Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Three-core 600/1000V cables with stranded copper conductors

APPLICATION

These cables are used for power and control circuits, they can offer excellent protection through the use of a heavy galvanized steel wire armour. The GSWA makes them suitable for use inside and outside buildings or for direct burial in the ground. For installation where fire, smoke emission and toxic fumes create a potential threat to life and equipment.

CONSTRUCTION

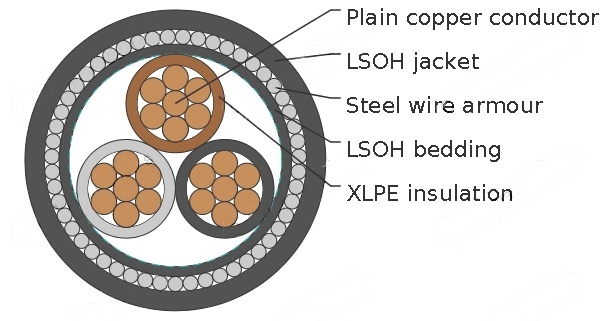

Conductor | Solid Aluminum or Annealed Copper conductor, circular or shaped, Class 2 to BS EN60228. |

Insulation | XLPE (Cross-Linked Polyethylene) Type GP 8 conforming to BS 7655-1.3 or type GP 6 conforming to BS 7655-1.2. |

Colour Code | 1 Core : Brown or Blue |

2 Cores : Brown, Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green/Yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Bedding | The bedding shall consist of an extruded layer of polymeric material consistent with the operating temperature of the cable. |

Armour | Single Core : AWA (Aluminum Wire Armour) |

Multi Core : GSWA (Galvanized Steel Wire Armour) | |

Outer Sheath | LSOH (Low Smoke Zero Halogen),conforming to BS 7655-6.1. |

TECHNICAL INFORMATION

Voltage rating | 600/1000V |

Temperature rating | 0°C to +90°C |

Min. Bending radius | 8 x overall diameter |

Flame retardant | BS EN 60332-1-2 ; BS EN 60332-3-24:2009 |

Halogen free | BS EN 60754-1 |

Smoke density | BS EN 61034-2 |

CABLE PARAMETER

Nominal Cross-sectional Area | Strand Type | Nominal Insulation Thickness | Nominal BeddingThickness | Nominal Steel Wire Armor dia. | Nominal Sheath Thickness | Approx. Overall Diameter | Aprrox. Weight |

|---|---|---|---|---|---|---|---|

mm² | No./mm | mm | mm | mm | mm | mm | kg/km |

7/0.53 | 0.6 | 0.8 | 0.9 | 1.3 | 12.6 | 340 | |

7/0.67 | 0.7 | 0.8 | 0.9 | 1.4 | 14.1 | 408 | |

7/0.85 | 0.7 | 0.8 | 0.9 | 1.4 | 15.3 | 498 | |

7/1.04 | 0.7 | 0.8 | 0.9 | 1.4 | 16.6 | 600 | |

7/1.35 | 0.7 | 0.8 | 1.25 | 1.5 | 19.5 | 915 | |

7/1.70 | 0.7 | 0.8 | 1.25 | 1.6 | 21.6 | 1130 | |

7/2.14 | 0.9 | 1 | 1.6 | 1.7 | 26.7 | 1710 | |

7/2.14 | 0.9 | 1 | 1.6 | 1.7 | 23.6 | 1710 | |

7/2.52 | 0.9 | 1 | 1.6 | 1.8 | 29.4 | 2100 | |

7/2.52 | 0.9 | 1 | 1.6 | 1.8 | 25.7 | 2100 | |

19/1.78 | 1.0 | 1 | 1.6 | 1.8 | 28.5 | 2450 | |

19/2.14 | 1.1 | 1 | 1.6 | 1.9 | 32.2 | 3120 | |

19/2.52 | 1.1 | 1.2 | 2.0 | 2.1 | 37.0 | 4310 | |

37/2.03 | 1.2 | 1.2 | 2.0 | 2.2 | 40.4 | 5160 | |

37/2.25 | 1.4 | 1.4 | 2.5 | 2.3 | 45.5 | 7160 | |

37/2.52 | 1.6 | 1.4 | 2.5 | 2.4 | 49.8 | 8600 | |

61/2.25 | 1.7 | 1.4 | 2.5 | 2.6 | 55.1 | 10755 | |

61/2.52 | 1.8 | 1.6 | 2.5 | 2.7 | 60.2 | 13080 | |

61/2.85 | 2 | 1.6 | 2.5 | 2.9 | 66.6 | 15810 |

*Shaped stranded conductor (class 2)

Introduction

In the world of electrical engineering, cables are the unsung heroes that keep our homes, industries, and infrastructure powered up. But have you ever wondered what goes into making a cable tough enough to handle the demands of modern power systems? Enter the three-core 600/1000V armoured cable with stranded copper conductors – a robust solution designed for reliability and safety. These cables, often referred to as SWA (Steel Wire Armoured) cables due to their galvanized steel wire armour, are engineered to withstand harsh environments while delivering efficient power and control.

Applications

Three-core 600/1000V armoured cables are versatile workhorses in electrical installations. Their primary role is in power and control circuits, where they transmit electricity safely and efficiently. What sets them apart is their heavy galvanized steel wire armour (GSWA), which offers exceptional mechanical protection. This makes them suitable for use inside buildings, outside in exposed areas, or even directly buried in the ground.

Imagine a bustling industrial site in Johannesburg or a rural farm in the Western Cape – these cables can handle it all. The armour shields against physical damage, such as impacts from tools, rodents, or accidental digs during construction. In South Africa, where infrastructure projects often involve challenging terrains like rocky soils or flood-prone areas, this protection is invaluable.

Moreover, these cables are designed for scenarios where fire safety is paramount. The low smoke zero halogen (LSOH) outer sheath minimises smoke emission and toxic fumes in case of fire, reducing risks to life and equipment. This aligns with South African building regulations, such as those under the National Building Regulations and Building Standards Act, which emphasise fire-retardant materials in public and commercial spaces.

In essence, the application of three-core armoured cables extends beyond mere power delivery; they ensure longevity and safety in environments prone to mechanical stress or fire hazards. For instance, in mining operations – a cornerstone of South Africa's economy – these cables power machinery deep underground, where durability is non-negotiable.

Advantages of Stranded Copper in Three-Core Designs

Stranded copper conductors excel in three-core 600/1000V armoured cables for several reasons. First, stranding mitigates skin effect – where AC current flows more on the conductor's surface – by increasing surface area, improving efficiency at 50 Hz frequencies used in South Africa.

Mechanically, strands resist fatigue from vibrations, common in transport or mining applications. Copper's malleability allows tighter bends without cracking, with the 8x diameter radius ensuring safe installation.

Compared to aluminium, copper offers better conductivity (about 1.6 times higher), though heavier and costlier. In armoured setups, this weight is offset by the protection, making copper preferable for critical circuits.

The three-core configuration suits balanced three-phase systems, reducing neutral current and harmonic issues. With GSWA, electromagnetic compatibility is enhanced, as the steel provides grounding paths.

However, challenges include higher initial costs and the need for proper termination to avoid corrosion. In humid coastal areas like Durban, the galvanized armour proves its worth.

Scientifically, the cable's impedance can be modelled as Z = R + jωL, where R is resistance (lower with copper) and L inductance (influenced by armour). This ensures stable power delivery.

Frequently Asked Questions (FAQs)

What is the difference between stranded and solid conductors in these cables? Stranded conductors, like those in these three-core cables, consist of multiple wires for flexibility and durability, ideal for installations requiring bending. Solid ones are stiffer but cheaper for straight runs.

Are these cables suitable for underground installation? Yes, the GSWA protects against soil pressure and rodents, making direct burial feasible without additional conduits.

How do I select the right cross-sectional area? It depends on load current, voltage drop, and distance. For example, use 3×10 mm² for moderate loads up to 50A per phase.

What makes them fire-safe? The LSOH sheath and flame-retardant standards ensure low smoke and no halogens, complying with South African safety norms.

Can they be used outdoors in South Africa? Absolutely, with UV-resistant sheaths and corrosion-proof armour handling varied weather from Cape Town's rains to Limpopo's heat.

What's the lifespan? Typically 25-40 years, depending on installation and maintenance, thanks to XLPE's longevity.

Three-core 600/1000V armoured cables with stranded copper conductors represent a pinnacle of electrical engineering, blending science, safety, and practicality. From their flexible strands to protective armour, they ensure reliable power in diverse applications. In South Africa, where infrastructure resilience is key, these cables power progress while prioritising safety. Next time you flip a switch, remember the intricate design keeping the lights on.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430