Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type MP-GC Three-Conductor Mine Power Feeder Cable, CPE Jacket, 5kV ICEA S-75-381

Type MP-GC 3C1 AWG 5kV Three-Conductor Mine Power Feeder Cable with CPE Jacket- a robust solution for mining power needs

Type MP-GC Three-Conductor Mine Power Feeder Cable, CPE Jacket, 5kV ICEA S-75-381

Applications | These cables are designed for connections between units of mine distribution systems, suitable forinstalled in duct, conduit or open air and for direct burial in wet and dry locations. |

Standards | ICEA S-75-381/NEMA WC 58 |

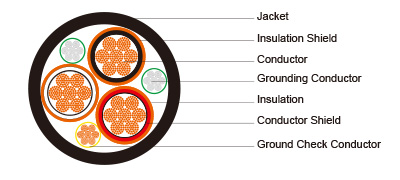

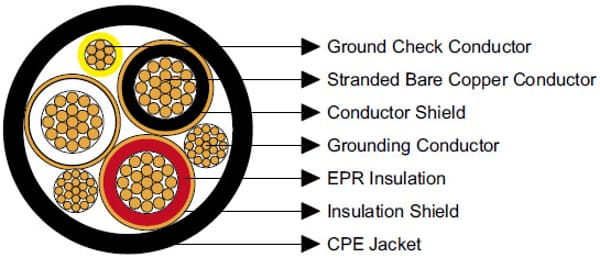

Construction  | |

Conductors | Stranded annealed bare copper conductor. |

Conductor Shield | Conducting layer. |

Insulation | Ethylene Propylene Rubber (EPR). |

Insulation Shield | Conducting layer + copper tape. |

Ground Check Conductor | Copper conductor with a yellow polypropylene insulation. |

Grounding Conductor | Tinned copper conductor. |

Jacket | Chlorinated Polyethylene(CPE), black. |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 12×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Ground CheckConductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×6 | 7 | 10 | 8 | 0.09 | 2.3 | 0.11 | 2.8 | 1.30 | 33.0 | 1060 | 1577 | 93 |

3×4 | 7 | 8 | 8 | 0.09 | 2.3 | 0.11 | 2.8 | 1.41 | 35.8 | 1441 | 2144 | 122 |

3×2 | 7 | 6 | 8 | 0.09 | 2.3 | 0.11 | 2.8 | 1.47 | 37.3 | 1827 | 2718 | 159 |

3×1 | 19 | 5 | 8 | 0.09 | 2.3 | 0.11 | 2.8 | 1.54 | 39.1 | 2168 | 3226 | 184 |

3×1/0 | 19 | 4 | 8 | 0.09 | 2.3 | 0.11 | 2.8 | 1.63 | 41.4 | 2602 | 3871 | 211 |

3×2/0 | 19 | 3 | 8 | 0.09 | 2.3 | 0.11 | 2.8 | 1.72 | 43.7 | 3010 | 4478 | 243 |

3×3/0 | 19 | 2 | 8 | 0.09 | 2.3 | 0.14 | 3.6 | 1.89 | 48.0 | 3265 | 4859 | 279 |

3×4/0 | 19 | 1 | 8 | 0.09 | 2.3 | 0.14 | 3.6 | 2.01 | 51.0 | 4190 | 6234 | 321 |

3×250 | 37 | 1/0 | 8 | 0.09 | 2.3 | 0.14 | 3.6 | 2.10 | 53.3 | 4825 | 7179 | 355 |

3×350 | 37 | 2/0 | 8 | 0.09 | 2.3 | 0.14 | 3.6 | 2.31 | 58.7 | 6062 | 9019 | 435 |

3×500 | 37 | 4/0 | 8 | 0.09 | 2.3 | 0.14 | 3.6 | 2.59 | 65.8 | 8427 | 12538 | 536 |

Benefits of the Type MP-GC Cable

The Type MP-GC cable offers several advantages that make it a preferred choice for mining applications:

Three-Phase Power Efficiency: The cable supports a three-phase power supply, which is essential for heavy machinery like drills, crushers, and conveyors. Three-phase systems provide a balanced power load, reducing energy losses and ensuring consistent performance, which translates to lower operational costs.

Durability of CPE Jacket: The CPE jacket is resistant to abrasion, chemicals, oils, and solvents, ensuring longevity in aggressive mining environments. Its flame-retardant properties enhance safety in high-risk settings.

High Tensile Strength: The cable’s robust construction allows it to withstand frequent movement and mechanical stress, making it ideal for mobile equipment in open-pit or underground mines.

Flexibility: Despite its rugged design, the cable remains flexible, enabling easy routing through confined spaces and around obstacles.

Safety Features: The ground check conductor and grounding conductor ensure continuous monitoring and effective grounding, reducing the risk of electrical faults and enhancing worker safety.

Customization Options: The cable can be tailored with alternative jacket materials (e.g., CSP, PCP, NBR, PVC) or a two-layer jacket with reinforcing fiber for enhanced durability, depending on environmental conditions.

Comparison with SHD-GC Cables

While the Type MP-GC cable excels in feeder applications, it’s worth comparing it to SHD-GC (Shielded, Heavy-Duty, Ground-Check) cables to understand their distinct roles:

Type MP-GC: Optimized for high-voltage feeder applications, delivering power to large machinery. Its high tensile strength makes it suitable for dynamic environments where cables endure mechanical stress.

SHD-GC: Designed for applications requiring additional shielding against electromagnetic interference (EMI), making it ideal for environments with sensitive equipment.

The choice between MP-GC and SHD-GC depends on the specific needs of the mining operation, such as the presence of EMI or the requirement for high tensile strength.

Installation and Maintenance Recommendations

Proper installation and maintenance are crucial to maximizing the performance and lifespan of the Type MP-GC cable. Here are some recommendations:

Installation

Bending Radius: Adhere to the minimum bending radius of 12 × overall diameter (18.48 inches for the 3C1 AWG configuration) to prevent damage to the insulation or conductors.

Environment Suitability: The cable is suitable for duct, conduit, open air, or direct burial in wet and dry locations. Ensure proper sealing in wet environments to prevent water ingress.

Routing: Avoid sharp edges or abrasive surfaces during installation to protect the CPE jacket. Use cable trays or supports in open-air installations to minimize stress.

Grounding: Properly connect the grounding and ground check conductors to the system to ensure safety and compliance with MSHA standards.

Maintenance

Regular Inspections: Periodically inspect the cable for signs of wear, abrasion, or chemical damage, especially in high-traffic areas or near chemical exposure.

Cleaning: Remove dust, dirt, or chemical residues from the jacket to maintain its protective properties.

Testing: Conduct regular electrical testing to verify insulation integrity and ground continuity, particularly in harsh mining environments.

Repairs: Replace damaged sections promptly to prevent electrical faults. Use compatible materials for repairs to maintain MSHA compliance.

Usage Scenarios in South Africa’s Mining Industry

South Africa’s mining sector, a cornerstone of the country’s economy, relies heavily on robust electrical infrastructure. The Type MP-GC cable is ideally suited for various applications in this context:

Underground Gold and Platinum Mining: In the Witwatersrand Basin, where gold mining remains a key industry, the Type MP-GC cable powers underground drills and ventilation systems. Its CPE jacket withstands the humid, abrasive conditions of deep mines, ensuring uninterrupted power supply.

Open-Pit Coal Mines: In Mpumalanga, open-pit coal mines use the cable to power massive draglines and conveyors. Its high tensile strength and flexibility make it ideal for mobile equipment that requires frequent repositioning.

Diamond Mining in Kimberley: The cable’s flame-retardant properties are critical in diamond mines, where dust and flammable materials pose fire risks. Its ability to handle high voltages supports heavy machinery used in ore extraction.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430