Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type MP-GC Three-Conductor Mine Power Feeder Cable, PVC Jacket, 8kV ICEA S-75-381

Comprehensive Guide to Type MP-GC Three-Conductor Mine Power Feeder Cable with PVC Jacket 8kV ICEA S-75-381 for South African Mining and Heavy Industry Applications

Type MP-GC Three-Conductor Mine Power Feeder Cable, PVC Jacket, 8kV ICEA S-75-381

Applications | These cables are designed for connections between units of mine distribution systems, suitable forinstalled in duct, conduit or open air and for direct burial in wet and dry locations. |

Standards | ICEA S-75-381/NEMA WC 58 |

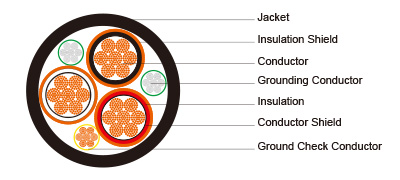

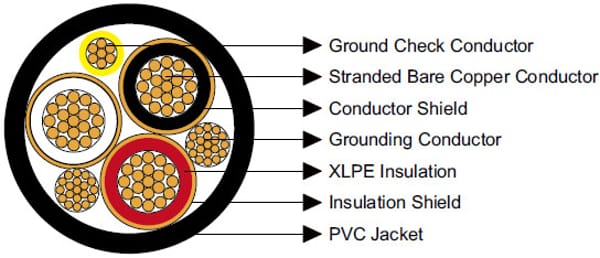

Construction  | |

Conductors | Stranded annealed bare copper conductor. |

Conductor Shield | Conducting layer. |

Insulation | Cross-Linked Polyethylene (XLPE). |

Insulation Shield | Conducting layer + copper tape. |

Ground Check Conductor | Copper conductor with a yellow polypropylene insulation. |

Grounding Conductor | Tinned copper conductor. |

Jacket | Polyvinyl Chloride (PVC), black. |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 12×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Ground Check Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×4 | 7 | 8 | 8 | 0.115 | 2.9 | 0.11 | 2.8 | 1.52 | 38.6 | 1366 | 2032 | 122 |

3×2 | 7 | 6 | 8 | 0.115 | 2.9 | 0.11 | 2.8 | 1.58 | 40.1 | 1727 | 2569 | 159 |

3×1 | 19 | 5 | 8 | 0.115 | 2.9 | 0.11 | 2.8 | 1.66 | 42.2 | 2174 | 3234 | 184 |

3×1/0 | 19 | 4 | 8 | 0.115 | 2.9 | 0.11 | 2.8 | 1.74 | 44.2 | 2656 | 3952 | 211 |

3×2/0 | 19 | 3 | 8 | 0.115 | 2.9 | 0.14 | 3.6 | 1.90 | 48.3 | 2895 | 4307 | 243 |

3×3/0 | 19 | 2 | 8 | 0.115 | 2.9 | 0.14 | 3.6 | 2.00 | 50.8 | 3320 | 4950 | 279 |

3×4/0 | 19 | 1 | 8 | 0.115 | 2.9 | 0.14 | 3.6 | 2.12 | 53.8 | 3983 | 5926 | 321 |

3×250 | 37 | 1/0 | 8 | 0.115 | 2.9 | 0.14 | 3.6 | 2.22 | 56.4 | 4484 | 6671 | 355 |

3×350 | 37 | 2/0 | 8 | 0.115 | 2.9 | 0.14 | 3.6 | 2.43 | 61.7 | 5827 | 8669 | 435 |

3×500 | 37 | 4/0 | 8 | 0.115 | 2.9 | 0.14 | 3.6 | 2.70 | 68.6 | 7893 | 11743 | 536 |

Benefits of Type MP-GC Mine Feeder Cable

High Electrical Reliability

Low resistance copper conductors and XLPE insulation maintain consistent voltage stability, reducing downtime.

Safety in Harsh Environments

Grounding and ground check conductors improve fault detection and reduce electrocution risks.

Mechanical Strength

Optional double-layer jackets with fiber reinforcement protect against crushing and abrasion in deep mines.

Versatility

Suitable for duct, conduit, open-air installations, and direct burial in both wet and dry locations.

Compliance and Certification

Meets ICEA, NEMA, ASTM, and CSA standards, ensuring international safety and quality benchmarks.

Cost-Effectiveness

Longer service life reduces maintenance costs, essential for South African mines aiming to optimize operational expenditure.

Application Scenarios

The Type MP-GC cable is indispensable in modern mining and heavy industry:

Underground Mining – Power feeders for drilling machines, ventilation fans, and underground substations.

Surface Mining – Distribution systems for crushers, conveyors, and pumping stations.

Heavy Industry – Steelworks, smelters, and chemical plants requiring reliable medium-voltage distribution.

Infrastructure Projects – Direct burial in wet conditions, such as dam construction sites or tunnels.

Installation and Maintenance Recommendations

Installation Guidelines:

Maintain bending radius ≥ 12 × OD.

Use proper pulling grips and rollers to prevent jacket damage.

Avoid sharp edges in conduits to protect the PVC jacket.

Install in compliance with local mining regulations (SANS 1520-1 for South Africa).

Maintenance Best Practices:

Perform periodic insulation resistance testing.

Monitor the ground check conductor for continuity.

Inspect jacket integrity for signs of abrasion, oil damage, or cracking.

Replace cables showing excessive mechanical wear.

Frequently Asked Questions (FAQ)

1. What does MP-GC stand for?

MP-GC stands for Mine Power – Ground Check. It indicates the cable’s suitability for mine power distribution with integrated grounding and monitoring conductors.

2. Can these cables be used in wet conditions?

Yes. Type MP-GC cables are designed for both wet and dry burial applications, making them ideal for underground mines prone to water ingress.

3. What is the difference between MP-GC and SHD-GC cables?

MP-GC is optimized for power feeder applications, while SHD-GC (Shielded, Ground Check) is often used in trailing or portable applications requiring greater flexibility.

4. Do these cables meet South African standards?

Yes. While they are designed to ICEA and NEMA standards, they also comply with SANS 1520-1 requirements when imported or locally certified for South African use.

5. How long is the service life of MP-GC cables?

With proper installation and maintenance, service life can exceed 10–15 years, depending on mechanical stress and environmental exposure.

The Type MP-GC Three-Conductor Mine Power Feeder Cable with PVC Jacket (8kV ICEA S-75-381) represents a critical solution for the power distribution challenges in South African mining and heavy industries. Its superior construction, compliance with international standards, and adaptability to diverse installation environments make it a cornerstone of modern mine safety and efficiency.

For South Africa, where mining is both an economic backbone and a high-risk industry, reliable power feeder cables like Type MP-GC are not just technical components—they are enablers of sustainable growth, safety, and competitiveness in global markets.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430