Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type 1 1.1/1.1KV Collectively Screened to AS/NZS 1972/1125/3808

Type 1 Mining Machine Cable: Essential Solutions for Mining Equipment Power Requirements, Drills, and Drilling Equipment in Harsh Industrial Environments

Type 1 1.1/1.1KV Collectively Screened to AS/NZS 1972/1125/3808

Applications | These collectively copper screened cables are used for wiring of machines, or between machines and equipment where PVC is suitable. |

Standards | AS/NZS 1972:2006 |

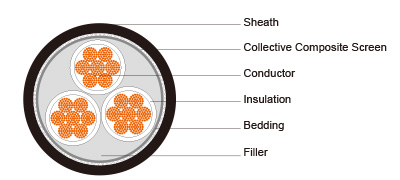

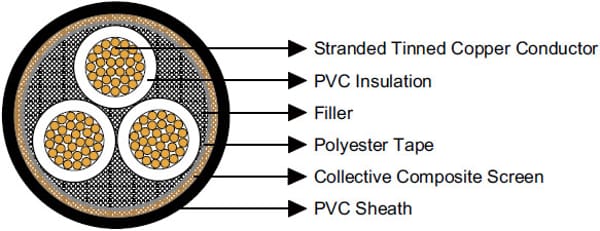

Construction  | |

Conductors | Stranded copper conductor. |

Insulation | PVC. |

Bedding | Polyester tape. |

Individual Composite Screen (earth conductor) | Tinned annealed copper braiding interwove with polyester yarn. |

Sheath | PVC sheath. |

Dimensions and Weight

Number of Cores | Nominal Conductor Area | Strand Size | Insulation Thickness | Core screen | Thickness of Sheath | Nominal Overall Diameter | Nominal Weight | |

Strand Size | Area of Screen | |||||||

| mm² | No/mm | mm | mm | mm² | mm | mm | kg/100m |

Type 1 – Collectively Screened | ||||||||

2 | 1.5 | 30/0.25 | 0.8 | 0.20 | 2.3 | 0.8 | 9.2 | 12 |

3 | 1.5 | 30/0.25 | 0.8 | 0.20 | 2.5 | 0.8 | 9.7 | 15 |

4 | 1.5 | 30/0.25 | 0.8 | 0.20 | 2.6 | 0.8 | 10.5 | 18 |

6 | 1.5 | 30/0.25 | 0.8 | 0.20 | 3.4 | 0.8 | 12.6 | 25 |

16 | 1.5 | 30/0.25 | 0.8 | 0.20 | 5.1 | 1.0 | 18.7 | 55 |

30 | 1.5 | 30/0.25 | 0.8 | 0.25 | 8.8 | 1.3 | 24.6 | 96 |

Benefits: Why Type 1 Stands Out in Mining Operations

The Type 1 Mining Machine Cable offers a suite of benefits that directly address mining challenges. Foremost is its durability: Engineered for harsh environments, it resists dust, moisture, and mechanical stress, extending lifespan and reducing replacement costs. In South Africa's declining precious metals sector, where ESG pressures demand sustainable practices, this longevity minimizes waste and environmental impact.

High-temperature resistance up to 90°C ensures reliable performance in deep underground mines or open-pit operations under the African sun. For drills and drilling equipment, this means uninterrupted power, preventing costly halts during exploration for critical minerals like platinum group metals (PGMs), which are seeing renewed demand due to renewable energy transitions.

The separate copper shield provides superior EMI protection, safeguarding sensitive electronics in modern electric drills. This is especially beneficial in electrified mining trends, where equipment shifts from diesel to electric to cut emissions and costs. Additionally, its tension resistance handles taut installations over long distances, ideal for interconnecting devices in sprawling mine layouts.

Safety is enhanced through standards compliance, reducing risks of electrical fires or shocks—critical in an industry plagued by safety concerns. Economically, it boosts efficiency by minimizing downtime, aligning with calls for cost-cutting and profitability. Customizability allows tailoring to specific needs, such as added shielding for EMI-heavy zones.

Usage Scenarios: From Drills to Interconnections

The Type 1 Mining Machine Cable shines in fixed applications like powering stationary drills in exploration phases or interconnecting control systems in processing plants. In underground mining, it's used for permanent power lines to drilling equipment, where high temperatures and EMI are prevalent.

In open-pit scenarios, it connects generators to machinery, enduring sun exposure and tension. For South African contexts, amid infrastructure issues, it's vital for backup power systems during load shedding.

FAQ: Addressing Common Queries

What is the primary use of the Type 1 Mining Machine Cable? It's mainly for powering drills, drilling equipment, and fixed interconnections in mining, where PVC suits and mechanical strength is needed.

Can it withstand high temperatures? Yes, up to 90°C, ideal for demanding environments.

Is it suitable for fixed installations? Absolutely, its design ensures durability for permanent setups.

Does it comply with standards? Yes, meeting AS/NZS and IEC standards for safety and performance.

Can it be customized? Yes, for length, shielding, and features to fit specific mining needs.

The Type 1 Mining Machine Cable is a cornerstone for reliable mining equipment power requirements, drills, and drilling equipment. As South Africa's mining sector navigates 2025's challenges—from energy crises to sustainability—investing in such technology ensures resilience and progress.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430