Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type G-GC Three-Conductor Flat Portable Power Cable 2kV ICEA S-75-381

Understanding Type G-GC Three-Conductor Flat Portable Power Cable 2kV ICEA S-75-381 for Mining and Heavy Industry in South Africa

Type G-GC Three-Conductor Flat Portable Power Cable 2kV ICEA S-75-381

Applications | These flat parallel cables are designed for use on ACmining equipment, such as A.C. shuttle cars, drills, cutting and loading machines. |

Standards | ICEA S-75-381/NEMA WC 58 |

Construction  | |

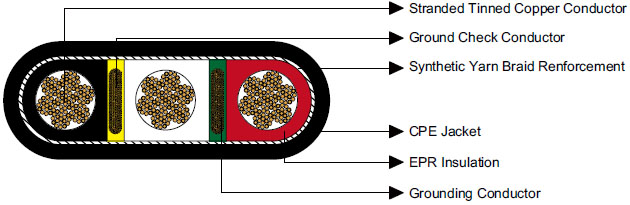

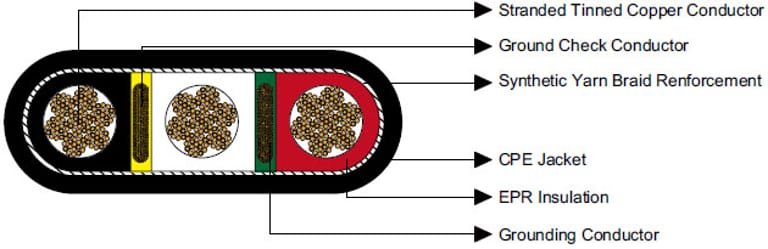

Conductors | Stranded annealed tinned copper conductor. |

Insulation | Ethylene Propylene Rubber (EPR). |

Ground Check Conductor | Tinned copper conductor with a yellow insulation. |

Grounding Conductor | Tinned copper conductor with an optional green outer covering. |

Reinforcement | Synthetic yarn. |

Jacket | Heavy-duty/extra-heavy-duty Chlorinated Polyethylene (CPE), black. (Cables having a nominal outside diameter of more than 2.0 inches require extra-heavy-duty jackets.) |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Ground Check Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter Height×Width | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×6 | 133 | 8 | 8 | 0.06 | 1.5 | 0.095 | 2.4 | 0.66×1.67 | 16.8×42.4 | 900 | 1340 | 79 |

3×4 | 259 | 7 | 8 | 0.06 | 1.5 | 0.095 | 2.4 | 0.72×1.87 | 18.3×47.5 | 1175 | 1750 | 104 |

3×3 | 259 | 6 | 6 | 0.06 | 1.5 | 0.110 | 2.8 | 0.78×2.08 | 19.8×52.8 | 1395 | 2080 | 120 |

3×2 | 259 | 5 | 6 | 0.06 | 1.5 | 0.110 | 2.8 | 0.85×2.23 | 21.6×56.6 | 1625 | 2415 | 138 |

3×1 | 259 | 4 | 6 | 0.08 | 2.0 | 0.125 | 3.2 | 0.96×2.50 | 24.4×63.5 | 2090 | 3110 | 161 |

3×1/0 | 259 | 3 | 5 | 0.08 | 2.0 | 0.140 | 3.6 | 1.01×2.67 | 25.6×67.8 | 2470 | 3675 | 186 |

3×2/0 | 329 | 2 | 5 | 0.08 | 2.0 | 0.140 | 3.6 | 1.09×2.86 | 27.7×68.1 | 2940 | 4375 | 215 |

3×3/0 | 413 | 1 | 5 | 0.08 | 2.0 | 0.155 | 3.9 | 1.18×3.12 | 30.0×79.2 | 3515 | 5230 | 249 |

3×4/0 | 532 | 1/0 | 5 | 0.08 | 2.0 | 0.155 | 3.9 | 1.24×3.30 | 31.5×83.8 | 4245 | 6315 | 287 |

The mining and heavy industry sectors in South Africa depend heavily on reliable power distribution systems that can endure extreme operating environments. In underground mines, open-cast operations, and large-scale industrial facilities, cables face constant exposure to mechanical stress, abrasion, moisture, and chemical contaminants. Among the specialized cables developed to meet these challenges is the Type G-GC three-conductor flat portable power cable, 2kV, built according to ICEA S-75-381 standards.

What Is a Type G-GC Cable?

Type G-GC cables are a class of portable power cables designed to deliver electricity in environments where mobility, flexibility, and durability are essential. The “G” designation indicates grounding conductors, while the “GC” specifies an additional ground check conductor, used to continuously monitor the integrity of the ground path—an essential safety feature in mining applications.

These cables are flat parallel constructions that enable efficient routing in confined areas, reducing space requirements and improving handling in tunnels, shafts, and along machinery.

Applicable Standards

Type G-GC portable power cables are manufactured in accordance with international standards to ensure consistency and performance:

ICEA S-75-381 / NEMA WC 58 – Governs portable and mining cables.

ASTM B 172 and ASTM B 33 – Standards for copper conductor materials.

CAN/CSA C22.2 No. 96 – Canadian safety compliance for mining cables.

For South Africa, while ICEA standards apply to imported cables, they are often benchmarked against SANS 1520-1 requirements and must be certified under the National Regulator for Compulsory Specifications (NRCS) before deployment in mines.

Benefits of Type G-GC Portable Power Cable

Enhanced Safety

Integrated grounding and ground-check conductors ensure safe fault detection.

Prevents shock hazards in underground and surface mining.

Mechanical Durability

Reinforced jackets resist abrasion, tearing, and impact.

Suitable for high-tension environments where cables are dragged or reeled.

Flexibility and Handling

Flat profile allows for easy routing in confined spaces.

Stranded copper construction provides excellent bendability.

Thermal and Chemical Resistance

EPR insulation and CPE jackets withstand oils, moisture, and chemicals.

Performs reliably in hot, humid, or corrosive environments.

Long Service Life

Heavy-duty jacket materials reduce the need for frequent replacements, lowering operational costs.

Applications in Mining and Heavy Industry

Type G-GC portable power cables are particularly suited to:

Underground mining machinery: Shuttle cars, continuous miners, drills, and cutting equipment.

Open-pit mining operations: Draglines, shovels, and auxiliary power systems.

Construction and tunneling projects: Heavy-duty portable power supply.

Industrial plants: Power distribution for moving machinery and cranes.

Case Studies: South Africa

1. Gold Mining in Gauteng

In Johannesburg’s deep-level gold mines, operators rely on Type G-GC cables to power shuttle cars and drills in narrow shafts. The flat construction enables efficient cable management along confined passages while ensuring electrical safety through ground-check monitoring.

2. Platinum Mining in Rustenburg

With the rising demand for safe and NRCS-compliant cables, platinum mining companies in North West Province are increasingly turning to G-GC cables for reliability in wet and chemically aggressive environments. The CPE jacket provides the necessary resistance to chemical corrosion from mining by-products.

3. Coal Mining in Mpumalanga

Surface coal operations demand cables that can withstand reeling and dragging. The reinforced two-layer G-GC design has proven successful in reducing mechanical wear, cutting downtime caused by frequent cable replacements.

Frequently Asked Questions (FAQ)

Q1. Why is the ground check conductor important?

It continuously monitors the grounding system, preventing electrical shock hazards in mining environments.

Q2. Can Type G-GC cables be used outdoors?

Yes. With CPE or PCP jackets, they are suitable for outdoor use, resistant to sunlight, moisture, and abrasion.

Q3. How do Type G-GC cables compare with Type W or Type G cables?

Type G-GC: Includes both grounding and ground-check conductors, best for mining.

Type G: Contains grounding but no ground-check conductor.

Type W: Designed for extra-hard usage, often in industrial or construction applications.

Q4. Are these cables compatible with South African standards?

Yes, but they must undergo NRCS approval for use in South African mines, aligning ICEA specifications with SANS 1520-1.

Q5. What is the service life of a G-GC cable?

Depending on operating conditions, 5–10 years, with proper installation and maintenance extending lifespan.

The Type G-GC three-conductor flat portable power cable (2kV, ICEA S-75-381) is a cornerstone of modern mining and heavy industry, offering safety, flexibility, and durability under extreme operating conditions. For South African mines—where harsh geology and regulatory requirements create unique challenges—G-GC cables provide dependable performance, meeting international and local compliance standards.

By understanding the technical specifications, benefits, applications, and maintenance practices, mining operators and engineers can make informed decisions that enhance safety, efficiency, and operational reliability. With growing emphasis on sustainability and digital monitoring, these cables will continue to play a vital role in South Africa’s mining future.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430