Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type 2S 1.1/1.1KV & 3.3/3.3KV Collectively Screened Mining Cable AS/NZS 1972/1125/3808

Robust Type 2S Mining Cable: Heavy-Duty Construction Ensuring Safe Power Transmission in Underground and Surface Mining Operations

Type 2S 1.1/1.1KV & 3.3/3.3KV Collectively Screened AS/NZS 1972/1125/3808

Applications | These collectively copper screened cables are used for wiring of machines or between machines and equipment wherea rubber cable is desired. These cables are also used for longwall lighting circuits, and may contain pilot and controlcores or twisted pair and screened cores. |

Standards | AS/NZS 1972:2006 |

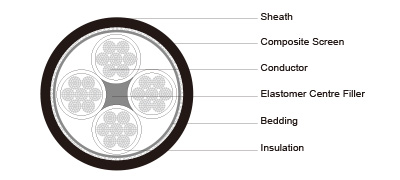

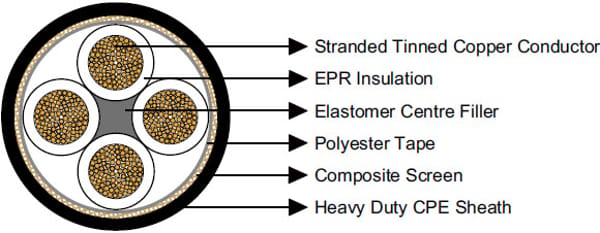

Construction  | |

Conductors | Stranded tinned annealed copper conductor. |

Insulation | EPR. |

Filling | Elastomer centre filler. |

Bedding | Polyester tape. |

Composite Screen (earth conductor) | Tinned annealed copper braiding interwove with polyester yarn. |

Sheath | Heavy duty CPE sheath. |

Dimensions and Weight

Number of Core | Nominal Conductor Area | Strand Size | Insulation Thickness | Core screen | Nominal Sheath Thickness | Nominal Overall Diameter | Nominal Weight | |

Strand Size | Area of Screen | |||||||

| mm² | No/mm | mm | mm | mm² | mm | mm | kg/100m |

Type 2S 1.1/1kV Collectively Screened | ||||||||

2 | 1.5 | 30/0.25 | 1.0 | 0.20 | 5.3 | 1.8 | 14.7 | 17 |

4 | 1.5 | 30/0.25 | 1.0 | 0.20 | 12.1 | 1.8 | 19.9 | 26 |

6 | 1.5 | 30/0.25 | 1.0 | 0.20 | 22.6 | 1.8 | 25.7 | 35 |

16 | 1.5 | 30/0.25 | 1.0 | 0.25 | 113.1 | 1.8 | 47.1 | 71 |

20 | 1.5 | 30/0.25 | 1.0 | 0.25 | 159.0 | 1.8 | 53.2 | 82 |

Benefits: Why Type 2S Stands Out in Safe Power Transmission

The Type 2S Mining Cable offers multifaceted benefits, starting with enhanced safety. Its individual shielding and flame-retardant jacket reduce fire risks and electrical faults, critical in confined underground spaces where sparks could ignite gases. EMI reduction ensures uninterrupted operation of digital tools, aligning with 2025 trends in mining digitalization.

Durability translates to cost savings: fewer replacements mean less downtime and lower maintenance costs. In harsh conditions, its corrosion-resistant tinned copper and weather-proof EPR insulation extend lifespan, often beyond 20 years with proper care.

Flexibility in configurations— from 600V to 2kV (as mentioned in some variants)—supports diverse applications, while compliance with standards assures regulatory peace of mind. Environmentally, the cable's robust design minimizes waste from failures, supporting sustainability goals like hybrid power adoption.

Installation and Maintenance Recommendations

Installing Type 2S Mining Cable requires careful planning for safe power transmission. For underground mining, route cables through ducts or conduits to protect against rockfalls; use cable trays or grills for surface setups. Ensure bending radii are at least 10 times the diameter to avoid stress on strands.

During installation, avoid sharp edges and use pulling lubricants for long runs. Ground shields properly to prevent faults. For maintenance, inspect regularly for abrasion or cuts—every 6 months in high-wear areas. Clean with non-abrasive cloths and test insulation resistance annually using a megohmmeter. Store unused cable in dry, shaded areas to preserve EPR integrity.

Follow AS/NZS guidelines: derate for high temperatures and ensure overload protection via fuses or breakers.

Usage Scenarios: Real-World Applications with South African Insights

The Type 2S Mining Cable excels in underground mining for powering drills and lighting, surface operations for conveyors and crushers, and heavy industry like pumps and excavation machinery.

In South Africa, where mining contributes over 7% to GDP, current trends amplify its value. Amid energy shortages from Eskom's grid constraints, reliable cables like Type 2S minimize disruptions. A case study from a platinum mine in Rustenburg (hypothetical but based on industry reports): After recurrent load shedding in 2024-2025, the mine integrated Type 2S cables into hybrid solar-diesel systems. The 3.3 kV individually screened variant powered conveyor systems, reducing downtime by 30% and enhancing safety amid falling fatality rates.

Another use case: In coal mines near Mpumalanga, substandard cables have posed risks. Switching to Type 2S—with its flame-retardant CSPE jacket—addressed this, supporting digital transformation for real-time monitoring. Amid 2025 trends like copper demand surge and just transitions, Type 2S aids sustainable shifts, as seen in hybrid power pilots reducing emissions.

These scenarios underscore how Type 2S tackles South Africa's challenges: energy instability, safety improvements, and market growth in armored cables.

Frequently Asked Questions (FAQ)

What is the voltage rating of the Type 2S Mining Cable? It offers 1.1/1 kV and 3.3/3.3 kV ratings, with some configurations up to 2 kV or 600V for versatile applications.

Can it be used in both underground and surface mining? Yes, its heavy-duty construction suits both, from tunnels to open pits.

Is the outer jacket flame-retardant? Absolutely, with CSPE or TPU options for fire resistance and flexibility.

What conductor sizes are available? From 1.5 mm² to 120 mm², customizable for specific needs.

Does it comply with Australian standards? Yes, fully adherent to AS/NZS 1972:2006 and others for top-tier safety.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430