Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type MP-GC Three-Conductor Mine Power Feeder Cable, CPE Jacket, 8kV to ICEA S-75-381

Type MP-GC Three-Conductor Mine Power Feeder Cable: Designed to meet ICEA S-75-381 standards and support safe, reliable mining operations in South Africa

Type MP-GC Three-Conductor Mine Power Feeder Cable, CPE Sheath, 8kV to ICEA S-75-381

Applications | These cables are designed for connections between units of mine distribution systems, suitable forinstalled in duct, conduit or open air and for direct burial in wet and dry locations. |

Standards | ICEA S-75-381/NEMA WC 58 |

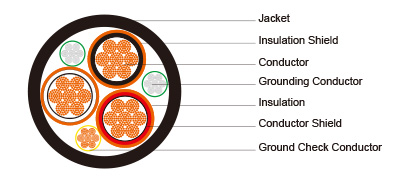

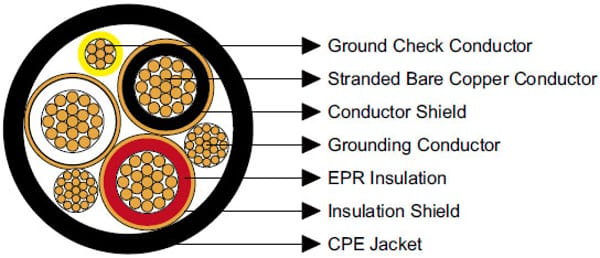

Construction  | |

Conductors | Stranded annealed bare copper conductor. |

Conductor Shield | Conducting layer. |

Insulation | Ethylene Propylene Rubber (EPR). |

Insulation Shield | Conducting layer + copper tape. |

Ground Check Conductor | Copper conductor with a yellow polypropylene insulation. |

Grounding Conductor | Tinned copper conductor. |

Jacket | Chlorinated Polyethylene(CPE), black. |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 12×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Ground Check Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×6 | 7 | 10 | 8 | 0.115 | 2.9 | 0.11 | 2.8 | 1.41 | 35.8 | 1175 | 1749 | 93 |

3×4 | 7 | 8 | 8 | 0.115 | 2.9 | 0.11 | 2.8 | 1.52 | 38.6 | 1608 | 2392 | 122 |

3×2 | 7 | 6 | 8 | 0.115 | 2.9 | 0.11 | 2.8 | 1.58 | 40.1 | 1919 | 2855 | 159 |

3×1 | 19 | 5 | 8 | 0.115 | 2.9 | 0.11 | 2.8 | 1.66 | 42.2 | 2507 | 3730 | 184 |

3×1/0 | 19 | 4 | 8 | 0.115 | 2.9 | 0.11 | 2.8 | 1.74 | 44.2 | 2660 | 3958 | 211 |

3×2/0 | 19 | 3 | 8 | 0.115 | 2.9 | 0.14 | 3.6 | 1.90 | 48.3 | 3257 | 4846 | 243 |

3×3/0 | 19 | 2 | 8 | 0.115 | 2.9 | 0.14 | 3.6 | 2.00 | 50.8 | 3432 | 5107 | 279 |

3×4/0 | 19 | 1 | 8 | 0.115 | 2.9 | 0.14 | 3.6 | 2.12 | 53.8 | 4382 | 6520 | 321 |

3×250 | 37 | 1/0 | 8 | 0.115 | 2.9 | 0.14 | 3.6 | 2.22 | 56.4 | 4965 | 7387 | 355 |

3×350 | 37 | 2/0 | 8 | 0.115 | 2.9 | 0.14 | 3.6 | 2.43 | 61.7 | 6484 | 9647 | 435 |

3×500 | 37 | 4/0 | 8 | 0.115 | 2.9 | 0.14 | 3.6 | 2.70 | 68.6 | 8857 | 13178 | 536 |

Applications of Type MP-GC Cables

MP-GC cables are used as mine power feeder cables in various heavy-duty applications. Their versatility supports installations in ducts, conduits, open air, and direct burial under both wet and dry conditions. Key applications include:

Underground Mine Power Distribution: Supplying power between substations, switchgear, and heavy machinery in deep-level gold and platinum mines in South Africa.

Open-Pit Mining Operations: Powering draglines, drills, and shovels that demand stable high-current transmission.

Processing Plants: Providing reliable energy for conveyor belts, crushers, and ventilation systems.

Direct Burial in Rugged Terrain: Suitable for wet and corrosive environments, such as coal mines in Mpumalanga.

Benefits of Type MP-GC Cables

High Safety Standards: Compliance with ICEA S-75-381 ensures performance reliability under stringent mining safety requirements.

Mechanical Durability: With abrasion- and crush-resistant jackets, MP-GC cables withstand harsh physical abuse typical in underground haulage tunnels.

Thermal Stability: EPR insulation ensures long service life at high operating temperatures.

Flexibility: Stranded copper conductors and flexible insulation make handling, installation, and routing easier in confined spaces.

Environmental Resistance: CPE sheathing resists oils, chemicals, and flames, extending service life.

Continuous Ground Monitoring: The ground check conductor enhances safety by allowing real-time monitoring of grounding integrity.

Frequently Asked Questions (FAQ)

1. What does MP-GC stand for?

It means Mine Power – Ground Check, indicating the cable is designed for mine power distribution with an additional ground monitoring conductor.

2. Can MP-GC cables be used outdoors?

Yes, they are suitable for open-air installations and direct burial, with resistance to moisture, UV, and chemicals.

3. Are MP-GC cables flame retardant?

Yes, the CPE jacket provides flame retardancy. Other jacket materials can be customized.

4. How are these cables different from standard industrial cables?

MP-GC cables have extra ground check conductors, tougher jackets, and higher flexibility, tailored for mining safety and reliability.

5. What is the expected service life?

With proper installation and maintenance, MP-GC cables can last 10–15 years in harsh mining environments.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430