Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Three-core 1900/3300V cables with stranded copper conductors

APPLICATION

These cables are used for power and control circuits, they can offer excellent protection through the use of a heavy galvanized steel wire armour. The GSWA makes them suitable for use inside and outside buildings or for direct burial in the ground. For installation where fire, smoke emission and toxic fumes create a potential threat to life and equipment.

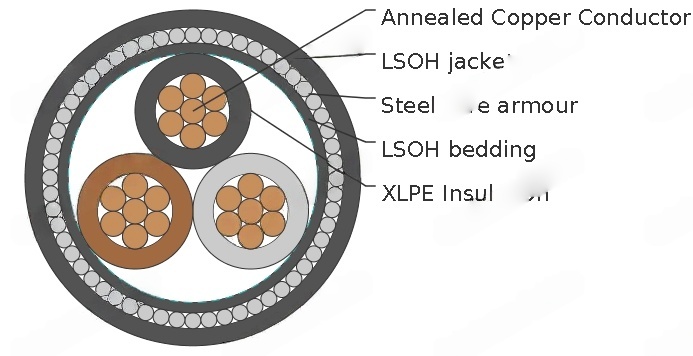

CONSTRUCTION

Conductor | Solid Aluminum or Annealed Copper conductor, circular or shaped, Class 2 to BS EN60228. |

Insulation | XLPE (Cross-Linked Polyethylene) Type GP 8 conforming to BS 7655-1.3 or type GP 6 conforming to BS 7655-1.2. |

Colour Code | 1 Core : Brown or Blue |

2 Cores : Brown, Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green/Yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Bedding | The bedding shall consist of an extruded layer of polymeric material consistent with the operating temperature of the cable. |

Armour | Single Core : AWA (Aluminum Wire Armour) |

Multi Core : GSWA (Galvanized Steel Wire Armour) | |

Outer Sheath | LSOH (Low Smoke Zero Halogen),conforming to BS 7655-6.1. |

TECHNICAL INFORMATION

Voltage rating | 1900/3300V |

Temperature rating | 0°C to +90°C |

Min. Bending radius | 8 x overall diameter |

Flame retardant | BS EN 60332-1-2 ; BS EN 60332-3-24:2009 |

Halogen free | BS EN 60754-1 |

Smoke density | BS EN 61034-2 |

CABLE PARAMETER

Nominal Cross-sectional Area | Strand Type | Nominal Insulation Thickness | Nominal Bedding Thickness | Nominal Steel Wire Armor dia. | Nominal Sheath Thickness | Approx. Overall Diameter | Aprrox. Weight |

|---|---|---|---|---|---|---|---|

mm² | No./mm | mm | mm | mm | mm | mm | kg/km |

7/1.70 | 2 | 1 | 1.6 | 1.8 | 29.3 | 1600 | |

7/2.14 | 2 | 1 | 1.6 | 1.8 | 32.2 | 2060 | |

7/2.52 | 2 | 1 | 1.6 | 1.9 | 34.8 | 2400 | |

7/2.52 | 2 | 1 | 1.6 | 1.9 | 31.1 | 2400 | |

19/1.78 | 2 | 1.2 | 2 | 2 | 34.7 | 3200 | |

19/2.14 | 2 | 1.2 | 2 | 2.1 | 38 | 3800 | |

19/2.52 | 2 | 1.2 | 2 | 2.2 | 41.4 | 4730 | |

37/2.03 | 2 | 1.4 | 2.5 | 2.3 | 45.7 | 6070 | |

37/2.25 | 2 | 1.4 | 2.5 | 2.4 | 48.5 | 7010 | |

37/2.52 | 2 | 1.4 | 2.5 | 2.5 | 51.9 | 8270 | |

61/2.25 | 2 | 1.6 | 2.5 | 2.6 | 56.9 | 10310 | |

61/2.52 | 2 | 1.6 | 2.5 | 2.7 | 61.2 | 12300 | |

61/2.85 | 2 | 1.6 | 2.5 | 2.9 | 66.6 | 14500 |

* Shaped stranded conductor (class 2)

Applications: Powering South Africa's Infrastructure

These cables excel in power and control circuits, where reliability is paramount. Their 1900/3300V rating suits medium-voltage distribution, common in South African industries like mining, where they connect transformers to equipment in underground shafts. The GSWA armour makes them suitable for direct burial, resisting soil corrosion and mechanical stress from heavy machinery.

In buildings, they're used for internal wiring, offering protection against fire hazards. The LSOH sheath aligns with South African regulations under the Occupational Health and Safety Act, reducing risks in high-occupancy structures like hospitals or schools. For outdoor applications, such as renewable energy farms in the Northern Cape, these cables link solar panels or wind turbines to substations, handling variable loads efficiently.

From an engineering viewpoint, their use in control circuits involves transmitting signals alongside power, minimising interference due to the balanced three-core design. In petrochemical plants along the Durban coast, the armour guards against chemical exposure, while the XLPE insulation maintains performance in humid, salty air.

Economically, opting for stranded copper variants justifies the higher initial cost through lower maintenance. In South Africa's push towards electrification in rural areas, these cables support grid expansion, ensuring stable supply to underserved communities. Environmentally, the halogen-free design reduces pollution, aligning with global sustainability goals like the Paris Agreement, which South Africa endorses.

Multi-Perspective Analysis

Electrical Perspective

Stranded copper conductors excel in current distribution, with skin effect minimised at 50Hz frequencies common in South Africa. The three-core balanced setup reduces electromagnetic interference, ideal for sensitive control systems.

Mechanical and Installation Perspective

The flexibility of stranded wires simplifies routing, with a bending radius of 8x diameter allowing curves without kinking. Armour protects during trenching, common in South African construction. However, installers must avoid over-bending to prevent insulation cracks.

Safety and Regulatory Perspective

LSOH and flame-retardant properties comply with SANS 10142-1 wiring codes. In fire-prone areas like informal settlements, these cables mitigate risks. The armour also deters theft, a prevalent issue in South Africa.

Environmental and Economic Perspective

Halogen-free materials lessen ecological footprints, supporting South Africa's carbon neutrality targets by 2050. Economically, while copper is pricier than aluminium, lower losses yield long-term savings—crucial for Eskom's grid upgrades.

Frequently Asked Questions (FAQs)

What are three-core 1900/3300V cables used for? Primarily for power and control in buildings, industrial sites, and direct burial. Their armour suits harsh environments, like South African mines.

Why choose stranded copper over solid? Stranded offers better flexibility and vibration resistance, reducing installation damage. Copper provides superior conductivity for efficient transmission.

How do these cables perform in fires? LSOH sheaths emit minimal smoke and no halogens, meeting BS EN standards for safety in enclosed spaces.

What is the minimum bending radius? 8 times the overall diameter—e.g., 234 mm for a 29.3 mm cable—to prevent stress on insulation.

Are they suitable for outdoor use in South Africa? Yes, with UV-resistant sheaths and armour handling soil and weather extremes from 0°C to +90°C.

How do I select the right size? Based on load current, voltage drop, and installation. For example, 3x50 mm² suits medium loads; consult SANS standards.

What's the difference between shaped and circular stranded conductors? Shaped (for larger sizes) are compacted for smaller diameters, improving space efficiency without affecting performance.

Can these cables be recycled? Yes, copper and steel are highly recyclable, aligning with sustainable practices.

What maintenance do they require? Minimal; periodic visual checks for damage, especially in buried installations.

How do they compare to aluminium conductors? Copper has lower resistance but higher cost; aluminium is lighter but needs larger sections for equivalent performance.

Three-core 1900/3300V XLPE cables with stranded copper conductors embody engineering ingenuity, blending conductivity, protection, and safety. From powering South Africa's industries to safeguarding lives in emergencies, they underscore the importance of quality materials in electrical systems. As the nation advances towards greener energy, these cables will remain indispensable. Understanding their multifaceted design empowers better choices, ensuring reliable, efficient infrastructure for generations.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430