Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

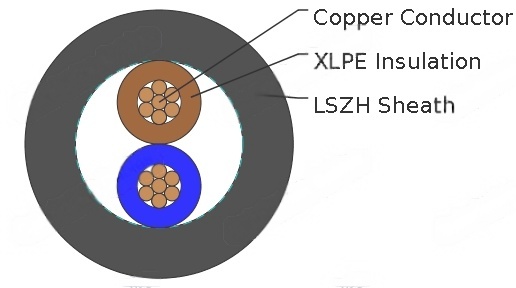

Two-core 600/1000V XLPE Insulation, LSZH Sheath Cables to BS 8573

Application

These XLPE insulated and LSZH sheathed cables are generally used for fixed installation. Suitable for building wiring, especially in areas where smoke and fume emissions may cause a potential threat to life but not for burial in the ground, either directly or in ducts.

Standard

Basic design to BS 8573:2012

Fire Performance

Flame Retardance (Single Vertical Wire Test) | BS EN 60332-1-2:2004 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) | BS EN 60332-3-24:2009 (cat. C) |

Halogen Free | BS EN 50267-2-1 |

Minimum Smoke Emission | BS EN 61034-2 |

Spark Test | BS EN 62230 |

Voltage Rating

600/1000V

Construction

Conductor : Annealed copper conductor, strand according to BS EN 60228 class 2.

Insulation : XLPE type GP8 according to BS 7655-1.3. HEPR type GP6 according to BS 7655-1.2, or crosslinked polyolefin material type EI 5 according to BS EN 50363-5 can be offered as option.

Inner Covering option : The laid up cores may be coverd by an optional extrued inner covering or separating tape. It shall be possible to separate the cores easily.

Outer Sheath : Thermoplastic LSZH type LTS 4 according to BS 7655-6.1.

Outer Sheath option : UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option.

Color Code

Insulation Colour : Brown and blue

Sheath Colour : Black, other colours can be offered upon request.

Physical And Thermal Properties

Maximum temperature range during operation (XLPE) : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius:

Circular copper conductors(up to 25mm²) : 4 x Overall Diameter

Circular copper conductors(above 25mm²) : 6 x Overall Diameter

Shaped copper conductors : 8 x Overall Diameter

Construction Parameters

Conductor | Nominal Insulation Thickness | Nominal Inner Covering Thickness | Nominal Sheath Thickness | |

|---|---|---|---|---|

No. of Cores x Cross Section | Class of Conductor | |||

No. x mm² |

| mm | mm | mm |

2 | 0.7 | 0.4 | 1.8 | |

2 | 0.7 | 0.4 | 1.8 | |

2 | 0.7 | 0.4 | 1.8 | |

2 | 0.7 | 0.4 | 1.8 | |

2 | 0.7 | 0.6 | 1.8 | |

2 | 0.7 | 0.6 | 1.8 | |

2 | 0.9 | 0.8 | 1.8 | |

2 | 0.9 | 0.8 | 1.8 | |

2 | 1.0 | 1.0 | 1.8 | |

2 | 1.1 | 1.0 | 1.8 | |

2 | 1.1 | 1.2 | 1.9 | |

2 | 1.2 | 1.2 | 2.0 | |

2 | 0.9 | 0.6 | 1.8 | |

2 | 0.9 | 0.6 | 1.8 | |

2 | 1.0 | 0.8 | 1.8 | |

2 | 1.1 | 0.8 | 1.8 | |

2 | 1.1 | 1.0 | 1.9 | |

2 | 1.2 | 1.0 | 2.0 | |

Understanding BS 8573:2012 – The Foundation Standard

BS 8573:2012 is a British Standard that outlines requirements for thermosetting insulated, non-armoured cables rated at 600/1000V, specifically designed for fixed installations with low smoke and corrosive gas emissions. Published by the British Standards Institution (BSI), it emphasises cables that minimise hazards during fires, aligning with international norms like IEC 60502 for power cables. In South Africa, while local standards such as SANS 10142 (The Wiring of Premises) govern installations, BS 8573-compliant cables are often imported or manufactured locally to meet global benchmarks, especially in high-risk sectors like mining and commercial buildings.

The standard specifies flame retardance, reduced fire propagation, halogen-free composition, and minimal smoke emission, tested under protocols like BS EN 60332-1-2 for single vertical wire tests and BS EN 60332-3-24 for bundled cables. This ensures the cables do not contribute to fire spread or toxic environments, a critical factor in densely populated structures. For two-core variants, the standard accommodates cross-sections from 1.5 mm² to 120 mm², catering to various load requirements in building wiring.

Fire Performance and Safety Analysis

Fire safety is a cornerstone of these cables' design. Compliant with BS EN 60332-1-2 for flame retardance and BS EN 60332-3-24 (Category C) for reduced propagation, they limit fire spread in vertical bundles. Halogen-free per BS EN 50267-2-1, LSZH sheaths emit minimal smoke (BS EN 61034-2) and no corrosive gases, reducing visibility impairment and acid damage to equipment during fires.

In scientific terms, halogens in traditional cables release hydrogen chloride gas when burning, forming hydrochloric acid that corrodes metals and irritates respiratory systems. LSZH, by contrast, produces water vapour and carbon dioxide, enhancing escape times in fires – a benefit proven in studies showing up to 50% less smoke density. Spark testing to BS EN 62230 ensures insulation integrity, preventing arc faults. In South African contexts, where building fires claim hundreds of lives annually, these features align with SANS 10400 fire regulations.

Applications in Building Wiring

Primarily for fixed installations in buildings, these cables excel in areas sensitive to smoke, such as hospitals, schools, and high-rises, but not for direct burial. In South Africa, they're used in commercial wiring, power stations, and mass transit systems, supporting loads from lighting (1.5-4 mm²) to heavy appliances (up to 120 mm²). Their non-armoured nature suits indoor containment like conduits or trays, per SANS 10142.

Advantages Over Traditional PVC-Insulated Cables

Compared to PVC, XLPE-LSZH cables offer longer service life (up to 40-50 years vs. 20-30), higher temperature tolerance, and better environmental resistance. PVC melts at lower temperatures, dripping and propagating fire, while XLPE maintains form. LSZH reduces toxicity, making it preferable in confined spaces. However, they may cost 20-30% more, though savings in maintenance and safety justify this.

Environmental Impact and Sustainability

LSZH cables minimise environmental harm by avoiding halogen release, reducing acid rain contributions and soil contamination during disposal. Their recyclability supports South Africa's circular economy goals, with lower carbon footprints in production compared to PVC. In fire scenarios, they limit pollutant emissions, aiding compliance with environmental regulations.

Installation Considerations

Installation follows SANS 10198 guidelines, with careful bending to avoid stress. Use cleats for support, and ensure compatibility with accessories. Professional certification is mandatory under South African law.

FAQs

What does XLPE stand for, and why is it used? XLPE is cross-linked polyethylene, chosen for its heat resistance and durability.

Are these cables suitable for outdoor use? Primarily indoor, but with UV-resistant options, they can be adapted.

How do LSZH cables improve fire safety? They produce low smoke and no halogens, enhancing visibility and reducing toxicity.

What is the voltage rating? 600/1000V, ideal for building power distribution.

Can they be buried? No, not directly; they're for above-ground fixed installations.

Two-core 600/1000V XLPE insulated LSZH sheathed cables to BS 8573 represent a pinnacle of safe, efficient wiring technology. Their multifaceted advantages – from superior thermal properties to environmental benefits – make them indispensable in modern buildings, particularly in fire-vulnerable South African urban landscapes. As regulations evolve, adopting these cables ensures compliance, safety, and sustainability for generations to come.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430