Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

TROMMELFLEX (KSM-S) (N)SHTOEU: Low Voltage Reeling Cable for E-RTG‘s

eichun TROMMELFLEX (KSM-S) (N)SHTOEU: The Ultimate Low Voltage Reeling Cable for E-RTG Cranes in Heavy Industry

TROMMELFLEX (KSM-S) (N)SHTOEU: Low Voltage Reeling Cable for E-RTG‘s

In the fast-evolving world of heavy industry, particularly in South Africa’s mining and port sectors, the demand for reliable, durable, and high-performance cabling solutions is paramount. The Feichun TROMMELFLEX (KSM-S) (N)SHTOEU low voltage reeling cable stands out as a cutting-edge solution designed specifically for Electrified Rubber Tyred Gantry (E-RTG) cranes. These cranes, critical to material handling in ports, mining, and logistics, require cables that can withstand constant movement, harsh environmental conditions, and heavy mechanical stresses while ensuring seamless power and data transmission. This article explores the TROMMELFLEX cable’s technical specifications, benefits, applications, and its relevance to South Africa’s industrial landscape, with a focus on its role in enhancing operational efficiency and safety.

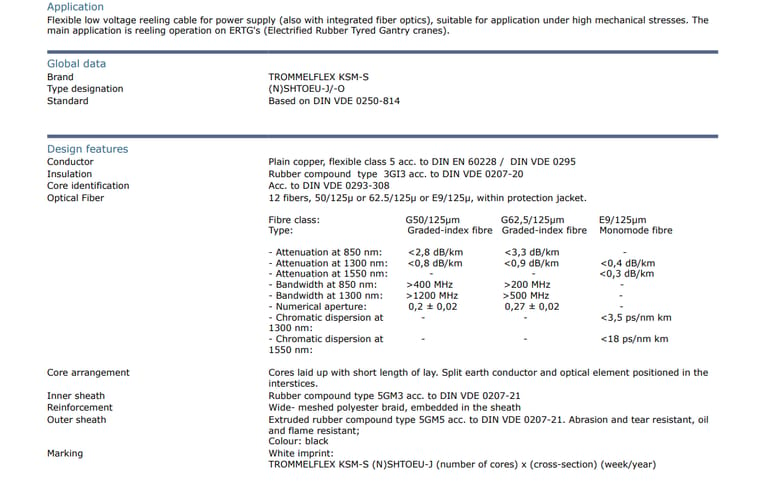

What is the TROMMELFLEX (KSM-S) Cable?

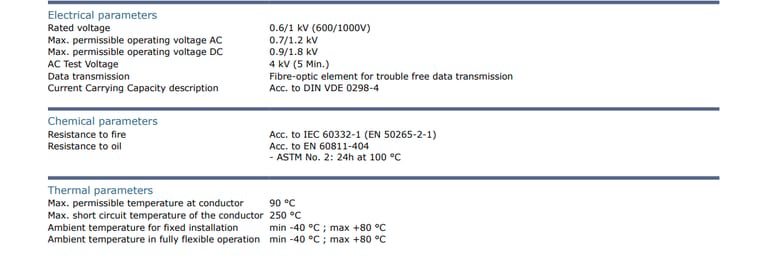

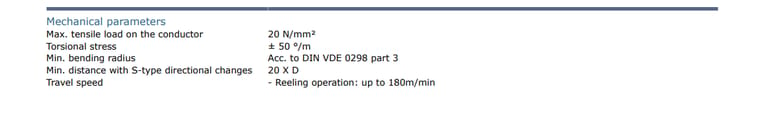

The TROMMELFLEX (KSM-S) (N)SHTOEU is a low voltage reeling cable engineered for applications under high mechanical stress, such as E-RTG cranes. Unlike standard cables, it combines robust power transmission with integrated fiber optic capabilities, enabling simultaneous energy delivery and high-speed data communication. This dual functionality makes it ideal for modern industrial systems where efficiency and connectivity are critical. Based on the DIN VDE 0250-814 standard, the cable is designed to meet the rigorous demands of continuous reeling operations, offering unmatched durability, flexibility, and resistance to environmental challenges.

Cable Types and Configurations

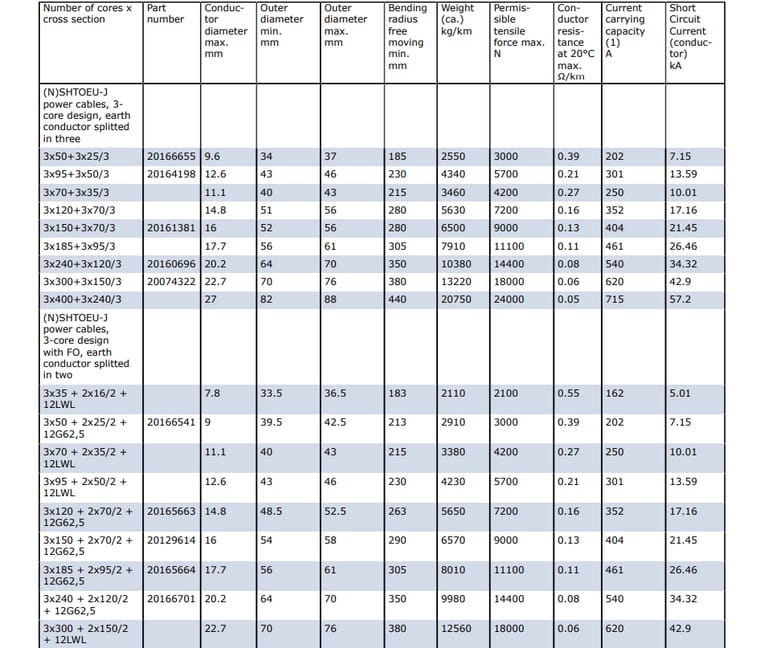

The TROMMELFLEX KSM-S is available in multiple configurations to suit various operational needs:

3-Core Design with Split Earth Conductor: Options like 3x50+3x25/3 or 3x185+3x95/3, tailored for high-power applications.

3-Core Design with Fiber Optics: Configurations such as 3x50+2x25/2+12G62,5, integrating 12 fiber optic elements for data transmission.

Cross-Section Variability: Ranging from 35 mm² to 400 mm², supporting diverse current-carrying capacities (162–715 A).

These configurations ensure the cable can be customized for specific crane setups, balancing power delivery and data communication needs.

Benefits of TROMMELFLEX (KSM-S)

The TROMMELFLEX KSM-S offers several advantages that make it a preferred choice for E-RTG applications:

Unmatched Durability: The abrasion-resistant outer sheath and robust reinforcement withstand continuous mechanical stress.

Dual Functionality: Integrated fiber optics eliminate the need for separate data cables, reducing installation complexity and costs.

High Flexibility: The Class 5 copper conductors and rubber compounds allow the cable to handle repeated bending and torsion without damage.

Environmental Resistance: UV, oil, and flame resistance ensure reliability in harsh conditions, such as South Africa’s mining environments.

Long-Term Reliability: Designed for extended service life, reducing downtime and maintenance costs.

Safety Compliance: Meets international standards for fire and oil resistance, ensuring safe operation in industrial settings.

Usage Scenarios in South Africa

The TROMMELFLEX KSM-S is particularly relevant in South Africa, where the mining and port sectors are critical to the economy. Below are two use cases highlighting its application:

Case Study 1: Enhancing Efficiency in South African Ports

South Africa’s ports, such as the Port of Durban, handle significant cargo volumes, relying on E-RTG cranes for efficient container handling. In 2024, a major port operator upgraded its E-RTG fleet with TROMMELFLEX KSM-S cables. The cables’ integrated fiber optics enabled real-time data transmission for crane automation, reducing downtime by 15% and improving container throughput. The cables’ durability also minimized maintenance costs, crucial in a sector facing rising operational expenses due to global supply chain pressures.

Case Study 2: Supporting South Africa’s Mining Industry

In the platinum mines of the Bushveld Complex, E-RTG cranes are used for material handling in harsh, dusty environments. A leading mining company adopted TROMMELFLEX KSM-S cables in 2025 to replace outdated systems prone to frequent failures. The cables’ oil and abrasion resistance ensured reliable performance despite exposure to chemicals and mechanical stress. This upgrade reduced unplanned downtime by 20%, boosting productivity and aligning with South Africa’s push for sustainable mining practices.

Comparative Advantages

Compared to standard reeling cables, the TROMMELFLEX KSM-S offers:

Superior Durability: Its 5GM5 outer sheath outperforms standard PVC or PUR cables in abrasion resistance.

Integrated Data Transmission: Eliminates the need for separate fiber optic cables, reducing costs and complexity.

High Current Capacity: Supports up to 715 A, suitable for heavy-duty applications.

Environmental Resilience: Performs reliably in South Africa’s extreme climates, from coastal humidity to inland heat.

Frequently Asked Questions (FAQ)

Q1: What makes the TROMMELFLEX KSM-S suitable for E-RTG cranes?

A: Its combination of flexible copper conductors, durable rubber sheathing, and integrated fiber optics ensures reliable power and data transmission under high mechanical stress.

Q2: Can the cable operate in South Africa’s harsh climates?

A: Yes, it is designed for temperatures from -40°C to +80°C and is resistant to UV rays, oil, and flames, making it ideal for South Africa’s mining and port environments.

Q3: How does the fiber optic integration benefit crane operations?

A: The fiber optics enable high-speed, low-attenuation data transmission, supporting real-time monitoring and automation, which enhances operational efficiency.

Q4: What are the key installation considerations?

A: Maintain a minimum bending radius of 20 x cable diameter, avoid sharp bends, and use tension monitoring to prevent mechanical stress.

Q5: How does the TROMMELFLEX KSM-S compare to standard cables?

A: It offers superior durability, integrated data capabilities, and higher current-carrying capacity, making it a cost-effective, long-term solution.

Feichun TROMMELFLEX (KSM-S) (N)SHTOEU low voltage reeling cable is a game-changer for E-RTG cranes in South Africa’s mining and port industries. Its advanced design, combining robust power delivery with integrated fiber optics, addresses the challenges of high-stress industrial environments. With exceptional durability, flexibility, and compliance with international standards, this cable ensures reliable performance, reduced downtime, and enhanced operational efficiency. Whether in the dusty mines of the Bushveld or the bustling ports of Durban, the TROMMELFLEX KSM-S is a trusted solution for modern industrial demands.

For more details, consult Feichun’s technical data sheets or contact their support team to explore how this cable can elevate your operations.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430