Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

SANS Type 61B 0.64/1.1kV Flexible Copper Screened Mining Cable

Type 61B Copper Shield 0.64/1.1kV Mining Cable: Enhancing Safety, Reliability, and Efficiency in South Africa's Challenging Mining Landscape Under SANS 1520 Standards

SANS Type 61B 0.64/1.1kV Flexible Copper Screened Mining Cable

Applications

Electrically driven machines , movable electric apparatus in hazardous areas .Not for reeling purposes.

Other industrial applications.

Features

Excellent flexibility

Water resistant and flame retardant

Operating temperature min. ambient temp. -25℃, max. conductor temp. 90℃.

UV, sunlight, ozone, oil, resistant

Embossing marking as per order.

Specifications

Low Voltage

Cold Resistant -25℃

UV Resistance

Water Resistance

Working Temperature 90℃

Oil Resistance

Flame Retardant

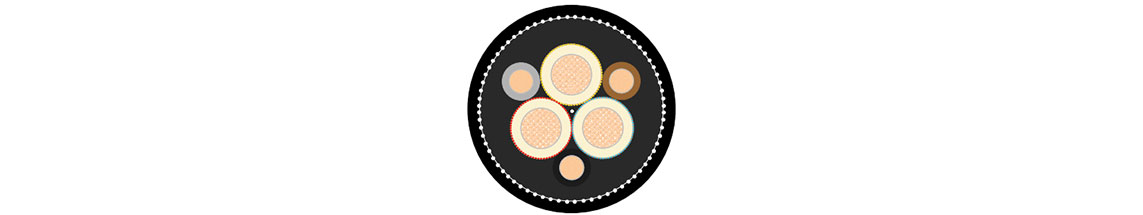

Construction

Cable type: Type 61B 0.64/1.1 kV

Conductors: Flexible class 5 comply to SANS 1411 - 1 from tinned annealed copper wires left lay with semi-conducting rubber screen .

Insulation: Ethylene propylene thermosetting compound type RD 3 comply to SANS 1411-3 and a strippable semi-conducting core screen (triple extruded)

Core of cable: Three tinned copper braided screened power cores and three unscreened pilot cores one in each interstice laid up in the right hand lay around semi-conductive rubber filler.

Inner sheath: Poly-chloroprene thermosetting compound type RS 6 comply to SANS 1411-3 .

Re-enforcement: An open nylon braid . Minimum 16 of nylon strings .

Outer sheath: Poly-chloroprene thermosetting compound type RS 6 comply to SANS 1411-3 .

Colour of sheath: Black .

Tests: SANS 1520-1.

Physical Properties | ||||||

Power Cores | ||||||

Conductor sizes (mm2) | 35 | 50 | 70 | 95 | 120 | 150 |

Maximum wire diameter ( mm) | 0.41 | 0.41 | 0.51 | 0.51 | 0.51 | 0.51 |

Approx. conductor diameter ( mm) | 8.5 | 10.3 | 11.9 | 13.5 | 15.5 | 17.3 |

Maximum screen wire diameter (mm) | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 |

Braided screen filling factor (%) | 80 | 80 | 80 | 80 | 80 | 80 |

Approx. summarized screen cross-section for power cores (weighing method) (mm2) | 27 | 32 | 37 | 43 | 47 | 52 |

Pilot Cores | ||||||

Conductor sizes ( mm2) | 6 | 6 | 16 | 16 | 16 | 16 |

Maximum wire diameter ( mm) | 0.31 | 0.31 | 0.41 | 0.41 | 0.41 | 0.41 |

Approx. conductor diameter ( mm) | 3.2 | 3.2 | 5.2 | 5.2 | 5.2 | 5.2 |

Lay Ratio (maximum) (x PCD) | 12 | 12 | 12 | 12 | 12 | 12 |

Cable Diameter | ||||||

Approx. (mm) | 41 | 42.5 | 48 | 52.3 | 58 | 63.5 |

Cable mass (approx.) (kg/m) | 3.1 | 3.6 | 4.8 | 5.7 | 7.1 | 8.5 |

Minimum bending radius (mm) | 300 | 340 | 390 | 430 | 460 | 500 |

Maximum recommended tension (kN) | 1.6 | 2.3 | 3.2 | 4.3 | 5.4 | 6.8 |

Electrical Properties | ||||||

Power cores | ||||||

Maximum cond. DC resistance @ 200C (Ω/km) | 0.576 | 0.401 | 0.283 | 0.214 | 0.167 | 0.135 |

Maximum cond. DC resistance @ 900C (Ω/km) | 0.734 | 0.511 | 0.360 | 0.273 | 0.213 | 0.171 |

Reactance (Ω/km) | 0.090 | 0.090 | 0.088 | 0.086 | 0.086 | 0.085 |

Impedance (Z) @ 900C (Ω/km) | 0.740 | 0.519 | 0.371 | 0.287 | 0.230 | 0.191 |

Sustained current rating @ 300C ambient | ||||||

Laid out straight (A) | 160 | 200 | 245 | 295 | 345 | 390 |

Short circuit rating : | ||||||

Symmetrical fault current (kA for 1 sec) | 4.3 | 6.1 | 8.5 | 11.6 | 14.6 | 18.3 |

Earth fault current (screens) (kA for 1 sec) | 2.1 | 3.1 | 3.5 | 4.1 | 4.1 | 4.1 |

Benefits

Flexibility: Easily maneuvers in confined underground spaces, reducing installation time and labor costs.

Safety Features: Water-resistant and flame-retardant, compliant with safety protocols in flood-prone or fire-risk areas, critical given South Africa's high mining accident rates.

EMI Protection: Copper shielding ensures uninterrupted power to critical equipment in high-interference environments.

Durability: High tensile strength (up to 6.8kN for 150mm²) withstands dragging and pulling, extending service life and reducing downtime amid rising input costs (2025 mining report).

Environmental Resistance: UV, oil, and ozone resistance protect against surface degradation in open-pit mines and atmospheric wear.

Cost-Efficiency: Fewer replacements due to durability, supporting cost savings.

ESG Compliance: Thermosetting compounds minimize toxic emissions during fires, aligning with ESG trends (African Mining Trends 2025).

Applications and Usage Scenarios

Primary Uses: Low-voltage setups for conveyor systems, crushers, pumps, drilling, and material handling.

Regional Applications:

South Africa: Ideal for platinum and gold mines with deep shafts requiring reliable trailing cables.

Zambia: Copper operations benefit from EMI shielding in high-interference zones.

Ghana: Weather resistance suits remote gold fields.

Botswana: Used in diamond mines for machinery in arid conditions.

DRC: Flexibility supports cobalt extraction in rugged terrain.

Other Uses: Suitable for static or semi-mobile setups in hazardous areas, quarries, and construction, but not for reeling applications.

Installation and Maintenance Recommendations

Installation:

Adhere to minimum bending radii (e.g., 300mm for 35mm²) to prevent stress fractures.

Use trained personnel for terminations, handling strippable screens carefully.

Secure cables with clamps and route away from sharp edges to avoid abrasion.

Maintenance:

Conduct regular visual inspections for cuts or swelling.

Perform electrical testing for insulation integrity.

Clean cables to remove dust or chemicals, checking for moisture ingress in humid mines.

Store in dry, shaded areas to preserve UV resistance.

Follow SANS guidelines with biennial tests in high-risk environments to extend lifespan and reduce costs.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430