Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type 241 Superflex 1.1 to 6.6KV Mining Cable AS/NZS 1802

Type 241SF cable has special stranding and lay-up. PED ratio to provide maximum flexibility in arduous conditions. General purpose cable for continuous miners, or feeder cables to pumps. Also commonly used for monorails supplying DCBs and longwalls.

Applications

These cablesare similar to Type 241 cables, except more flexible and have a smaller ‘natural’ bending radius, suitable for use as monorail cable where cable loops will be narrower, thus allowing more space for other equipmentand reducing opportunities for getting snagged.

Standards

AS/NZS 1802:2003

AS/NZS 1125

AS/NZS 3808

AS/NZS 5000.1

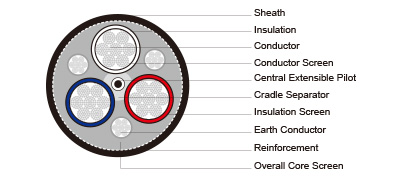

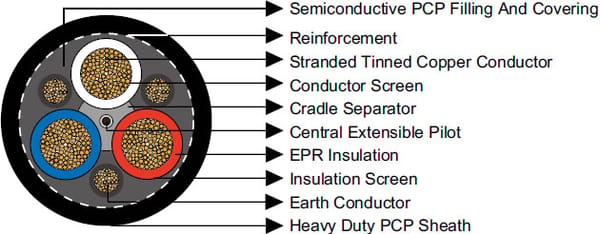

Construction

3×Conductors: Flexible stranded tinned annealed copper conductor.

Conductor Screen: 1.1/1.1kV - polyester barrier tape, 3.3/3.3kV andabove - polyester barrier tape and extruded semiconductive tape.

Insulation: EPR.

Insulation Screen:Semiconductive tape.

Cradle Separator: Semiconductive PCP.

Overall Core Screen: SemiconductivePCP filling andcovering.

3×Interstitial Earth Conductor: Semiconductive PCP insulated flexible stranded tinned copper conductor.

1×Central Extensible Pilot:EPR covered flexible stranded tinned copper conductor.

Textile Reinforcement: Open-weave braid reinforcement.

Sheath: Heavy duty PCP sheath.

The Type 241 Superflex Mining Cable is designed for versatility and durability, making it suitable for various mining applications. Below are its key use cases:

Open-Pit Mining Operations

Environment: Dynamic, with equipment constantly in motion.

Cable Requirements: High flexibility and durability to keep up with moving machinery.

Applications: Powers large shovels, drills, and conveyors in surface mining.

Benefits: Handles the rigorous demands of open-pit environments, ensuring reliable performance.

Draglines and Shovels

Equipment Demands: Heavy mechanical stress and continuous movement.

Cable Requirements: Robust construction to withstand intense operational conditions.

Applications: Provides consistent power delivery for draglines and shovels.

Benefits: Maintains reliability under daily operational rigors.

Haul Trucks and Other Mobile Equipment

Equipment Needs: Cables that move with machinery and resist wear from constant use.

Cable Requirements: Flexibility combined with high durability.

Applications: Powers haul trucks and other mobile mining equipment.

Benefits: Ensures uninterrupted operation by delivering dependable power.

Portable Power Solutions

Use Case: Temporary or remote power setups in mining operations.

Cable Requirements: Flexible and durable for easy deployment and reliability.

Applications: Supports equipment at remote locations or temporary mining sites.

Benefits: Provides consistent power delivery wherever needed.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430