Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Two-core 600/1000V cables with stranded copper conductors

APPLICATION

These cables are used for power and control circuits, they can offer excellent protection through the use of a heavy galvanized steel wire armour. The GSWA makes them suitable for use inside and outside buildings or for direct burial in the ground. For installation where fire, smoke emission and toxic fumes create a potential threat to life and equipment.

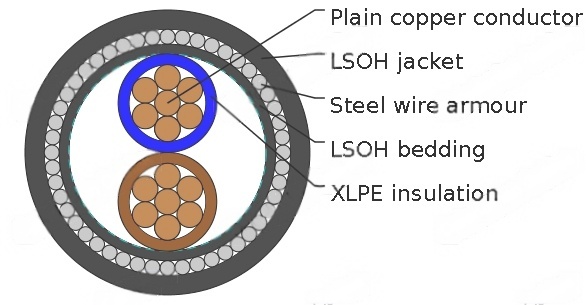

CONSTRUCTION

Conductor | Solid Aluminum or Annealed Copper conductor, circular or shaped, Class 2 to BS EN60228. |

Insulation | XLPE (Cross-Linked Polyethylene) Type GP 8 conforming to BS 7655-1.3 or type GP 6 conforming to BS 7655-1.2. |

Colour Code | 1 Core : Brown or Blue |

2 Cores : Brown, Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green/Yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Bedding | The bedding shall consist of an extruded layer of polymeric material consistent with the operating temperature of the cable. |

Armour | Single Core : AWA (Aluminum Wire Armour) |

Multi Core : GSWA (Galvanized Steel Wire Armour) | |

Outer Sheath | LSOH (Low Smoke Zero Halogen),conforming to BS 7655-6.1. |

TECHNICAL INFORMATION

Voltage rating | 600/1000V |

Temperature rating | 0°C to +90°C |

Min. Bending radius | 8 x overall diameter |

Flame retardant | BS EN 60332-1-2 ; BS EN 60332-3-24:2009 |

Halogen free | BS EN 60754-1 |

Smoke density | BS EN 61034-2 |

CABLE PARAMETER

Nominal Cross-sectional Area | Strand Type | Nominal Insulation Thickness | Nominal BeddingThickness | Nominal Steel Wire Armor dia. | Nominal Sheath Thickness | Approx. Overall Diameter | Aprrox. Weight |

|---|---|---|---|---|---|---|---|

mm² | No./mm | mm | mm | mm | mm | mm | kg/km |

7/0.53 | 0.6 | 0.8 | 0.9 | 1.4 | 12.1 | 320 | |

7/0.67 | 0.7 | 0.8 | 0.9 | 1.4 | 13.6 | 365 | |

7/0.85 | 0.7 | 0.8 | 0.9 | 1.4 | 14.7 | 440 | |

7/1.04 | 0.7 | 0.8 | 0.9 | 1.4 | 15.9 | 470 | |

7/1.35 | 0.7 | 0.8 | 0.9 | 1.5 | 18.0 | 800 | |

7/1.70 | 0.7 | 0.8 | 1.25 | 1.5 | 20.4 | 900 | |

7/2.14 | 0.9 | 0.8 | 1.25 | 1.6 | 24.1 | 1240 | |

7/2.14 | 0.9 | 0.8 | 1.25 | 1.6 | 20.4 | 1240 | |

7/2.52 | 0.9 | 1 | 1.6 | 1.7 | 27.7 | 1710 | |

7/2.52 | 0.9 | 1 | 1.6 | 1.7 | 23.3 | 1710 | |

19/1.78 | 1.0 | 1 | 1.6 | 1.8 | 25.8 | 1800 | |

19/2.14 | 1.1 | 1 | 1.6 | 1.9 | 29.0 | 2320 | |

19/2.52 | 1.1 | 1.2 | 2.0 | 2.0 | 33.0 | 3150 | |

37/2.03 | 1.2 | 1.2 | 2.0 | 2.1 | 36.1 | 3880 | |

37/2.25 | 1.4 | 1.2 | 2.0 | 2.2 | 39.3 | 4820 | |

37/2.52 | 1.6 | 1.4 | 2.5 | 2.4 | 44.7 | 5920 | |

61/2.25 | 1.7 | 1.4 | 2.5 | 2.5 | 49.0 | 7300 | |

61/2.52 | 1.8 | 1.6 | 2.5 | 2.6 | 53.5 | 8770 | |

61/2.85 | 2 | 1.6 | 2.5 | 2.8 | 59.0 | 10905 |

* D-Shaped stranded conductor (class 2)

What Are Two-Core Armoured Cables?

At their core—no pun intended—two-core armoured cables are designed for transmitting electrical power efficiently while providing robust protection against environmental and mechanical stresses. These cables typically consist of two conductors, making them ideal for single-phase power supplies or control circuits where simplicity and reliability are key. Rated at 600/1000V, they handle low-voltage applications common in buildings, industrial sites, and underground installations.

The "armoured" aspect refers to a layer of galvanised steel wire armour (GSWA) that encases the inner components, offering superior defence compared to unarmoured alternatives. This design is particularly suited for South African contexts, where diverse climates—from the arid Karoo to humid coastal regions—demand durable infrastructure. According to cable manufacturers, such cables are engineered to BS EN standards, ensuring compliance with international safety norms.

Two-core configurations are straightforward: one conductor for live (usually brown) and one for neutral (blue), as per standard colour coding. This simplicity reduces installation errors, a common issue in electrical work. But to truly appreciate their value, we must peel back the layers—literally—and examine their construction.

The Power of Stranded Copper Conductors

Stranded copper conductors are the unsung heroes of these cables. Unlike solid conductors, which are a single piece of metal, stranded versions bundle multiple thinner wires. This design offers several advantages, particularly in flexibility and durability.

First, flexibility: Stranded wires can bend and twist without breaking, making them perfect for installations involving curves or vibrations, such as in mining operations in Rustenburg or wind farms in the Eastern Cape. Solid wires, by contrast, are prone to fatigue and cracking under repeated movement.

Second, resistance to metal fatigue: The multiple strands distribute stress, extending the cable's lifespan in dynamic environments. Studies show stranded cables withstand millions of flex cycles before failure, far outperforming solids.

Third, electrical performance: While copper's high conductivity (better than aluminium) ensures low resistance, stranding increases surface area, mitigating the skin effect in AC currents where electricity flows on the wire's exterior. This results in efficient power transmission with less heat generation.

In two-core setups, stranded copper also aids in heat dissipation, as air gaps between strands allow better cooling. For South African users, where load shedding strains systems, this means fewer overload risks. However, stranding slightly increases cost and diameter compared to solid, a trade-off justified by enhanced reliability.

Applications:

These cables excel in power and control circuits, offering protection for indoor, outdoor, and direct burial uses. In buildings, they're used for lighting and appliance feeds; outdoors, for street lighting or garden supplies; and underground, for connecting substations in Pretoria's grid.

Their armour allows direct burial without conduits, saving costs in rural electrification projects. LSOH sheathing makes them suitable for hospitals, schools, and tunnels where fire safety is paramount, as seen in Gautrain infrastructure.

So, why are two-core armoured cables essential? They combine stranded copper's flexibility, XLPE's resilience, and GSWA's protection to deliver safe, efficient power while addressing common pitfalls like damage and overheating. In South Africa, where reliable electricity is vital for growth, investing in such cables ensures longevity and safety. Whether for home renovations or large-scale projects, these unsung heroes keep the lights on—literally.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430