Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type G Two-Conductor Flat Portable Power Cable 2kV

Type G Two-Conductor Flat Portable Power Cables for Heavy-Duty Applications

Type G Two-Conductor Flat Portable Power Cable 2kV

Applications | These flat parallel cables are designed for use on D.C. off-track mining equipment, such as D.C. shuttle cars, drills,cutting and loading machines. |

Standards | ICEA S-75-381/NEMA WC 58 |

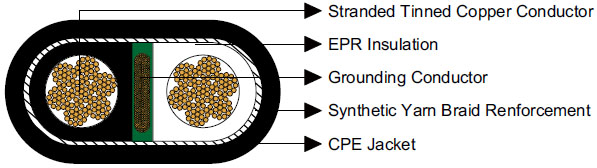

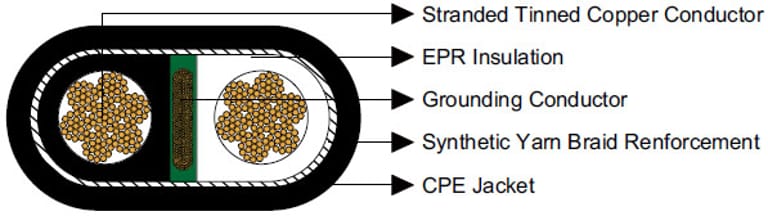

Construction  | |

Conductors | Stranded annealed tinned copper conductor. |

Insulation | Ethylene Propylene Rubber (EPR). |

Grounding Conductor | Tinned copper conductor with a green outer covering. |

Reinforcement | Synthetic yarn. |

Jacket | Heavy-duty/extra-heavy-duty Chlorinated Polyethylene (CPE), black. (Cables having a nominal outside diameter of more than 2.0 inches require extra-heavy-duty jackets.) |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter Height×Width | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

2×6 | 133 | 8 | 0.06 | 1.5 | 0.080 | 2.0 | 0.56×1.02 | 14.2×25.9 | 500 | 744 | 95 |

2×4 | 259 | 7 | 0.06 | 1.5 | 0.095 | 2.4 | 0.61×1.15 | 15.5×29.2 | 635 | 945 | 127 |

2×3 | 259 | 6 | 0.06 | 1.5 | 0.095 | 2.4 | 0.68×1.26 | 17.3×32.0 | 785 | 1170 | 145 |

2×2 | 259 | 5 | 0.06 | 1.5 | 0.095 | 2.4 | 0.73×1.35 | 18.5×34.3 | 935 | 1390 | 167 |

2×1 | 259 | 4 | 0.08 | 2.0 | 0.110 | 2.8 | 0.81×1.55 | 20.6×39.4 | 1185 | 1760 | 191 |

2×1/0 | 259 | 3 | 0.08 | 2.0 | 0.125 | 3.2 | 0.93×1.67 | 23.6×42.4 | 1470 | 2190 | 217 |

2×2/0 | 329 | 2 | 0.08 | 2.0 | 0.125 | 3.2 | 0.99×1.85 | 25.1×47.0 | 1790 | 2660 | 250 |

2×3/0 | 413 | 1 | 0.08 | 2.0 | 0.140 | 3.6 | 1.03×2.00 | 26.2×50.8 | 2145 | 3190 | 286 |

2×4/0 | 532 | 1/0 | 0.08 | 2.0 | 0.140 | 3.6 | 1.10×2.10 | 27.9×53.3 | 2545 | 3790 | 328 |

Introduction to Type G Flat Portable Power Cables

In the heart of South Africa’s mining and heavy industry sectors, where rugged environments demand reliable power solutions, Type G flat portable power cables are transforming operations. These cables, designed for direct current (D.C.) off-track mining equipment like shuttle cars, drills, and loading machines, offer unmatched durability and flexibility. This article explores the technical specifications, benefits, installation and maintenance practices, and real-world applications of Type G cables, with a focus on their impact in South Africa’s mining industry.

What Are Type G Flat Portable Power Cables?

Type G flat portable power cables are two-conductor cables engineered for high-performance power delivery in harsh industrial settings. Their flat, parallel design optimizes space and flexibility, making them ideal for mobile mining equipment. Compliant with standards like ICEA S-75-381/NEMA WC 58, ASTM B 172, ASTM B 33, and CAN/CSA C22.2 No. 96, these cables are built to withstand extreme conditions, including high temperatures and mechanical stress.

Benefits of Type G Flat Portable Power Cables

Durability: The CPE jacket and synthetic yarn reinforcement protect against abrasion, chemicals, and mechanical stress, extending cable lifespan in harsh mining conditions.

Flexibility: The flat design and stranded conductors allow easy bending (minimum radius of 6×OD), ideal for mobile equipment.

High Ampacity: With capacities ranging from 95 A to 328 A, Type G cables support heavy-duty machinery.

Safety: The tinned copper grounding conductor minimizes electrical hazards.

Customizability: Options for alternative jackets and two-layer designs cater to specific operational needs.

Usage Scenarios in South African Mining

South Africa’s mining industry, a cornerstone of the economy, relies heavily on robust power solutions. Type G flat portable power cables are widely used in:

Underground Mining: In gold and platinum mines, such as those in the Witwatersrand Basin, Type G cables power D.C. shuttle cars and cutting machines, navigating tight spaces due to their flat design.

Surface Mining: In coal mines in Mpumalanga, these cables support mobile drills and loading equipment, withstanding dust and high temperatures.

Heavy Industry: Beyond mining, Type G cables are used in steel manufacturing plants in Gauteng, powering heavy machinery in harsh environments.

Case Study: Enhancing Safety and Efficiency in a South African Platinum Mine

In 2024, a major platinum mine in Rustenburg faced frequent downtime due to cable failures in their D.C. shuttle cars. The mine adopted Type G 2×2/0 AWG cables with a two-layer CPE jacket. The flat design reduced tripping hazards, and the reinforced jacket withstood abrasive rock surfaces. Post-installation, the mine reported a 30% reduction in downtime and improved worker safety due to the reliable grounding conductor. This case underscores the importance of selecting cables tailored to specific environmental challenges.

Case Study: Coal Mining in Mpumalanga

A coal mine in eMalahleni upgraded its drilling equipment with Type G 2×4/0 AWG cables to support higher ampacity needs. The cables’ flexibility and high temperature tolerance (+90°C) ensured uninterrupted operation in the region’s hot climate. The mine saw a 25% increase in drilling efficiency, highlighting the cables’ role in boosting productivity.

Type G flat portable power cables are a game-changer for South Africa’s mining and heavy industry sectors. Their robust construction, flexibility, and high performance make them indispensable for powering D.C. equipment in challenging environments. By following proper installation and maintenance practices, mines can maximize efficiency, safety, and sustainability. As South Africa’s mining industry evolves, Type G cables will continue to play a pivotal role in driving productivity and innovation.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430