a cost-benefit analysis, though initially pricier than PVC cables, their longevity and safety reduce long-term risks, such as fire damage claims.

In multi-perspective analysis, applications extend to renewable energy setups, like solar inverters, where thermosetting insulation withstands outdoor exposures. Safety benefits are quantifiable: studies show LSOH cables can reduce smoke opacity by up to 70%, improving visibility during evacuations.

In-Depth Analysis: Multi-Faceted Perspectives

Electrical Performance

Electrically, these cables excel due to copper's low resistivity (about 1.68 × 10^-8 Ω·m), enabling high current-carrying capacity. For instance, a 2 × 6.0 mm² twin-core cable can handle loads up to 40A safely. The thermosetting insulation's dielectric strength prevents breakdowns, with minimum resistance at 90°C ranging from 0.0034 to 0.011 MΩ·km across sizes.

Compared to single-core cables, multi-core designs offer balanced phase distribution in 3-core or 4-core setups, minimising electromagnetic interference in sensitive electronics.

Mechanical Properties

Mechanically, the circular sheath provides uniform stress distribution, with nominal thicknesses from 1.2 to 1.6 mm ensuring abrasion resistance. Stranded configurations (e.g., 7/20 for 4.0 mm²) enhance flexibility, reducing installation fatigue.

In harsh environments, like South African mines, the -25°C to +90°C range prevents brittleness, while short-circuit tolerance protects against surges.

Safety and Environmental Impact

Safety is paramount: LSOH sheaths comply with IEC 60754-2, emitting no halogens, thus avoiding corrosion in fire scenarios. This is crucial in densely populated areas, where traditional cables could exacerbate acid rain-like effects indoors.

Environmentally, these cables support sustainable practices by being recyclable and low-emission, aligning with South Africa's National Environmental Management Act.

Comparative Analysis

Versus PVC cables, thermosetting types offer better heat resistance but at higher cost. Twin-cores suit simple circuits, while 5-cores provide comprehensive earthing for complex systems. In global contexts, they meet EU RoHS directives, making them export-friendly for South African manufacturers.

Frequently Asked Questions (FAQs)

What is the main advantage of LSOH sheaths in these cables? LSOH sheaths minimise smoke and eliminate halogen emissions during fires, enhancing safety in enclosed spaces like buildings.

How do I choose between twin, 3-core, 4-core, or 5-core cables? Twin for basic single-phase; 3-core for three-phase without neutral; 4-core with neutral; 5-core for earthed systems in industrial use.

Are these cables suitable for outdoor installations in South Africa? Yes, their temperature range and mechanical strength make them ideal, though UV protection may be needed for direct sunlight.

What standards do these cables comply with? Primarily IEC 60332.1 for flame retardancy, EN 50268 for smoke, and IEC 60228 for conductors.

How does thermosetting insulation differ from thermoplastic? Thermosetting doesn't melt under heat, maintaining shape during overloads, unlike thermoplastic which can deform.

Thermosetting insulated multi-core cables represent a blend of innovation and safety, addressing the demands of modern electrical systems. From their robust construction to superior technical traits, they offer unparalleled protection against fire hazards while ensuring efficient performance. In South Africa, adopting these cables not only complies with evolving regulations but also promotes sustainable development. As we question their essentiality, the answer lies in their ability to safeguard lives and infrastructure—making them indispensable for the future of electrical wiring.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430