Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Three-core 600/1000V cables with stranded copper conductors

APPLICATION

These power and control cables are used for electricity supply in low voltage installation system. They are well adapted to underground use in industrial applications where chemical and mechanical protections are needed (refinery areas, chemical plant...).

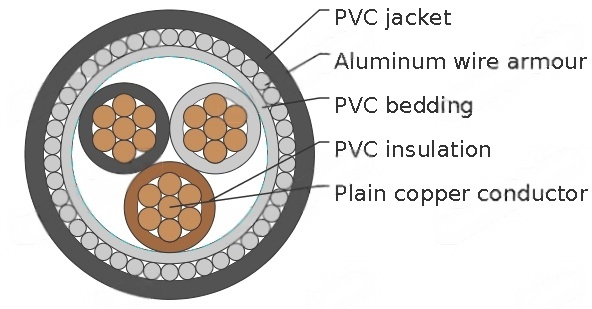

CONSTRUCTION

Conductor | Solid Aluminum or Copper conductor, round stranded or shaped, Class 2 to BS 6460, IEC 60228. |

Insulation | PVC(Polyvinyl Chloride) type TI1 |

Colour Code | 1 Core : Brown |

2 Cores : Brown or Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green-yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Filler(optional) | PVC or Polypropylene yarn |

Binder Tape(optional) | Polyester (Mylar) tape |

Inner Sheath/Bedding | PVC (Polyvinyl Chloride) |

Armour | Single Core : AWA (Aluminum Wire Armour) |

Multi Core : SWA (Steel Wire or Tape Armour) | |

Outer Sheath | PVC(Polyvinyl Chloride), type TM1 |

TECHNICAL INFORMATION

Voltage rating | 600/1000V |

Temperature rating | -20°C to +60°C |

Bending radius | Single core : 10 x overall diameter |

Multicores : 8 x overall diameter | |

Flame retardant | IEC60332 part 1, BS4066 part 1 |

CABLE PARAMETER

Nominal cross-sectional area | Number/wire | Nominal insulation thickness | Nominal bedding thickness | Nominal wire armor dia. | Nominal sheath thickness | Approx. overall diameter | Approx.cable weight | |

|---|---|---|---|---|---|---|---|---|

extruded bedding | taped bedding | |||||||

mm² | No./mm | mm | mm | mm | mm | mm | mm | kg/km |

7/0.53 | 0.6 | 0.8 | 0.9 | 1.4 | 12.8 | - | 307 | |

7/0.67 | 0.7 | 0.8 | 0.9 | 1.4 | 14.1 | - | 387 | |

7/0.85 | 0.8 | 0.8 | 0.9 | 1.4 | 15.8 | - | 493 | |

7/1.04 | 0.8 | 0.8 | 1.25 | 1.5 | 18.0 | - | 701 | |

7/1.35 | 1.0 | 0.8 | 1.25 | 1.6 | 21.2 | - | 967 | |

7/1.70 | 1.0 | 0.8 | 1.25 | 1.6 | 23.1 | 23.1 | 1219 | |

7/2.14 | 1.2 | 1.0 | 1.6 | 1.7 | 28.2 | 27.8 | 1612 | |

7/2.14 | 1.2 | 1.0 | 1.6 | 1.7 | 25.0 | 24.6 | 1612 | |

19/1.53 | 1.2 | 1.0 | 1.6 | 1.8 | 30.8 | 30.4 | 1992 | |

19/1.53 | 1.2 | 1.0 | 1.6 | 1.8 | 27.1 | 26.7 | 1992 | |

19/1.78 | 1.4 | 1.0 | 1.6 | 1.9 | 30.5 | 30.1 | 2534 | |

19/2.14 | 1.4 | 1.2 | 2.0 | 2.0 | 35.0 | 34.2 | 3518 | |

19/2.52 | 1.6 | 1.2 | 2.0 | 2.1 | 39.3 | 38.5 | 4510 | |

37/2.03 | 1.6 | 1.2 | 2.0 | 2.2 | 42.2 | 41.4 | 5375 | |

37/2.25 | 1.8 | 1.4 | 2.5 | 2.4 | 47.5 | 46.3 | 6810 | |

37/2.52 | 2.0 | 1.4 | 2.5 | 2.5 | 51.9 | 50.7 | 8190 | |

61/2.25 | 2.2 | 1.6 | 2.5 | 2.6 | 57.8 | 56.2 | 10280 | |

61/2.52 | 2.4 | 1.6 | 2.5 | 2.8 | 63.2 | 61.6 | 12430 | |

61/2.85 | 2.6 | 1.6 | 2.5 | 3.0 | 69.6 | 68.0 | 15400 | |

*Shaped stranded conductor (class 2)

Understanding Three-Core Cables in Low-Voltage Systems

To grasp the significance of three-core 600/1000V cables, let's start with the fundamentals. These are power and control cables primarily used for electricity supply in low-voltage setups, typically rated at 600 volts for phase-to-earth and 1000 volts for phase-to-phase connections. This rating makes them ideal for industrial applications where consistent power delivery is critical, but high-voltage transmission isn't required.

What sets three-core cables apart? As the name suggests, they contain three insulated conductors within a single sheath, colour-coded for easy identification: brown, black, and grey. This configuration is perfect for three-phase systems, which are common in industrial machinery, allowing for balanced power distribution and efficient operation of motors, pumps, and other equipment. Unlike single-core or two-core variants, three-core cables provide a compact solution for transmitting alternating current (AC) in a way that minimises electromagnetic interference and heat buildup.

In South Africa, where industries like mining and manufacturing face harsh conditions—think corrosive chemicals in refineries or mechanical stresses in underground tunnels—these cables shine. They're engineered to withstand temperatures from -20°C to +60°C, ensuring reliability in everything from the chilly winters of the Highveld to the humid heat of coastal plants. Their flame-retardant properties, compliant with international standards like IEC 60332 Part 1 and BS 4066 Part 1, add another layer of safety, preventing fire propagation in confined spaces.

But why focus on stranded copper conductors? Copper has long been prized for its excellent conductivity—about 1.7 times better than aluminium—meaning less energy loss during transmission. Stranded versions, made by twisting multiple thin wires (typically seven or more per conductor), offer superior flexibility compared to solid conductors. This is crucial in installations involving bends or vibrations, common in industrial settings. According to Class 2 standards from BS 6460 and IEC 60228, these strands can be round or shaped, enhancing durability without sacrificing performance.

Performance Parameters and Advantages of Stranded Copper in Three-Core Cables

Now, for the nitty-gritty: let's analyse the cable parameters, drawing from standard specifications. These cables come in nominal cross-sectional areas from 1.5 mm² to 400 mm², each with tailored dimensions.

Consider a mid-range 3x50 mm² cable with shaped stranded copper conductors (19 strands of 1.78 mm each). Insulation is 1.4 mm thick, bedding 1.0 mm, armour 1.6 mm wires, and sheath 1.9 mm, yielding an overall diameter of about 30.5 mm and weight of 2534 kg/km. Why shaped strands? They pack more densely, reducing the cable's footprint while maintaining conductivity—ideal for space-constrained installations.

Electrically, copper's low resistivity (1.68 × 10^-8 Ω·m) means these cables handle higher currents with less heating. For instance, a 3x150 mm² cable can carry substantial loads in industrial motors, with its 2.5 mm armour providing electromagnetic shielding to boot.

Mechanically, the stranding enhances fatigue resistance. In vibrating environments like pumps in chemical processing, solid conductors might crack over time, but stranded ones flex and endure. This is quantified by the bending radius: for a 3x70 mm² cable (35 mm diameter), it's 280 mm, allowing tight turns without kinking.

Chemically, PVC's resistance to hydrocarbons and acids is key in refineries. Tests show it withstands immersion in oils at 60°C without significant swelling, preserving insulation integrity.

Compared to aluminium alternatives, copper versions offer better conductivity per volume, though they're heavier and costlier. In South Africa, where copper theft is a concern, armoured designs deter pilfering. For underground use, the armour protects against soil compression and moisture ingress, with the flame-retardant sheath ensuring compliance with SANS (South African National Standards) equivalents to IEC norms.

Sustainability-wise, copper is recyclable, aligning with South Africa's green initiatives in industry. However, larger cables like 3x300 mm² (63.2 mm diameter, 12430 kg/km) demand careful handling to avoid installation strain.

In essence, these cables balance conductivity, protection, and flexibility, making them a cornerstone for reliable power in demanding settings.

Frequently Asked Questions: Demystifying Three-Core 600/1000V Cables

To wrap up our exploration, here are answers to some common queries, based on standard technical data.

What is the voltage rating, and why 600/1000V? These cables are rated for 600V phase-to-earth and 1000V phase-to-phase, suitable for low-voltage distribution. This dual rating ensures safety margins in fluctuating industrial supplies, preventing breakdowns under minor surges.

How does the temperature rating affect usage in South Africa? Rated from -20°C to +60°C, they're versatile for our diverse climates—from frosty Free State mines to hot KwaZulu-Natal factories. Beyond +60°C, derating factors apply to avoid insulation softening.

What's the difference between round and shaped stranded conductors? Round strands (e.g., in 3x10 mm² with 7/1.35 mm) are more flexible for dynamic installations. Shaped ones (marked with * in specs, like 3x50 mm²) are compacted for smaller diameters, saving space in conduits but slightly less bendable.

Why choose steel wire armour over other protections? SWA provides superior mechanical strength against crushing or cuts, essential underground. For three-cores, it's standard, with diameters like 1.25 mm for smaller sizes scaling to 2.5 mm for larger, balancing weight and toughness.

Are these cables flame retardant, and how is it tested? Yes, compliant with IEC 60332 Part 1, where a flame is applied for 60 seconds without spreading. This is vital in chemical plants to contain fires.

How do I select the right cross-sectional area? It depends on current load and distance. For example, 3x6 mm² (18 mm diameter) suits lighter duties, while 3x240 mm² (57.8 mm) handles heavy machinery. Consult ampacity tables for precise sizing.

Can these be used outdoors or only underground? While optimised for buried installations, their PVC sheath allows above-ground use if protected from UV. In refineries, underground routing minimises exposure.

What's the approximate weight and diameter for a typical installation? For 3x35 mm² (round strands), it's 30.8 mm diameter and 1992 kg/km. Shaped versions are slimmer (27.1 mm), easing handling.

How does PVC insulation compare to other materials? PVC is cost-effective and durable but less heat-resistant than XLPE. For 600/1000V, it's sufficient, with thicknesses ensuring dielectric strength.

Are there options for more than three cores? The specs mention up to five cores with green-yellow earth, and above that, numbered whites. But three-cores are standard for balanced three-phase power.

Three-core 600/1000V cables with stranded copper conductors aren't just wires—they're engineered lifelines for industrial resilience. From their flexible strands to robust armour, they embody innovation tailored for harsh realities. As South Africa pushes towards sustainable industrial growth, understanding these cables empowers better decisions in energy infrastructure. Next time you flick a switch in a factory, remember the underground guardians making it possible.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430