Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type G-GC Three-Conductor Round Portable Power Cable 2kV ICEA S-75-381

Type G-GC Three-Conductor Round Portable Power Cable (2kV): Designed Specifically for Demanding Industrial Applications

Type G-GC Three-Conductor Portable Power Cable 2kV ICEA S-75-381

Applications | These cables are suitable for use with mobile mining equipment such as continuous miners, drills, cutters, loading machines, AC shuttle cars and pumps. Type G-GC is for applications where grounding conductors and a ground check conductor are required. |

Standards | ICEA S-75-381/NEMA WC 58 |

Construction  | |

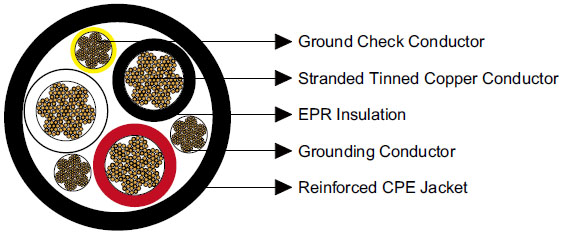

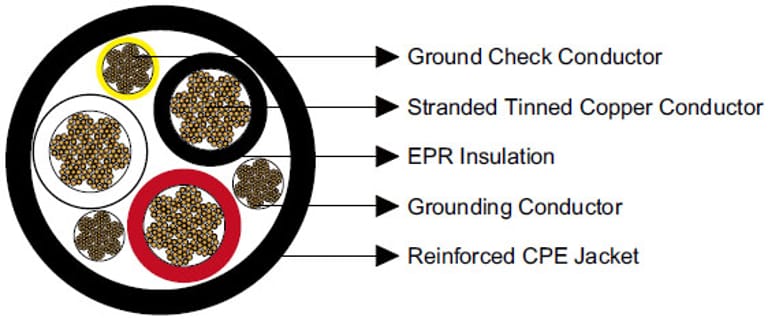

Conductors | Stranded annealed tinned copper conductor. |

Insulation | Ethylene Propylene Rubber (EPR). |

Ground Check Conductor | Tinned copper conductor with a yellow insulation. |

Grounding Conductor | Tinned copper conductor with an optional green outer covering. |

Jacket | Reinforced heavy-duty/extra-heavy-duty Chlorinated Polyethylene (CPE), black. (Cables having a nominal outside diameter of more than 2.0 inches require extra-heavy-duty jackets.) |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Ground Check Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×8 | 133 | 10 | 10 | 0.06 | 1.5 | 0.125 | 3.2 | 0.97 | 24.6 | 600 | 893 | 59 |

3×6 | 133 | 10 | 10 | 0.06 | 1.5 | 0.140 | 3.6 | 1.05 | 26.7 | 735 | 1094 | 79 |

3×4 | 259 | 8 | 10 | 0.06 | 1.5 | 0.155 | 3.9 | 1.19 | 30.2 | 1065 | 1585 | 104 |

3×3 | 259 | 8 | 10 | 0.06 | 1.5 | 0.155 | 3.9 | 1.25 | 31.8 | 1245 | 1853 | 120 |

3×2 | 259 | 7 | 10 | 0.06 | 1.5 | 0.155 | 3.9 | 1.34 | 34.0 | 1480 | 2202 | 138 |

3×1 | 259 | 6 | 8 | 0.08 | 2.0 | 0.170 | 4.3 | 1.51 | 38.4 | 1885 | 2805 | 161 |

3×1/0 | 266 | 5 | 8 | 0.08 | 2.0 | 0.170 | 4.3 | 1.65 | 41.9 | 2290 | 3408 | 186 |

3×2/0 | 329 | 4 | 8 | 0.08 | 2.0 | 0.190 | 4.8 | 1.75 | 44.5 | 2710 | 4033 | 215 |

3×3/0 | 418 | 2 | 8 | 0.08 | 2.0 | 0.190 | 4.8 | 1.89 | 48.0 | 3270 | 4866 | 249 |

3×4/0 | 532 | 2 | 8 | 0.08 | 2.0 | 0.205 | 5.2 | 2.04 | 51.8 | 3975 | 5915 | 287 |

3×250 | 627 | 2 | 6 | 0.095 | 2.4 | 0.220 | 5.6 | 2.39 | 60.7 | 4950 | 7366 | 320 |

3×350 | 888 | 1/0 | 6 | 0.095 | 2.4 | 0.235 | 6.0 | 2.68 | 68.1 | 6625 | 9859 | 394 |

3×500 | 1221 | 2/0 | 6 | 0.095 | 2.4 | 0.250 | 6.4 | 3.03 | 77.0 | 8890 | 13230 | 487 |

In the world of mining, tunneling, and heavy industry, safe and reliable power distribution is the backbone of productivity. With equipment often subjected to extreme mechanical stress, harsh weather, and abrasive environments, the choice of cable is critical. Among the most trusted solutions is the Type G-GC three-conductor round portable power cable (2kV), designed specifically for demanding industrial applications.

Understanding Type G-GC Cable

What Is Type G-GC Cable?

Type G-GC (Grounding with Ground Check) cable is a flexible, portable power cable designed for use in harsh environments where equipment mobility and grounding integrity are essential.

It features:

Three power conductors for current transmission.

Multiple grounding conductors for safety.

One ground check conductor to monitor circuit integrity.

Key Standards

Type G-GC cables conform to multiple international standards, ensuring performance and safety:

ICEA S-75-381 / NEMA WC 58 – for portable and power cables.

ASTM B 172 & ASTM B 33 – governing conductor materials.

CAN/CSA C22.2 No. 96 – Canadian standard for flexible cords and cables.

This compliance makes Type G-GC cable a trusted solution not just in the U.S. and Canada, but also in global markets such as South Africa, where mining cable safety is heavily regulated.

Benefits of Type G-GC Cable

Safety Assurance – Multiple grounding conductors and a dedicated ground check conductor reduce risks of electric shock and ensure continuous monitoring.

Mechanical Strength – Reinforced jackets withstand constant flexing, dragging, and abrasion.

Thermal and Electrical Stability – EPR insulation maintains integrity at elevated temperatures.

Flexibility – Stranded tinned copper ensures easy handling and installation in confined spaces.

Chemical Resistance – CPE jackets resist oil, ozone, sunlight, and many industrial chemicals.

Longevity – Built for rugged environments, reducing replacement cycles and downtime.

Usage Scenarios

Mining Equipment

Continuous miners

Drills and cutters

Loading machines

AC shuttle cars

Pumps

Heavy Industry Applications

Portable power distribution in steel mills and shipyards.

Power supply for tunneling machines.

Electrical connections for construction cranes and portable substations.

Case Studies in South Africa

Case Study 1: Platinum Mining in Rustenburg

A platinum mine in Rustenburg, one of South Africa’s largest mining hubs, reported frequent downtime due to damaged trailing cables. Switching to Type G-GC with extra-heavy-duty jackets reduced replacement frequency by 40%, saving both cost and production time.

Case Study 2: Gold Mining in Witwatersrand

In the Witwatersrand Basin, gold mining operations demanded cables with superior grounding safety due to high water ingress in shafts. Type G-GC’s dedicated ground check conductor allowed real-time fault detection, significantly improving mine safety compliance with local standards.

Case Study 3: Port Cranes in Durban

At the Port of Durban, container handling cranes required flexible yet durable cables. Type G-GC cables, with their strong abrasion-resistant CPE jackets, proved effective under constant mechanical stress and salty marine environments.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between Type G and Type G-GC cable?

Type G has grounding conductors only, while Type G-GC includes both grounding conductors and a ground check conductor, making it safer for mining use.

Q2: Can Type G-GC cable be used outdoors?

Yes. Its CPE jacket provides excellent resistance to UV, ozone, moisture, and oils, making it suitable for outdoor use.

Q3: How often should these cables be inspected in mining applications?

A daily visual inspection is recommended in mining, with detailed electrical testing performed weekly or monthly depending on use.

Q4: Are Type G-GC cables suitable for renewable energy applications?

Yes, they can be adapted for portable power distribution in renewable energy projects such as mobile solar or wind installations, though they are primarily designed for mining.

Type G-GC portable power cables represent a critical link in mining and heavy industry operations, providing safe, reliable, and durable power connections in the most challenging environments.

With their robust construction, grounding safety features, and compliance with international standards, they are especially relevant in South Africa’s mining sector, where operational safety and efficiency are top priorities.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430