Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type MP-GC Three-Conductor Mine Power Feeder Cable, CPE Jacket, 15kV to ICEA S-75-381

Type MP-GC Three-Conductor Mine Power Feeder Cable with a CPE jacket, 15kV rated to ICEA S-75-381

Type MP-GC Three-Conductor Mine Power Feeder Cable, CPE Jacket, 15kV to ICEA S-75-381

Applications | These cables are designed for connections between units of mine distribution systems, suitable forinstalled in duct, conduit or open air and for direct burial in wet and dry locations. |

Standards | ICEA S-75-381/NEMA WC 58 |

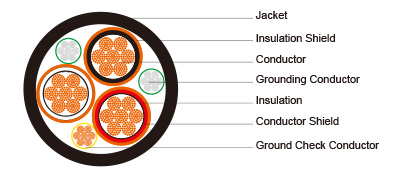

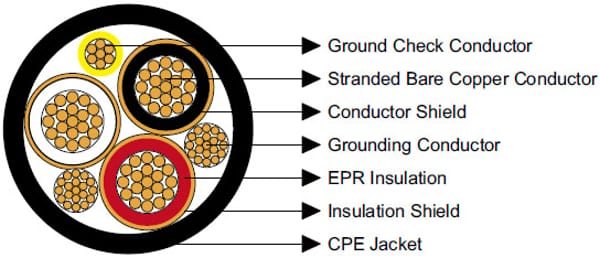

Construction  | |

Conductors | Stranded annealed bare copper conductor. |

Conductor Shield | Conducting layer. |

Insulation | Ethylene Propylene Rubber (EPR). |

Insulation Shield | Conducting layer + copper tape. |

Ground Check Conductor | Copper conductor with a yellow polypropylene insulation. |

Grounding Conductor | Tinned copper conductor. |

Jacket | Chlorinated Polyethylene(CPE), black. |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 12×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Ground Check Conductor SizeL | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | AWG/KCMI | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×2 | 7 | 6 | 8 | 0.175 | 4.4 | 0.14 | 3.6 | 1.90 | 48.3 | 2517 | 3745 | 164 |

3×1 | 19 | 5 | 8 | 0.175 | 4.4 | 0.14 | 3.6 | 1.99 | 50.6 | 3023 | 4498 | 187 |

3×1/0 | 19 | 4 | 8 | 0.175 | 4.4 | 0.14 | 3.6 | 2.07 | 52.6 | 3296 | 4904 | 215 |

3×2/0 | 19 | 3 | 8 | 0.175 | 4.4 | 0.14 | 3.6 | 2.16 | 54.9 | 3679 | 5474 | 246 |

3×3/0 | 19 | 2 | 8 | 0.175 | 4.4 | 0.14 | 3.6 | 2.27 | 57.7 | 3878 | 5771 | 283 |

3×4/0 | 19 | 1 | 8 | 0.175 | 4.4 | 0.14 | 3.6 | 2.39 | 60.7 | 5146 | 7656 | 325 |

3×250 | 37 | 1/0 | 8 | 0.175 | 4.4 | 0.14 | 3.6 | 2.48 | 63.0 | 5618 | 8359 | 359 |

3×350 | 37 | 2/0 | 8 | 0.175 | 4.4 | 0.14 | 3.6 | 2.70 | 68.6 | 7055 | 10496 | 438 |

3×500 | 37 | 4/0 | 8 | 0.175 | 4.4 | 0.17 | 4.3 | 3.08 | 78.2 | 9405 | 13993 | 536 |

Application Scenarios

The MP-GC cable is widely deployed in mine distribution systems, but its versatility extends further.

Underground Mining

Powering conveyors, ventilation systems, dewatering pumps, and drill rigs in deep gold and platinum mines of Gauteng and North West.

Surface Mining & Coal Operations

Distributing high-voltage electricity to draglines, shovels, and crushers in Mpumalanga’s coalfields.

Industrial Installations

Supplying substations, heavy-duty pumps, or milling systems in steel plants or cement factories.

Renewable Energy Integration

With South Africa’s growing investment in hybrid renewable-mining projects, MP-GC cables are also used to link high-voltage distribution nodes to energy storage systems.

Installation Recommendations

Proper installation is crucial to ensure cable longevity:

Bending Radius: Maintain at least 12 × OD during installation to prevent insulation cracking.

Support and Routing: Use rollers and guides to prevent jacket abrasion in tunnels or conduits.

Grounding: Always connect grounding and ground-check conductors according to electrical codes for maximum safety.

Direct Burial: If buried, ensure the trench is clear of sharp rocks; use protective sand bedding if necessary.

Spacing: Avoid tightly grouping high-voltage cables in confined ducts to minimize heat build-up.

Frequently Asked Questions (FAQ)

1. What is the main advantage of MP-GC cables compared to standard power cables?

They are specifically engineered for mining with grounding and monitoring conductors, rugged jackets, and high dielectric insulation for 15kV distribution.

2. Can MP-GC cables be used outdoors in South Africa’s climate?

Yes. The CPE jacket resists UV, oil, and weathering, making it suitable for open-pit mines and harsh surface environments.

3. How do MP-GC cables improve safety in mines?

The ground-check conductor provides real-time monitoring of the grounding system, ensuring faults are detected before accidents occur.

4. Are these cables compliant with South African regulations?

Yes. While based on ICEA and CSA standards, MP-GC cables are acceptable in South Africa if they meet NRCS and SANS 1520-1 guidelines for mining cables.

5. What is the expected lifespan of an MP-GC cable?

With correct installation and maintenance, service life often exceeds 10–15 years in underground mines.

The Type MP-GC Three-Conductor Mine Power Feeder Cable with CPE Jacket (15kV) represents a cornerstone of modern mining and heavy industry infrastructure. Its robust construction, compliance with international standards, and adaptability across underground and surface applications make it indispensable to South Africa’s industrial backbone.

In an era where South African mines face pressures from energy constraints, safety regulations, and efficiency demands, choosing the right power distribution cable is not just a technical decision—it’s a strategic one. By investing in MP-GC cables, operators can ensure safer, more reliable, and future-ready mining operations.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430