Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Three-core 1900/3300 V cables with stranded copper conductors

APPLICATION

These cables are used for power and control circuits, they can offer excellent protection through the use of a heavy galvanized steel wire armour, so they are well adapted to underground use in industrial applications, in moist areas.

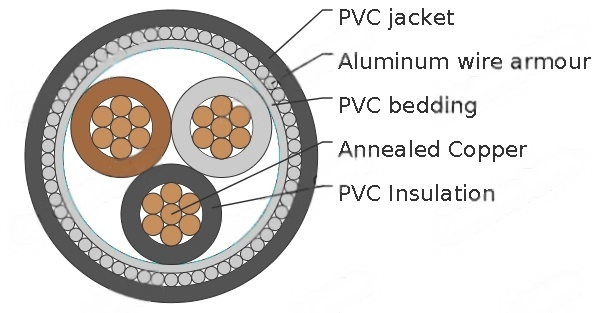

CONSTRUCTION

Conductor | Solid Aluminum or Copper conductor, round stranded or shaped, Class 2 to BS 6460, IEC 60228. |

Insulation | PVC(Polyvinyl Chloride) type TI1 |

Colour Code | 1 Core : Brown |

2 Cores : Brown or Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green-yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Filler(optional) | PVC or Polypropylene yarn |

Binder Tape(optional) | Polyester (Mylar) tape |

Inner Sheath/Bedding | PVC (Polyvinyl Chloride) |

Armour | Single Core : AWA (Aluminum WireArmour) |

Multi Core : SWA (Steel Wire or Tape Armour) | |

Outer Sheath | PVC(Polyvinyl Chloride), type TM1 |

TECHNICAL INFORMATION

Voltage rating | 1900/3300V |

Temperature rating | -20°C to +60°C |

Bending radius | Single core : 10 x overall diameter |

Multicores : 8 x overall diameter | |

Flame retardant | IEC60332 part 1, BS4066 part 1 |

CABLE PARAMETER

Nominal cross-sectional area | Number/wire | Nominal insulation thickness | Nominal bedding thickness | Nominal wire armor dia. | Nominal sheath thickness | Approx.overall diameter | Approx.cable weight |

|---|---|---|---|---|---|---|---|

mm² | No./mm | mm | mm | mm | mm | mm | kg/mm |

7/1.70 | 2.2 | 1.0 | 1.6 | 1.8 | 30.3 | 1700 | |

7/2.14 | 2.2 | 1.0 | 1.6 | 1.8 | 33.1 | 2085 | |

19/1.53 | 2.2 | 1.0 | 1.6 | 1.9 | 35.8 | 2405 | |

19/1.53 | 2.2 | 1.0 | 1.6 | 1.9 | 32.1 | 2405 | |

19/1.78 | 2.2 | 1.2 | 2.0 | 2.0 | 35.6 | 3160 | |

19/2.14 | 2.2 | 1.2 | 2.0 | 2.1 | 38.9 | 3925 | |

19/2.52 | 2.2 | 1.2 | 2.0 | 2.2 | 42.3 | 4860 | |

37/2.03 | 2.2 | 1.4 | 2.5 | 2.3 | 46.6 | 6205 | |

37/2.25 | 2.2 | 1.4 | 2.5 | 2.4 | 49.4 | 7175 | |

37/2.52 | 2.2 | 1.4 | 2.5 | 2.5 | 52.8 | 8320 | |

61/2.25 | 2.2 | 1.6 | 2.5 | 2.6 | 57.8 | 10395 | |

61/2.52 | 2.4 | 1.6 | 2.5 | 2.8 | 63.2 | 12575 | |

61/2.85 | 2.6 | 1.6 | 2.5 | 3.0 | 69.6 | 15325 |

Introduction

In the realm of electrical engineering, the question arises: Are three-core 1900/3300 V cables the backbone of reliable industrial power supply? These cables, designed for medium-voltage applications, play a pivotal role in ensuring efficient power transmission and control in demanding environments. With their robust construction featuring stranded copper conductors, polyvinyl chloride (PVC) insulation, and steel wire armour (SWA), they are engineered to withstand the rigours of underground installation and moist conditions.

Applications in Industrial Settings

Three-core 1900/3300 V cables are primarily employed in power and control circuits, offering superior protection against physical and environmental stresses. Their heavy galvanised steel wire armour makes them ideal for underground burial, a common practice in South African industries where surface clutter must be minimised for safety and efficiency. In moist areas, such as coastal regions like Durban or flood-prone mining sites, these cables excel by resisting water ingress and corrosion, ensuring longevity and reliability.

Consider the mining sector, a cornerstone of South Africa's economy. Here, three-core cables with stranded copper conductors facilitate the powering of heavy machinery, conveyor systems, and ventilation equipment. The stranded design enhances flexibility, allowing the cable to navigate tight bends without compromising conductivity. Unlike solid conductors, stranded ones consist of multiple wires twisted together—typically in configurations like 7/1.70 mm for 16 mm² cross-sections—reducing the risk of breakage under vibrational stress from drilling or blasting operations.

In petrochemical refineries, these cables support control circuits for pumps and valves, where precise voltage delivery is crucial. The 1900/3300 V rating accommodates the step-down from higher substation voltages, providing a safe margin for fluctuations. However, common cable issues in such environments include armour corrosion due to chemical exposure. Galvanised steel offers initial protection, but prolonged contact with acidic soils or spills can lead to pitting, weakening the armour and exposing inner layers. To address this, regular inspections and the application of additional protective coatings, such as bituminous compounds, are recommended.

Furthermore, in renewable energy projects like wind farms in the Eastern Cape, these cables connect turbines to substations underground, minimising visual impact and protecting against wildlife interference. The multi-core setup—typically brown, black, and grey for phase identification—ensures balanced three-phase power distribution, reducing harmonic distortions that could affect sensitive electronics.

Addressing Common Cable Issues

Despite their design, three-core 1900/3300 V cables face several issues. Insulation degradation from thermal cycling is prevalent; repeated heating and cooling cause PVC to lose plasticity, leading to cracks. Solutions include using cross-linked polyethylene (XLPE) alternatives in high-heat areas, though PVC remains cost-effective.

Armour corrosion in acidic soils, common in South African mining regions, can be mitigated with cathodic protection or polyethylene outer jackets. Conductor issues like oxidation at joints reduce conductivity; proper crimping and antioxidants prevent this.

Mechanical damage from excavation is another concern; locating cables with tracers and using warning tapes is standard. Electrical faults, such as short circuits, can melt insulation—surge protection devices help.

In humid conditions, moisture ingress via damaged sheaths causes swelling and reduced insulation resistance. Routine megger testing identifies this early.

Finally, ageing leads to embrittlement; lifespan averages 20-30 years, but condition monitoring extends it.

In answering whether three-core 1900/3300 V cables are the backbone of reliable industrial power supply, the evidence is affirmative. Their stranded copper conductors, robust armour, and PVC insulation provide a resilient solution for South Africa's industries. By addressing common issues through proactive maintenance and proper installation, their efficacy is maximised. As the nation advances towards sustainable energy, these cables will remain integral, embodying engineering excellence.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430