Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

SANS Type 61A 0.64/1.1kV Flexible Copper Screened Mining Cable

Type 61A 0.64/1.1kV flexible copper screened mining cables: offering superior durability, safety, and resistance to environmental hazards while addressing current trends like cable theft and power outages.

SANS Type 61A 0.64/1.1kV Flexible Copper Screened Mining Cable

OVERVIEW:

Electrically driven machines , movable electric apparatus in hazardous areas .Not for reeling purposes.

Other industrial applications .

FEATURES:

Excellent flexibility

Water resistant and flame retardant Operating temperature min. ambient temp . -25 0C , max. conductor temp. 900C.

UV ,sunlight , ozone ,oil, resistant

Embossing marking as per order.

Specifications

Low Voltage

UV Resistance

Working Temperature 90℃

Cold Resistant -40℃

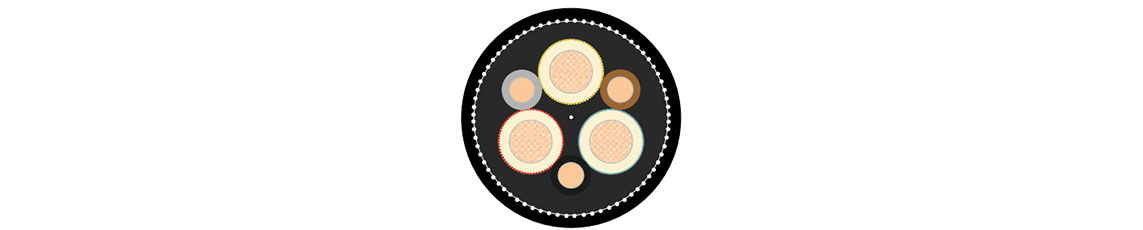

Construction

Cable type: Type 61A 0.64/1.1 kV

Conductors: Flexible class 5 comply to SANS 1411 - 1 from tinned annealed copper wires left lay with semi-conducting rubber screen .

Insulation: Ethylene propylene thermosetting compound type RD 3 comply to SANS 1411-3 and a strippable semi-conducting core screen (triple extruded)

Core of cable: Three tinned copper braided screened power cores and three unscreened pilot cores one in each interstice laid up in the right hand lay around semi-conductive cradle centre (only16 mm2 around rubber (RD1) filler centre ) .

Inner sheath: Poly-chloroprene thermosetting compound type RS 6 comply to SANS 1411-3 .

Re-enforcement: An open nylon braid . Minimum 16 of nylon strings .

Outer sheath: Poly-chloroprene thermosetting compound type RS 6 comply to SANS 1411-3 .

Colour of sheath: Black.

Tests: SANS 1520-1.

Parameter:

Type 61A 0.64/1.1kV Mining Cable

Physical Properties | ||||||||||

Power cores | ||||||||||

Conductor sizes (mm2) | 16 | 25 | 35 | 50 | 70 | 95 | 120 | 150 | ||

Maximum wire diameter ( mm) | 0.41 | 0.41 | 0.41 | 0.51 | 0.51 | 0.51 | 0.51 | 0.51 | ||

Approx. conductor diameter ( mm) | 5.3 | 6.8 | 8.5 | 10.3 | 11.9 | 13.5 | 15.5 | 17.3 | ||

Maximum screen wire diameter (mm) | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | ||

Braided screen filling factor (%) | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | ||

Approx. summarized screen cross-section for power cores | 22 | 25 | 27 | 32 | 37 | 43 | 47 | 52 | ||

Pilot Cores | ||||||||||

Conductor sizes ( mm2) | 10 | 10 | 16 | 16 | 16 | 16 | 16 | 16 | ||

Maximum wire diameter ( mm) | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 | ||

Approx. conductor diameter ( mm) | 4.2 | 4.2 | 5.3 | 5.3 | 5.3 | 5.3 | 5.3 | 5.3 | ||

Lay Ratio (maximum) (x PCD) | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | ||

Cable Diameter | ||||||||||

Approx. (mm) | 31 | 38 | 43 | 47 | 52 | 58 | 63 | 70 | ||

Cable mass (approx.) (kg/m) | 1.8 | 3.1 | 3.6 | 4.5 | 5.6 | 7.0 | 8.4 | 10.2 | ||

Minimum bending radius (mm) | 200 | 240 | 260 | 290 | 320 | 350 | 390 | 430 | ||

Maximum recommended tension (kN) | 0.7 | 1.1 | 1.6 | 2.3 | 3.2 | 4.3 | 5.4 | 6.8 | ||

Benefits of Type 61A Cables

Type 61A cables are designed for harsh mining environments, offering multiple advantages:

Flexibility: Reduces installation stress, enables easy routing in confined spaces, and minimizes fatigue over time.

Environmental Resistance:

Water Resistance: Prevents short circuits in flooded mines, critical in South Africa due to climate-induced heavy rains.

UV, Sunlight, Ozone, and Oil Resistance: Ensures durability in outdoor or chemically exposed settings.

Temperature Range: Operates reliably from -25°C to 90°C, suitable for South Africa’s variable climates (e.g., Highveld winters to Lowveld summers).

Safety Features:

Flame Retardancy: Complies with international safety standards, reducing fire risks in gas-prone areas.

Tinned Copper Construction: Resists corrosion for enhanced longevity.

Screened Design: Shields against electromagnetic interference and deters theft by making copper harder to access.

Operational Efficiency:

Energy Efficiency: Lowers resistance losses, reducing costs amid rising electricity prices.

Pilot Cores: Enable real-time monitoring to prevent overloads and extend equipment life.

Sustainability: Aligns with 2025 trends toward sustainable mining by boosting productivity, safety, and cost savings.

Installation Best Practices

To maximize performance and longevity:

Site Assessment: Match cable size to load requirements and avoid exceeding maximum tension or bending radius to prevent internal damage.

Support and Protection:

Use approved clamps/supports every 1-2 meters in vertical runs.

Protect against sharp edges with padding.

Underground Routing: Avoid high-traffic areas to minimize abrasion.

Connections: Use explosion-proof glands in hazardous zones.

Post-Installation Testing: Conduct continuity and insulation resistance tests to ensure reliability.

Maintenance Best Practices

To ensure a service life exceeding 10 years:

Regular Inspections: Check for cuts, swelling, or discoloration.

Cleaning: Use non-abrasive solvents.

Temperature Monitoring: Use infrared thermography to detect hotspots.

Theft Prevention: Integrate remote monitoring systems (e.g., Transnet’s satellite-based alerts).

Replacement and Storage:

Replace cables with 20% wear.

Store spares in dry, UV-protected areas.

Compliance: Follow SANS standards for all practices.

Usage Scenarios and Case Studies

Type 61A cables are versatile in demanding mining applications:

Underground Mining:

Power shuttle cars, continuous miners, and ventilation fans.

Open-Cast Mining:

Supply movable crushers and pumps, withstanding repeated flexing without failure.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430