Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type G Three-Conductor Portable Power Cable 2kV ICEA S-75-381

Type G Three-Conductor Portable Power Cables (2kV) Enhance South Africa’s Mining and Heavy Industry with Durability, Safety, and Efficiency

Type G Three-Conductor Portable Power Cable 2kV ICEA S-75-381

Applications | These cables are designed for use with mobile mining equipment, such as continuous miners, cutting or loading machines, conveyors, drills or pumps. |

Standards | ICEA S-75-381/NEMA WC 58 |

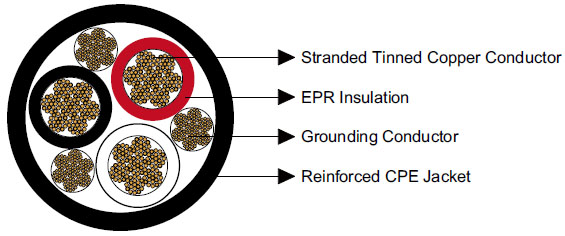

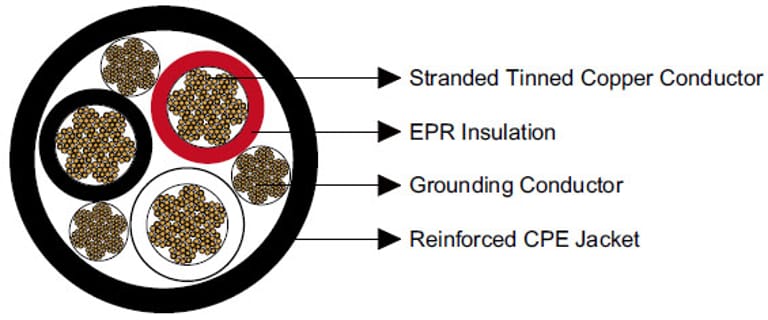

Construction  | |

Conductors | Stranded annealed tinned copper conductor. |

Insulation | Ethylene Propylene Rubber (EPR). |

Grounding Conductor | Tinned copper conductor with a green outer covering. |

Jacket | Reinforced heavy-duty/extra-heavy-duty Chlorinated Polyethylene (CPE), black. (Cables having a nominal outside diameter of more than 2.0 inches require extra-heavy-duty jackets.) |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×8 | 133 | 10 | 0.06 | 1.5 | 0.125 | 3.2 | 0.91 | 23.1 | 590 | 878 | 59 |

3×6 | 168 | 10 | 0.06 | 1.5 | 0.140 | 3.6 | 1.01 | 25.7 | 760 | 1131 | 79 |

3×4 | 259 | 8 | 0.06 | 1.5 | 0.155 | 3.9 | 1.17 | 29.7 | 1070 | 1592 | 104 |

3×3 | 329 | 8 | 0.06 | 1.5 | 0.155 | 3.9 | 1.24 | 31.5 | 1280 | 1904 | 120 |

3×2 | 259 | 8 | 0.06 | 1.5 | 0.155 | 3.9 | 1.34 | 34.0 | 1530 | 2276 | 138 |

3×1 | 329 | 7 | 0.08 | 2.0 | 0.170 | 4.3 | 1.51 | 38.4 | 1890 | 2812 | 161 |

3×1/0 | 259 | 6 | 0.08 | 2.0 | 0.170 | 4.3 | 1.65 | 41.9 | 2320 | 3452 | 186 |

3×2/0 | 329 | 5 | 0.08 | 2.0 | 0.190 | 4.8 | 1.75 | 44.5 | 2700 | 4017 | 215 |

3×3/0 | 413 | 4 | 0.08 | 2.0 | 0.190 | 4.8 | 1.89 | 48.0 | 3270 | 4865 | 249 |

3×4/0 | 532 | 3 | 0.08 | 2.0 | 0.205 | 5.2 | 2.04 | 51.8 | 3970 | 5907 | 287 |

3×250 | 608 | 2 | 0.095 | 2.4 | 0.220 | 5.6 | 2.39 | 60.7 | 5080 | 7558 | 320 |

3×300 | 741 | 1 | 0.095 | 2.4 | 0.235 | 6.0 | 2.56 | 65.0 | 6080 | 9046 | 357 |

3×350 | 855 | 1 | 0.095 | 2.4 | 0.235 | 6.0 | 2.68 | 68.1 | 7140 | 10623 | 394 |

3×400 | 988 | 1/0 | 0.095 | 2.4 | 0.250 | 6.4 | 2.82 | 71.6 | 7780 | 11575 | 430 |

3×500 | 1221 | 2/0 | 0.095 | 2.4 | 0.250 | 6.4 | 3.03 | 77.0 | 9065 | 13487 | 487 |

Introduction

South Africa’s mining and heavy industry sectors are the backbone of its economy, extracting valuable minerals like gold, platinum, and coal. These industries rely on robust, reliable equipment to operate in harsh environments. One critical component is the Type G Three-Conductor Portable Power Cable (2kV), designed to power mobile mining equipment such as continuous miners, conveyors, drills, and pumps. This article explores the technical specifications, benefits, installation and maintenance recommendations, usage scenarios, and real-world case studies of these cables, with a focus on their role in South Africa’s mining sector. We’ll also address frequently asked questions to provide a comprehensive guide for industry professionals and enthusiasts.

What Are Type G Three-Conductor Portable Power Cables?

Type G Three-Conductor Portable Power Cables are heavy-duty, flexible cables engineered for high-voltage applications up to 2,000 volts (2kV). They are specifically designed for mobile equipment in demanding environments like mining, where durability, safety, and reliability are paramount. These cables comply with industry standards such as ICEA S-75-381/NEMA WC 58, ASTM B 172, ASTM B 33, and CAN/CSA C22.2 No. 96, ensuring consistent performance under extreme conditions.

Benefits of Type G Portable Power Cables

Type G cables offer several advantages that make them ideal for South Africa’s mining and heavy industry sectors:

Durability: The CPE jacket and EPR insulation provide resistance to abrasion, chemicals, and extreme temperatures, ensuring longevity in harsh mining environments.

Flexibility: Stranded copper conductors and a minimum bending radius of 6×OD allow the cables to adapt to the dynamic movements of mobile equipment.

Safety: The tinned copper grounding conductor ensures reliable grounding, reducing the risk of electrical faults and enhancing worker safety.

Versatility: Suitable for a wide range of equipment, from continuous miners to pumps, making them a versatile choice for mining operations.

Compliance: Adherence to international standards ensures reliability and compatibility with global equipment.

Usage Scenarios in South Africa’s Mining Industry

Type G Three-Conductor Portable Power Cables are integral to South Africa’s mining operations, where they power critical equipment in gold, platinum, and coal mines. Below are two key usage scenarios:

1. Continuous Miners in Platinum Mines

South Africa is the world’s largest producer of platinum, with mines like those in the Bushveld Complex relying on continuous miners. These machines require flexible, high-capacity power cables to operate in confined underground spaces. A 3×2/0 AWG Type G cable, with an ampacity of 215A and a nominal diameter of 1.75 inches, is ideal for powering continuous miners, offering the flexibility to navigate tight bends and the durability to withstand abrasive rock surfaces.

2. Conveyor Systems in Coal Mines

Coal mines, such as those in Mpumalanga, use conveyor systems to transport coal to the surface. These systems demand reliable power delivery over long distances. A 3×350 kcmil Type G cable, with an ampacity of 394A and a robust CPE jacket, ensures uninterrupted operation, even in dusty and humid conditions. The cable’s grounding conductor enhances safety by mitigating electrical risks in potentially explosive environments.

Type G Three-Conductor Portable Power Cables (2kV) are a cornerstone of South Africa’s mining and heavy industry sectors, offering unmatched durability, flexibility, and safety. Their technical specifications, including stranded copper conductors, EPR insulation, and robust CPE jackets, make them ideal for powering mobile equipment in harsh environments. By following proper installation and maintenance practices, mines can maximize efficiency and safety while addressing current industry challenges. Real-world case studies demonstrate their impact on reducing downtime and costs, making them a vital investment for South Africa’s mining future. Whether in gold, platinum, or coal mines, Type G cables are powering the industry forward.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430