Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Two-core 600/1000V cables with stranded copper conductors

APPLICATION

These power and control cables are used for electricity supply in low voltage installation system. They are well adapted to underground use in industrial applications where chemical and mechanical protections are needed (refinery areas, chemical plant...).

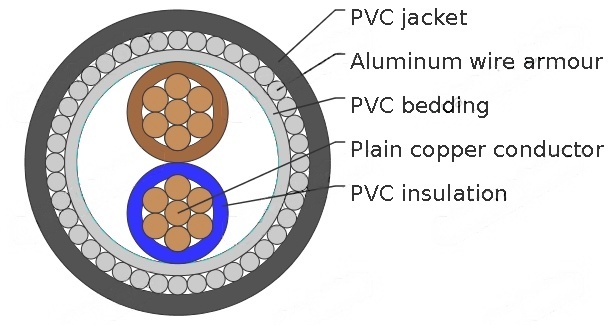

CONSTRUCTION

Conductor | Solid Aluminum or Copper conductor, round stranded or shaped, Class 2 to BS 6460, IEC 60228. |

Insulation | PVC(Polyvinyl Chloride) type TI1 |

Colour Code | 1 Core : Brown |

2 Cores : Brown or Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green-yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Filler(optional) | PVC or Polypropylene yarn |

Binder Tape(optional) | Polyester (Mylar) tape |

Inner Sheath/Bedding | PVC (Polyvinyl Chloride) |

Armour | Single Core : AWA (Aluminum Wire Armour) |

Multi Core : SWA (Steel Wire or Tape Armour) | |

Outer Sheath | PVC(Polyvinyl Chloride), type TM1 |

TECHNICAL INFORMATION

Voltage rating | 600/1000V |

Temperature rating | -20°C to +60°C |

Bending radius | Single core : 10 x overall diameter |

Multicores : 8 x overall diameter | |

Flame retardant | IEC60332 part 1, BS4066 part 1 |

CABLE PARAMETER

Nominal cross-sectional area | Number/wire | Nominal insulation thickness | Nominal bedding thickness | Nominal wire armor dia. | Nominal sheath thickness | Approx. overall diameter | Approx.cable weight | |

|---|---|---|---|---|---|---|---|---|

extruded bedding | taped bedding | |||||||

mm² | No./mm | mm | mm | mm | mm | mm | mm | kg/km |

7/0.53 | 0.6 | 0.8 | 0.9 | 1.4 | 12.3 | - | 270 | |

7/0.67 | 0.7 | 0.8 | 0.9 | 1.4 | 13.6 | - | 350 | |

7/0.85 | 0.8 | 0.8 | 0.9 | 1.4 | 15.1 | - | 470 | |

7/1.04 | 0.8 | 0.8 | 0.9 | 1.5 | 16.5 | - | 580 | |

7/1.35 | 1.0 | 0.8 | 1.25 | 1.6 | 20.1 | - | 840 | |

7/1.70 | 1.0 | 0.8 | 1.25 | 1.6 | 21.9 | 21.9 | 990 | |

7/2.14 | 1.2 | 1.0 | 1.6 | 1.7 | 26.7 | 26.3 | 1480 | |

7/2.14 | 1.2 | 1.0 | 1.6 | 1.7 | 23.0 | 22.6 | 1480 | |

19/1.53 | 1.2 | 1.0 | 1.6 | 1.8 | 29.2 | 28.8 | 1770 | |

19/1.53 | 1.2 | 1.0 | 1.6 | 1.8 | 24.8 | 24.4 | 1770 | |

19/1.78 | 1.4 | 1.0 | 1.6 | 1.9 | 27.8 | 27.4 | 1900 | |

19/2.14 | 1.4 | 1.0 | 1.6 | 1.9 | 30.4 | 30.0 | 2430 | |

19/2.52 | 1.6 | 1.2 | 2.0 | 2.1 | 35.5 | 34.7 | 2970 | |

37/2.03 | 1.6 | 1.2 | 2.0 | 2.2 | 38.0 | 37.2 | 3970 | |

37/2.25 | 1.8 | 1.2 | 2.0 | 2.3 | 41.3 | 40.5 | 4700 | |

37/2.52 | 2.0 | 1.4 | 2.5 | 2.4 | 46.4 | 45.2 | 5990 | |

61/2.25 | 2.2 | 1.4 | 2.5 | 2.5 | 51.2 | 50.0 | 7420 | |

61/2.52 | 2.4 | 1.6 | 2.5 | 2.7 | 56.4 | 54.8 | 8950 | |

61/2.85 | 2.6 | 1.6 | 2.5 | 2.9 | 61.9 | 60.3 | 11030 | |

*Shaped stranded conductor (class 2)

Introduction: Powering the Heart of Industry

Have you ever wondered what keeps the lights on and machines humming in South Africa's vast refineries, chemical plants, and mining operations? Beneath the surface – quite literally in many cases – lies a network of robust cables designed to withstand the rigours of industrial life. Among these, two-core 600/1000V armoured cables with stranded copper conductors stand out as unsung heroes. These cables, rated for low-voltage power supply, are engineered for reliability in environments where mechanical stress, chemical exposure, and underground installation are the norm.

What Are Two-Core 600/1000V Armoured Cables?

At their core (pun intended), two-core 600/1000V armoured cables are designed for electricity supply in low-voltage systems, typically up to 1000 volts. The "two-core" designation means they consist of two insulated conductors – usually one for live and one for neutral – encased in protective layers. These cables are particularly suited for underground use in industrial applications where protection against chemicals and mechanical damage is crucial, such as in refinery areas or chemical plants.

The voltage rating of 600/1000V indicates they can handle 600 volts between conductors and 1000 volts to earth, making them ideal for power and control circuits in fixed installations. Unlike unarmoured cables, these feature a layer of steel wire armour (SWA) for multi-core variants, providing extra defence against impacts, rodents, and soil pressure. In South Africa, they must comply with standards like SANS 1507, which governs low-voltage PVC and XLPE insulated cables, ensuring safety and performance in local conditions.

Imagine these cables as the veins of an industrial body: they carry the lifeblood of electricity, but they're built tough to survive the harsh realities of buried trenches or exposed conduits. Their popularity stems from a balance of cost-effectiveness, durability, and ease of installation, especially in Africa's variable climates.

The Power of Stranded Copper Conductors

Why stranded copper? Copper's excellent conductivity – second only to silver – minimises power loss, conserving energy in long runs typical of industrial setups. Stranded versions offer key advantages over solid: higher flexibility reduces fatigue in vibrating environments like pumps or conveyors, and they handle repetitive motion better without fracturing. However, stranding introduces slight air gaps, increasing DC resistance by up to 5-10% compared to solid, though this is negligible in low-voltage AC applications.

Round vs. shaped stranding: Round is simpler and more flexible for smaller cables, ideal for general wiring. Shaped stranding, used in larger cross-sections (e.g., 2x50* mm²), compacts the conductor, reducing cable diameter and weight while maintaining ampacity. For instance, a 2x25 mm² round cable might have a 26.7 mm diameter, but shaped drops to 23.0 mm, easing pulls through conduits. This is crucial in space-constrained South African mines, where smaller cables mean less excavation.

Looking at parameters: Nominal cross-sections range from 2x1.5 mm² (7/0.53 strands, 12.3 mm diameter, 270 kg/km) to 2x400 mm² (61/2.85 strands, 61.9 mm diameter, 11,030 kg/km). Larger sizes use more strands (e.g., 61 for 300 mm²) for flexibility. Insulation thickness increases with size – 0.6 mm for 1.5 mm² to 2.6 mm for 400 mm² – to handle higher currents safely.

In terms of performance, stranded copper excels in skin effect mitigation at higher frequencies, though less relevant here. Overall, these conductors balance conductivity, durability, and cost, making them a staple in 600/1000V systems.

Applications: From Mines to Manufacturing

In South Africa, these cables power everything from conveyor belts in platinum mines to pumps in petrochemical refineries. Their armoured design suits underground burial, protecting against soil acids and mechanical digs. For example, in Sasol's Secunda complex, they supply control circuits in chemical-laden areas.

They're also used indoors/outdoors per BS 5467 (harmonised with SANS), in ducts or trays. With flame-retardant properties, they're safe for fire-prone sites. In renewable energy, like solar farms in the Northern Cape, they connect inverters at low voltages.

Conclusion: The Future Wired in Reliability

So, why are two-core 600/1000V armoured cables with stranded copper conductors essential? They embody resilience, efficiency, and adaptability, powering South Africa's industrial might while meeting stringent standards. As the nation electrifies rural areas and expands renewables, these cables will remain foundational. Understanding their intricacies not only demystifies technology but empowers better decisions in a power-hungry world.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430