Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type G Four-Conductor Round Portable Power Cable 2kV

Type G Four-Conductor Round Portable Power Cable 2 KV: Used in Continuous Miners, Conveyors, Pumps, Drills, and Loading Machines

Type G Four-Conductor Portable Power Cable 2kV ICEA S-75-381

Applications | These cables are designed for use with mobile mining equipment, such as continuous miners, cutting or loading machines,conveyors, drills or pumps. |

Standards | ICEA S-75-381/NEMA WC 58 |

Construction  | |

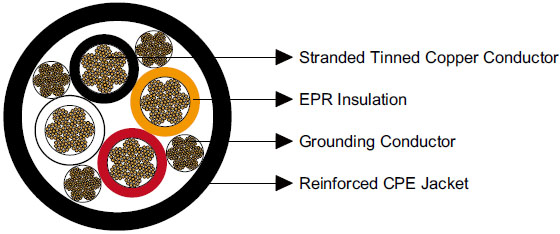

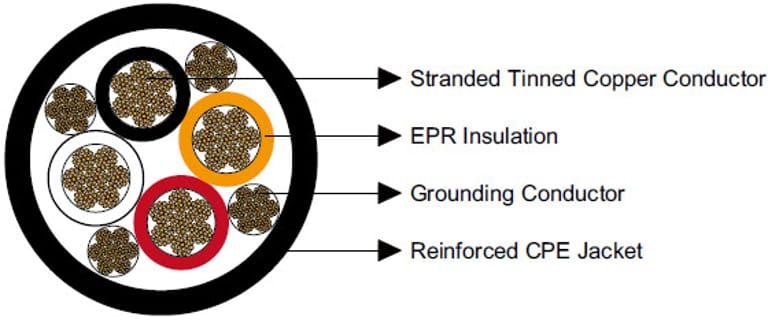

Conductors | Stranded annealed tinned copper conductor. |

Insulation | Ethylene Propylene Rubber (EPR). |

Grounding Conductor | Tinned copper conductor with a green outer covering. |

Jacket | Reinforced heavy-duty/extra-heavy-duty Chlorinated Polyethylene (CPE), black. (Cables having a nominal outside diameter of more than 2.0 inches require extra-heavy-duty jackets.) |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

4×6 | 259 | 12 | 0.06 | 1.5 | 0.140 | 3.6 | 1.10 | 27.9 | 910 | 1354 | 72 |

4×4 | 412 | 10 | 0.06 | 1.5 | 0.155 | 3.9 | 1.27 | 32.3 | 1378 | 2050 | 93 |

4×2 | 259 | 9 | 0.06 | 1.5 | 0.170 | 4.3 | 1.48 | 37.6 | 1914 | 2848 | 122 |

4×1 | 331 | 8 | 0.08 | 2.0 | 0.190 | 4.8 | 1.68 | 42.7 | 2311 | 3438 | 143 |

4×1/0 | 414 | 7 | 0.08 | 2.0 | 0.190 | 4.8 | 1.79 | 45.5 | 2810 | 4181 | 165 |

4×2/0 | 522 | 6 | 0.08 | 2.0 | 0.190 | 4.8 | 1.93 | 49.0 | 3253 | 4840 | 192 |

4×3/0 | 658 | 5 | 0.08 | 2.0 | 0.205 | 5.2 | 2.07 | 52.6 | 4099 | 6099 | 221 |

4×4/0 | 829 | 4 | 0.08 | 2.0 | 0.220 | 5.6 | 2.26 | 57.4 | 4925 | 7327 | 255 |

4×250 | 973 | 3 | 0.095 | 2.4 | 0.235 | 6.0 | 2.66 | 67.6 | 6060 | 9016 | 280 |

4×350 | 1361 | 1 | 0.095 | 2.4 | 0.250 | 6.4 | 2.98 | 75.7 | 8126 | 12090 | 335 |

4×500 | 1921 | 1/0 | 0.095 | 2.4 | 0.280 | 7.1 | 3.40 | 86.4 | 10758 | 16006 | 395 |

The rapid expansion of mining and heavy industries in South Africa has placed increasing demands on electrical infrastructure. From deep-level gold mines in Gauteng to open-cast coal operations in Mpumalanga, reliable power distribution is essential for safe and efficient operations. One cable type that stands out for such demanding conditions is the Type G Four-Conductor Round Portable Power Cable, rated at 2kV.

Designed specifically for portable and mobile equipment, Type G cables provide robust electrical performance under extreme mechanical stress. They are commonly used in continuous miners, conveyors, pumps, drills, and loading machines, which form the backbone of mining and quarrying operations. With rugged construction, high flexibility, and compliance with ICEA, NEMA, ASTM, and CSA standards, these cables are essential for safe energy distribution in harsh environments.

What is a Type G Four-Conductor Portable Power Cable?

Type G portable cables are multi-conductor flexible power cables designed for temporary or mobile applications where frequent movement, abrasion, and exposure to mechanical stress are expected.

Voltage rating: 2kV (2000 volts)

Conductor configuration: Four insulated power conductors plus grounding conductors

Applications: Mining machinery, industrial equipment, construction tools, and portable power distribution systems

In South Africa’s mining sector, these cables are crucial for mobile machinery that requires continuous power while moving, such as shuttle cars in coal mines or drilling rigs in platinum mines.

Benefits of Type G Portable Power Cables

High Flexibility – Designed for frequent bending, rolling, and movement without conductor fatigue.

Abrasion Resistance – Rugged CPE jackets protect against sharp rocks and heavy machinery.

Moisture and Chemical Resistance – Essential in damp underground mines where exposure to water and oil is common.

Thermal Stability – Operates reliably at up to 90°C, ensuring durability in hot South African mine shafts.

Safety – Built-in grounding conductors reduce the risk of electrical accidents.

Versatility – Can power a wide variety of mining equipment, from drills to conveyor belts.

Use Cases in Mining and Heavy Industry

Case Study 1 – Platinum Mining in Rustenburg

A platinum mine in Rustenburg deployed Type G 2kV cables for powering drilling rigs. The flexible EPR insulation allowed continuous movement, while the rugged CPE jacket prevented failures caused by contact with sharp rock faces. Downtime due to cable failure dropped by 30%, improving production efficiency.

Case Study 2 – Coal Mining in Mpumalanga

In coal mines, conveyors must operate continuously. Using Type G 2kV cables with extra-heavy-duty jackets helped reduce frequent replacements caused by abrasive coal dust. Operators reported a 40% increase in cable lifespan.

Case Study 3 – Industrial Ports in Durban

Beyond mining, Type G cables are also used in port cranes and heavy industrial machinery. Their oil- and chemical-resistant jackets withstand exposure to marine environments, reducing maintenance costs in Durban’s busy shipping terminals.

Frequently Asked Questions (FAQ)

Q1: What is the maximum operating voltage of a Type G portable power cable?

A: Type G cables are rated for 2000 volts (2kV).

Q2: Can Type G cables be used underground in wet mines?

A: Yes, their tinned copper conductors and CPE jackets make them highly resistant to moisture and chemicals.

Q3: How often should Type G cables be inspected in mining operations?

A: Best practice is monthly visual inspections and annual electrical testing, though high-stress operations may require more frequent checks.

Q4: What is the difference between Type G and Type W cables?

A: While both are portable power cables, Type W cables are heavier-duty and often used for power distribution, whereas Type G is optimized for mobile equipment with four conductors and integrated grounding.

Q5: Are Type G cables approved for use in South Africa?

A: Yes, provided they meet international standards (ICEA/NEMA/ASTM/CSA) and align with South African Bureau of Standards (SABS) safety requirements for mining operations.

The Type G Four-Conductor Round Portable Power Cable 2kV is a vital component of South Africa’s mining and heavy industry sectors. Its robust design, flexibility, and resistance to harsh environments make it indispensable for powering mobile mining equipment and industrial machinery.

As South Africa continues modernising its mining operations and moving toward electrification and safety-focused innovation, reliable portable power cables will play a critical role. By following best practices for installation, inspection, and maintenance, operators can maximise the lifespan of these cables while ensuring the safety and efficiency of their operations.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430