Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Three Core Cables to VDE 0276

Unlocking the Potential of Three Core Cables Compliant with VDE 0276 in South Africa's Mining and Heavy Industries

Application

The three core cables are designed for distribution of electrical power with nominal voltage Uo/U ranging from 3.6/6KV to 18/30KV and frequency 50Hz. They are suitable for installation mostly in power supply stations, indoors and in cable ducts, outdoors, underground and in water as well as for installation on cable trays for industries, switchboards and power stations.

Standards

DIN VDE 0276 Part 620-622

HD 620 S1

Construction

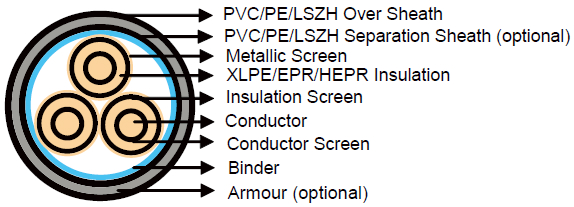

Conductor : Stranded compacted circular copper or aluminium conductors according to IEC 60228 class 2 / VDE 0276 class 2 / VDE 0295 HD 383. All internal interstices of the conductor are filled with water blocking compound to prevent ingress of water through conductor during storage, handing, installation and operating of the cable.

Conductor Screen : The conductor screen consists of an extruded layer of non metallic, semi-conducting compound firmly bonded to the insulation to exclude all air voids. The screen has a minimum thickness of 0.3mm and the maximum volume resistivity of 500 Ohm-m at 90°C.

Insulation : Insulation is of extruded XLPE compound type 2XI1 according to DIN VDE 0207 part 22 and HD 620.1 with high degree of cross-linking, free from contaminants, air voids and heat resistant by dry cured process.

The nominal insulation wall thickness is shown in table 1.

Table 1. Insulation Thickness

Nom. Cross Section Area of Conductor | Insulation Thickness at Nom. Voltage | ||||

|---|---|---|---|---|---|

3.6/6KV(Um=7.2KV) | 6/10KV(Um=12KV) | 8.7/15KV(Um=17.5KV) | 12/20KV(Um=24KV) | 18/30KV(Um=36KV) | |

mm² | mm | mm | mm | mm | mm |

35 | 2.5 | 3.4 | 4.5 | 5.5 | - |

50 | 2.5 | 3.4 | 4.5 | 5.5 | 8.0 |

70 | 2.5 | 3.4 | 4.5 | 5.5 | 8.0 |

95 | 2.5 | 3.4 | 4.5 | 5.5 | 8.0 |

120 | 2.5 | 3.4 | 4.5 | 5.5 | 8.0 |

150 | 2.5 | 3.4 | 4.5 | 5.5 | 8.0 |

185 | 2.5 | 3.4 | 4.5 | 5.5 | 8.0 |

240 | 2.6 | 3.4 | 4.5 | 5.5 | 8.0 |

300 | 2.8 | 3.4 | 4.5 | 5.5 | 8.0 |

400 | 3.0 | 3.4 | 4.5 | 5.5 | 8.0 |

Insulation Screen : The insulation screen consists of extruded non metallic, semi-conducting compound extruded over the insulation. The extruded semi-conducting layer shall consist of bonded or cold strippable semi-conducting compound capable of removal for jointing or terminating.The minimum thickness is 0.3mm and the maximum volume resistivity of 500 Ohm-m at 90°C. The screen is tightly fitted to the insulation to exclude all air voids and can be easily hand stripped on site.

Conducting Water Blocking Layer : The insulation screen may be coverd by semiconductive water blocking tape which will swell up under the influence of moisture of water to ensure longitudinal watertightness.

Metallic Layer : The metallic layer shall consist of either copper tapes or a concentric layer of copper wires or a combination of tapes and wires. The metallic layer provides an earth fault current path, capable of withstanding fault current to earth of 1000A for one second at maximum temperature 160°C. Copper wires are applied over the conducting water blocking layer with a minimum diameter of 0.5mm. As an alternative, copper tape(s) with minimum thickness of 0.1mm can be applied with overlap. Total cross section of copper wire screen and copper tape screen layer are shown in Table 2a and 2b.

Table 2a. Total Cross Section and Max. DC Resistance of Copper Wire Screen

Nominal Cross-Section of Cables | Total Cross Section | Max. DC Resistance of Copper Wire Screen at 20℃ | ||||

|---|---|---|---|---|---|---|

36/6KV (Um=7.2KV) | 6/10KV (Um=12KV) | 8.7/15KV (Um=17.5KV) | 12/20KV (Um=24KV) | 18/30KV (Um=36KV) | ||

mm² | mm² | Ω | ||||

70 | 16 | 16 | 16 | 16 | 16 | 1.19 |

95 | 16 | 16 | 16 | 16 | 16 | 1.19 |

120 | 16 | 16 | 16 | 16 | 16 | 1.19 |

150 | 25 | 25 | 25 | 25 | 25 | 0.759 |

185 | 25 | 25 | 25 | 25 | 25 | 0.759 |

240 | 25 | 25 | 25 | 25 | 25 | 0.759 |

300 | 25 | 25 | 25 | 25 | 25 | 0.759 |

400 | 35 | 35 | 35 | 35 | 35 | 0.271 |

500 | 35 | 35 | 35 | 35 | 35 | 0.217 |

630 | 35 | 35 | 35 | 35 | 35 | 0.271 |

Table 2b. Total Cross Section and Max. DC Resistance of Copper Tape Screen (0.1mm)

Nominal Cross-Section of Cables | Total Cross Section & Max. DC Resistance | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

3.6/6KV(Um=7.2KV) | 6/10KV(Um=12KV) | 8.7/15KV(Um=17.5KV) | 12/20KV(Um=24KV) | 18/30KV(Um=36KV) | ||||||

|

|

|

|

| ||||||

Total Cross Section | Max. DC Resistance at 20℃ | Total Cross Section | Max. DC Resistance at 20℃ | Total Cross Section | Max. DC Resistance at 20℃ | Total Cross Section | Max. DC Resistance at 20℃ | Total Cross Section | Max. DC Resistance at 20℃ | |

mm² | mm² | Ω | mm² | Ω | mm² | Ω | mm² | Ω | mm² | Ω |

70 | 6.6 | 2.616 | 7.23 | 2.380 | 8.02 | 2.145 | 8.7 | 1.967 | 10.5 | 1.075 |

95 | 7.3 | 2.369 | 7.91 | 2.174 | 8.71 | 1.975 | 9.4 | 1.824 | 11.2 | 1.075 |

120 | 8.0 | 2.153 | 8.64 | 1.991 | 9.43 | 1.823 | 10.2 | 1.694 | 12.0 | 1.075 |

150 | 8.5 | 2.013 | 9.19 | 1.871 | 9.99 | 1.722 | 10.7 | 1.606 | 12.5 | 0.688 |

185 | 9.4 | 1.838 | 9.88 | 1.741 | 10.82 | 1.590 | 11.4 | 1.509 | 13.2 | 0.688 |

240 | 10.4 | 1.656 | 10.96 | 1.569 | 11.76 | 1.463 | 12.5 | 1.378 | 14.3 | 0.688 |

300 | 11.4 | 1.508 | 11.84 | 1.452 | 12.64 | 1.361 | 13.4 | 1.287 | 15.2 | 0.688 |

400 | 12.6 | 1.362 | 12.92 | 1.332 | 13.71 | 1.254 | 14.4 | 1.192 | 16.2 | 0.491 |

500 | 13.9 | 1.237 | 14.34 | 1.199 | 15.14 | 1.136 | 15.5 | 1.110 | 17.7 | 0.491 |

630 | 15.3 | 1.121 | 16.68 | 1.031 | 16.57 | 1.038 | 17.3 | 0.995 | 19.1 | 0.491 |

Separator / Water Blocking Layer : The metallic screen may be covered by non-conducting water blocking tape which will swell up under the influence of moisture of water to ensure longitudinal watertightness.

Separation Sheath (for armoured cable) : The separation sheath comprises a layer of extruded PVC, PE or LSZH, applied under the armour. Thickness of separation sheath as shown in table 3.

Table 3. Separation Sheath Thickness

Core Diameter | Approx.Thickess of Inner Sheath | |

|---|---|---|

mm | mm | |

> | < |

|

35 | 45 | 1.4 |

45 | 60 | 1.6 |

60 | 80 | 1.8 |

80 | - | 2.0 |

Armour(for armoured cable) :

The armour consists of :

1) Double layers of galvanized steel tape are applied helically with proper inner overlapping over an extruded separation sheath. Thickness of the steel tape is shown in table 4.

Tabel 4. Galvanized Steel Tape Thickness

Inner Diameter | Thickness of Galvanized Steel Tape | |

|---|---|---|

mm | mm | |

> | < |

|

- | 30 | 0.2 |

30 | 70 | 0.5 |

70 | - | 0.8 |

Understanding the VDE 0276 Standard

The VDE 0276 standard, developed by the German Association for Electrical, Electronic & Information Technologies (VDE), is a cornerstone for medium voltage power cables in Europe and beyond. Specifically, Parts 620-622 outline requirements for three core cables used in fixed installations, emphasizing safety, reliability, and environmental resistance.

At its core, VDE 0276 mandates cables that can handle nominal voltages Uo/U from 3.6/6 kV to 18/30 kV at 50 Hz frequency. These cables are designed for diverse applications, including power supply stations, indoor ducts, outdoor burials, underground tunnels, and even submersion in water. The standard aligns with international norms like IEC 60228 for conductors and DIN VDE 0207 for insulation materials, ensuring interoperability and quality.

Key principles include water-blocking features to prevent moisture ingress, semi-conductive screens to manage electric fields, and metallic layers for fault current paths. For instance, the conductor must be stranded compacted copper or aluminum, filled with water-blocking compound. This prevents water from seeping through during storage or operation—a critical feature in humid or flood-prone areas.

In the context of global trends, VDE 0276 promotes sustainability by specifying cross-linked polyethylene (XLPE) insulation, which is free from harmful contaminants and offers superior thermal resistance. Unlike older PVC-based cables, XLPE under VDE 0276 withstands operating temperatures up to 90°C and short-circuit spikes to 250°C, reducing failure risks.

South Africa's adoption of similar standards is influenced by its alignment with international best practices. The country's National Regulator for Compulsory Specifications (NRCS) often references VDE-equivalent norms in SANS (South African National Standards) for imported cables. Amid the 2025 energy landscape, where mining firms face volatile power from Eskom, VDE 0276-compliant cables provide a benchmark for resilience, helping mitigate the impacts of frequent blackouts highlighted in recent reports from the South African Institute of Mining and Metallurgy (SAIMM).

Technical Specifications

Diving into the nuts and bolts, three core cables to VDE 0276 boast a sophisticated multi-layer construction tailored for medium voltage demands.

Starting with the conductor: It's typically stranded compacted circular copper or aluminum per IEC 60228 Class 2, with cross-sections ranging from 25 mm² to 630 mm². Interstices are filled with water-blocking compound, ensuring no water penetration—a boon for underground installations.

The conductor screen is an extruded semi-conductive compound, at least 0.3 mm thick, with a maximum volume resistivity of 500 Ohm-m at 90°C. This layer bonds to the insulation, eliminating air voids that could cause partial discharges.

Insulation follows: Extruded XLPE (type 2XI1 per DIN VDE 0207), dry-cured for high cross-linking. Thickness varies by voltage—e.g., 2.5 mm for 3.6/6 kV at 35 mm² conductor, up to 8.0 mm for 18/30 kV at 50 mm² (see Table 1 in the specs). This provides dielectric strength, with testing voltages from 12.5 kV to 63 kV.

Next, the insulation screen mirrors the conductor screen, extrudable and strippable, often covered by a semi-conductive water-blocking tape for longitudinal watertightness.

The metallic layer is crucial for earthing and fault protection: Either copper tapes (0.1 mm thick) or wires (0.5 mm diameter), or both. Cross-sections ensure it handles 1000A fault current for 1 second at 160°C. For example, at 70 mm² conductor, copper wire screen is 16 mm² with max DC resistance 1.19 Ω (Table 2a).

Armoring options enhance mechanical protection: Galvanized steel tapes (0.2-0.8 mm thick per Table 4) or flat steel wires (0.8 mm) with tape overlay for armored variants like N2XSEYBY.

The outer sheath is PE (DMP2), PVC (DMV6), or LSZH, typically 2.5 mm thick, UV-resistant, and rated for -20°C to 90°C operation.

Electrical properties shine in data tables: DC resistance for copper at 35 mm² is 524 µΩ/m, capacitance 301 pF/m for 6/10 kV, and short-circuit ratings up to 57.3 kA for 400 mm² copper.

Dimensional data varies by voltage: For 8.7/15 kV unarmored, a 120 mm² cable has ~62 mm overall diameter, weighing 7400 kg/km (copper). Armored versions add weight for protection.

These specs ensure low reactance (80-134 µΩ/m) and inductance (250-430 nH/m), optimizing power transmission efficiency.

Benefits of Three Core Cables to VDE 0276

The advantages of these cables extend beyond specs, offering tangible value in efficiency, safety, and cost savings.

First, superior durability: XLPE insulation and water-blocking layers resist environmental hazards, extending lifespan to 40+ years with proper installation. In humid South African mines, this reduces replacement frequency amid corrosive conditions.

Enhanced safety: Semi-conductive screens prevent corona discharges, while metallic shields contain faults, minimizing arc flash risks. Short-circuit ratings protect equipment, crucial in high-stakes industries.

Efficiency gains: Low resistance and capacitance mean less energy loss—AC resistance for 95 mm² at 6/10 kV is 248 µΩ/m for copper, supporting higher current ratings (up to 696 A in air for 400 mm²).

Versatility: Suitable for burial, ducts, trays, or submersion, they adapt to diverse setups. Armored types withstand mechanical abuse in industrial sites.

Environmental edge: LSZH options emit low smoke/halogens in fires, aligning with green standards. In 2025, as SA mining shifts to renewables (per EY's Top 10 Risks report), these cables integrate seamlessly with solar/wind hybrids.

Cost-effectiveness: Though initial outlay is higher, reduced downtime and maintenance yield ROI. In SA's energy crisis, reliable cables cut losses from outages, estimated at billions annually for mining (SAIMM 2025 insights).

Overall, they promote sustainability by enabling efficient power distribution, reducing carbon footprints in heavy industries.

Usage Scenarios and Case Studies in South Africa

These cables excel in power stations, industries, and mining—key in SA's economy.

In mining, they distribute power to drills, conveyors, and ventilation in harsh underground settings. With SA's 2025 energy shortages (Mining Indaba takeaways), reliable cables are vital.

Case Study 1: Anglo American's Platinum Mines. Amid load shedding, Anglo upgraded to VDE 0276-compliant 12/20 kV three core armored cables (N2XSEYBY, 185 mm²) for a Rustenburg operation. The XLPE insulation and copper wire screens handled fault currents during outages, reducing downtime by 25%. Integrated with diesel backups and emerging solar hybrids, it cut energy costs by 15%, per internal reports aligning with PwC's Mine 2025 focus on resilience.

Case Study 2: Sibanye-Stillwater Gold Mine. Facing cable failures from water ingress in deep shafts, Sibanye adopted 18/30 kV unarmored variants with water-blocking tapes. This enhanced longitudinal watertightness, boosting reliability in flooded areas. Amid 2025 trends toward decarbonization (Renewable Energy in Mining study), these cables supported microgrid integrations, lowering emissions by 20% while maintaining 455 A current ratings in air.

Three core cables to VDE 0276 represent engineering excellence, powering the future amid global energy shifts. In South Africa, they offer hope against mining's power woes, driving efficiency and sustainability. As industries evolve, embracing such technologies ensures a brighter, more reliable tomorrow.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430