Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

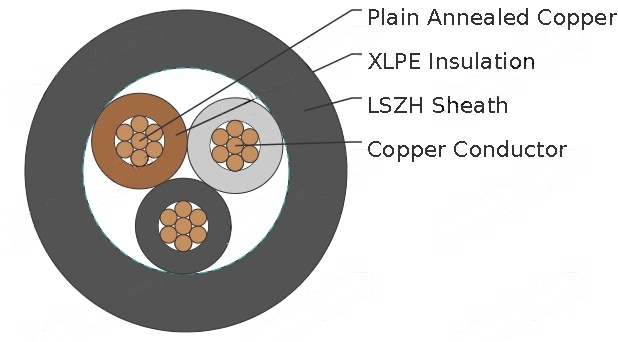

Three-core 600/1000V XLPE Insulation, LSZH Sheath Cables to BS 8573

Application

These XLPE insulated and LSZH sheathed cables are generally used for fixed installation. Suitable for building wiring, especially in areas where smoke and fume emissions may cause a potential threat to life but not for burial in the ground, either directly or in ducts.

Standard

Basic design to BS 8573:2012

Fire Performance

Flame Retardance (Single Vertical Wire Test) | BS EN 60332-1-2:2004 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) | BS EN 60332-3-24:2009 (cat. C) |

Halogen Free | BS EN 50267-2-1 |

Minimum Smoke Emission | BS EN 61034-2 |

Spark Test | BS EN 62230 |

Voltage Rating

600/1000V

Construction

Conductor : Annealed copper conductor, strand according to BS EN 60228 class 2.

Insulation : XLPE type GP8 according to BS 7655-1.3. HEPR type GP6 according to BS 7655-1.2, or crosslinked polyolefin material type EI 5 according to BS EN 50363-5 can be offered as option.

Inner Covering option : The laid up cores may be coverd by an optional extrued inner covering or separating tape. It shall be possible to separate the cores easily.

Outer Sheath : Thermoplastic LSZH type LTS 4 according to BS 7655-6.1.

Outer Sheath option : UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option.

Color Code

Insulation Colour : Brown, black and grey

Sheath Colour : Black, other colours can be offered upon request.

Physical And Thermal Properties

Maximum temperature range during operation (XLPE) : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius:

Circular copper conductors(up to 25mm²) : 4 x Overall Diameter

Circular copper conductors(above 25mm²) : 6 x Overall Diameter

Shaped copper conductors : 8 x Overall Diameter

Construction Parameters

Conductor | Nominal Insulation Thickness | Nominal Inner Covering Thickness | Nominal Sheath Thickness | |

|---|---|---|---|---|

No. of Cores x Cross Section | Class of Conductor | |||

No. x mm² |

| mm | mm | mm |

2 | 0.7 | 0.4 | 1.8 | |

2 | 0.7 | 0.4 | 1.8 | |

2 | 0.7 | 0.4 | 1.8 | |

2 | 0.7 | 0.4 | 1.8 | |

2 | 0.7 | 0.6 | 1.8 | |

2 | 0.7 | 0.6 | 1.8 | |

2 | 0.9 | 0.8 | 1.8 | |

2 | 0.9 | 0.8 | 1.8 | |

2 | 1.0 | 1.0 | 1.8 | |

2 | 1.1 | 1.2 | 1.9 | |

2 | 1.1 | 1.2 | 2.0 | |

2 | 1.2 | 1.2 | 2.1 | |

2 | 0.9 | 0.6 | 1.8 | |

2 | 0.9 | 0.8 | 1.8 | |

2 | 1.0 | 0.8 | 1.8 | |

2 | 1.1 | 1.0 | 1.9 | |

2 | 1.1 | 1.2 | 2.0 | |

2 | 1.2 | 1.2 | 2.1 | |

Introduction

In an era where electrical safety and environmental considerations are paramount, the choice of cabling in fixed installations can make the difference between a reliable system and a potential hazard. Three-core 600/1000V XLPE insulated LSZH sheathed cables, designed to BS 8573:2012 standards, represent a sophisticated solution tailored for modern building wiring. These cables, featuring cross-linked polyethylene (XLPE) insulation and low smoke zero halogen (LSZH) sheathing, are engineered to minimise risks in environments where smoke and toxic fumes could endanger lives. But what exactly makes these cables indispensable, and how do they perform under various conditions?

Applications and Suitability

Three-core XLPE insulated LSZH sheathed cables are primarily intended for fixed installations in buildings, where they serve as essential components for power distribution and wiring systems. Their design makes them particularly suitable for areas prone to high occupancy or where evacuation could be challenging, such as schools, shopping centres, and office blocks. Unlike traditional PVC cables, which can release dense smoke and harmful halogens during fires, LSZH variants ensure minimal smoke emission, preserving visibility and reducing inhalation risks.

From an application perspective, these cables are not recommended for direct burial in the ground or in ducts, as their construction prioritises indoor use. Instead, they excel in structured cabling setups, including conduits, trays, and clips within walls or ceilings. In South Africa, where building regulations increasingly demand compliance with international standards like BS 8573, these cables align with local codes under the SANS (South African National Standards) framework, which often references British standards for electrical safety.

Consider a scenario in a multi-storey hospital: reliable power supply is critical, but so is fire safety. Here, the three-core configuration—typically comprising brown, black, and grey insulated cores—facilitates balanced three-phase distribution at 600/1000V, ensuring efficient energy transfer without excessive heat buildup. The LSZH sheath further enhances suitability by resisting the spread of flames, making these cables ideal for environments where human life is at stake.

Fire Performance Analysis

One of the standout features of three-core XLPE insulated LSZH sheathed cables is their exceptional fire performance, a critical perspective in fire-prone environments. Tested to BS EN 60332-1-2:2004 for flame retardance in single vertical wire scenarios, these cables resist ignition and self-extinguish quickly, preventing fire spread along the cable length.

Further scrutiny under BS EN 60332-3-24:2009 (Category C) evaluates reduced fire propagation in bundled installations, simulating real-world cable trays in buildings. Here, the LSZH sheath plays a pivotal role by limiting flame spread and ensuring the cables do not contribute to a larger blaze. Halogen-free compliance per BS EN 50267-2-1 means no release of corrosive gases like hydrogen chloride, which can damage equipment and harm respiratory systems.

Minimum smoke emission, as per BS EN 61034-2, is another key metric: in fire tests, these cables produce translucent smoke, allowing for better visibility during evacuations. From a safety perspective, this is invaluable in densely populated areas, where panic can exacerbate casualties. In South Africa, where wildfires and urban fires are common risks, adopting LSZH cables aligns with national fire safety initiatives, such as those promoted by the Fire Protection Association of Southern Africa.

Comparatively, traditional halogenated cables might save costs initially but pose higher long-term risks. An economic analysis shows that while LSZH options may cost 10-20% more, they reduce insurance premiums and potential litigation from fire incidents, offering a favourable return on investment.

In-Depth Multi-Perspective Analysis

Analysing from a technical viewpoint, the combination of XLPE and LSZH yields superior electrical performance, with low dielectric losses and high insulation resistance. This translates to efficient power transmission, minimising energy wastage—a key concern amid South Africa's electricity challenges.

Environmentally, the halogen-free design supports eco-friendly disposal and reduces pollution during manufacturing. In a country grappling with waste management, LSZH cables align with circular economy principles, as their materials are recyclable.

Economically, while initial costs are higher, lifecycle benefits include lower maintenance and extended service life (often 30+ years). Safety-wise, they mitigate risks in high-stakes scenarios, as evidenced by case studies from European installations where LSZH cables saved lives during fires.

From an innovation perspective, ongoing advancements in cross-linking techniques could further enhance properties, potentially integrating smart sensors for real-time monitoring.

Three-core 600/1000V XLPE insulated LSZH sheathed cables to BS 8573 embody a blend of safety, efficiency, and adaptability, making them essential for contemporary electrical systems. Their multifaceted advantages—from fire retardance to thermal stability—position them as a forward-thinking choice, especially in safety-conscious regions like South Africa.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430