Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type MP-GC Three-Conductor Mine Power Feeder Cable, PVC Jacket, 5kV ICEA S-75-381

Understanding Type MP-GC Three-Conductor Mine Power Feeder Cable with PVC Jacket 5kV in South Africa

Type MP-GC Three-Conductor Mine Power Feeder Cable, PVC Jacket, 5kV ICEA S-75-381

Applications | These cables are designed for connections between units of mine distribution systems, suitable fordirect burial in wet and dry locations. |

Standards | ICEA S-75-381/NEMA WC 58 |

Construction  | |

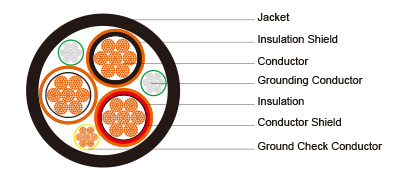

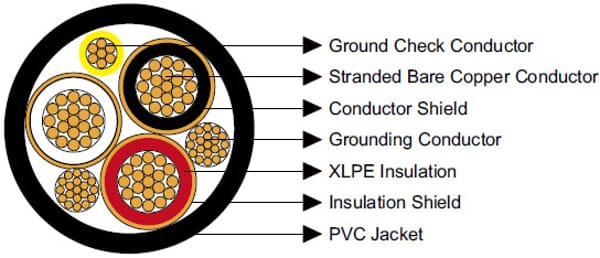

Conductors | Stranded annealed bare copper conductor. |

Conductor Shield | Conducting layer. |

Insulation | Cross-Linked Polyethylene (XLPE). |

Insulation Shield | Conducting layer + copper tape. |

Ground Check Conductor | Copper conductor with a yellow polypropylene insulation. |

Grounding Conductor | Tinned copper conductor. |

Jacket | Polyvinyl Chloride (PVC), black. |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 12×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Ground Check Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×4 | 7 | 8 | 8 | 0.09 | 2.3 | 0.11 | 2.8 | 1.41 | 35.8 | 1224 | 1821 | 122 |

3×2 | 7 | 6 | 8 | 0.09 | 2.3 | 0.11 | 2.8 | 1.47 | 37.3 | 1653 | 2459 | 159 |

3×1 | 19 | 5 | 8 | 0.09 | 2.3 | 0.11 | 2.8 | 1.54 | 39.1 | 1950 | 2901 | 184 |

3×1/0 | 19 | 4 | 8 | 0.09 | 2.3 | 0.11 | 2.8 | 1.63 | 41.4 | 2200 | 3273 | 211 |

3×2/0 | 19 | 3 | 8 | 0.09 | 2.3 | 0.11 | 2.8 | 1.72 | 43.7 | 2721 | 4048 | 243 |

3×3/0 | 19 | 2 | 8 | 0.09 | 2.3 | 0.14 | 3.6 | 1.89 | 48.0 | 3170 | 4720 | 279 |

3×4/0 | 19 | 1 | 8 | 0.09 | 2.3 | 0.14 | 3.6 | 2.01 | 51.0 | 3845 | 5721 | 321 |

3×250 | 37 | 1/0 | 8 | 0.09 | 2.3 | 0.14 | 3.6 | 2.10 | 53.3 | 4321 | 6429 | 355 |

3×350 | 37 | 2/0 | 8 | 0.09 | 2.3 | 0.14 | 3.6 | 2.31 | 58.7 | 5652 | 8409 | 435 |

3×500 | 37 | 4/0 | 8 | 0.09 | 2.3 | 0.14 | 3.6 | 2.59 | 65.8 | 7721 | 11487 | 536 |

Benefits of MP-GC Mine Power Feeder Cable

1. Electrical Reliability

High-quality stranded copper conductors and XLPE insulation provide low electrical losses and stable operation under fluctuating loads.

2. Safety

Grounding and ground-check conductors enhance monitoring, fault detection, and overall system safety—critical in South African mines where electrical accidents can have severe consequences.

3. Durability

With PVC or optional heavy-duty jackets, the cable resists abrasion, moisture, and chemical damage. The option of a reinforced double jacket is particularly valuable in deep-level gold and platinum mines where mechanical stress is extreme.

4. Flexibility of Installation

The wide range of conductor sizes allows operators to match cable specifications to power demands, reducing both cost and energy waste.

5. Compliance with International Standards

ICEA, NEMA, ASTM, and CSA compliance ensures global credibility and compatibility with multinational mining equipment standards.

Application Scenarios

Type MP-GC cables are versatile and well-suited for medium-voltage mine power distribution systems. Applications include:

Primary Feeder Lines: Connecting underground substations and distribution panels.

Mobile and Stationary Equipment: Supplying draglines, shovels, crushers, pumps, and conveyors.

Direct Burial Installations: Effective in both wet and dry soil conditions, reducing the need for extensive protective conduits.

South African Mines:

Gold Mines (Witwatersrand): Long feeder runs to deep shafts demand high ampacity cables.

Platinum Mines (Bushveld Complex): High mechanical stress environments benefit from reinforced jacket options.

Coal Mines (Mpumalanga): Exposure to wet and corrosive conditions makes PVC and CSP jacket options valuable.

The Type MP-GC Three-Conductor Mine Power Feeder Cable, PVC Jacket, 5kV is a proven solution for reliable, safe, and efficient power distribution in demanding mining environments. With XLPE insulation, grounding systems, and flexible jacket options, it is engineered to handle the harshest underground conditions.

In South Africa—where the mining industry faces pressures of safety compliance, rising energy costs, and operational efficiency—these cables are vital infrastructure. Real-world applications in gold, platinum, and coal mines illustrate their effectiveness in reducing downtime, improving safety, and lowering long-term costs.

By adopting MP-GC cables, mining companies can meet not only current demands but also future challenges, supporting sustainable growth and safer working conditions in one of the world’s most resource-rich regions.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430