Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type SHD-CGC Three-Conductor Round Portable Power Cable 2kV

The Feichun Type SHD-CGC Advanced Shielded Power Cable for Harsh Industrial and Mining Applications in South Africa

Type SHD-CGC Three-Conductor Round Portable Power Cable 2kV

Applications

These heavy duty cables are designed for applications such as longwall shearers, continuous miners, loaders, drills, conveyors, pumps, and other mobile equipment requiring grounding conductors, where a ground check conductor, and metallic shielding are required.

Standards

ICEA S-75-381/NEMA WC 58

ASTM B 172

ASTM B 33

CAN/CSA C22.2 No. 96

Construction

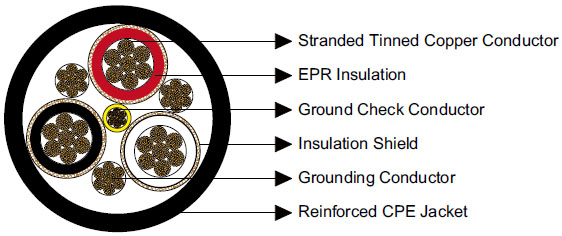

-17.jpg) |

Conductors | Stranded annealed tinned copper conductor. |

|---|---|

Insulation | Ethylene Propylene Rubber (EPR). |

Insulation Shield | Tinned copper/textile braid. |

Ground Check Conductor | Tinned copper with a yellow insulation, located in the center of the cable. |

Grounding Conductor | Tinned copper conductor. |

Jacket | Reinforced extra-heavy-duty Chlorinated Polyethylene (CPE), black. |

Options

Other jacket materials such as CSP/PCP/NBR/PVC are available upon request.

Two-layer jacket with reinforcing fibre between the two layers can be offered as an option.

Mechanical and Thermal Properties

Minimum Bending Radius | 6×OD |

|---|---|

Maximum Conductor Operating Temperature | +90℃ |

Dimensions and Weight

Construction | No. of Strands | Grounding Conductor Size | Ground Check Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter Height×Width | Nominal Weight | Ampacity | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of cores × AWG/kcmil | - | AWG/kcmil | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×2/0 | 342 | 5 | 16 | 0.08 | 2.0 | 0.205 | 5.2 | 2.09 | 53.1 | 3400 | 5059 | 243 |

3×3/0 | 418 | 4 | 16 | 0.08 | 2.0 | 0.205 | 5.2 | 2.21 | 56.1 | 3934 | 5853 | 279 |

3×4/0 | 532 | 3 | 16 | 0.08 | 2.0 | 0.220 | 5.6 | 2.36 | 59.9 | 4860 | 7231 | 321 |

3×350 | 888 | 1 | 16 | 0.95 | 2.4 | 0.250 | 6.3 | 2.81 | 71.4 | 7400 | 11010 | 435 |

Understanding Cable Types: What Makes SHD-CGC Stand Out?

Power cables come in various forms, from basic unshielded types used in residential settings to specialized armored and shielded variants for industrial use. In mining, where equipment like continuous miners, loaders, drills, conveyors, and pumps operates in confined, dusty, and vibration-heavy spaces, standard cables simply won't suffice. The SHD-CGC type falls under shielded heavy-duty (SHD) cables, specifically the "CGC" denoting its ground-check and grounding conductor features.

Unlike basic power cables, which might only have insulation and a jacket, the SHD-CGC incorporates advanced shielding to combat EMI—a common issue in high-voltage circuits where electromagnetic noise can disrupt signals and cause equipment malfunctions. This shielding typically involves a flexible copper/textile braid over a non-conducting tape underlayer, providing a barrier against interference while maintaining flexibility. The "portable" aspect means it's designed for trailing applications, where cables are frequently moved or flexed without breaking.

Comparing it to other types:

Type SHD-GC: Similar but lacks the comprehensive shielding; better for general grounding but less EMI-resistant.

Type W: Unshielded, suitable for lighter duties but vulnerable in EMI-heavy zones.

Armored Cables: Often used in fixed installations with steel armor for mechanical protection, but less flexible than SHD-CGC for mobile equipment.

The Feichun variant elevates this with ethylene propylene rubber (EPR) insulation, chlorinated polyethylene (CPE) jackets, and an extensible ground-check system. This makes it compliant with standards like ICEA S-75-381, ASTM B172, and CAN/CSA C22.2 No. 96, ensuring it's MSHA-approved for mining use. In South Africa, where regulatory bodies like the Department of Mineral Resources and Energy emphasize safety amid rising accident rates, such compliance is non-negotiable.

Benefits: Why Choose SHD-CGC for Industrial Demands?

The advantages of the Feichun SHD-CGC extend beyond specs into tangible operational gains. First, enhanced safety: The ground-check system and shielding prevent shock hazards and ensure continuous monitoring, reducing risks in high-EMI environments. In mines, where electrical faults can lead to fires or explosions, this is lifesaving.

Durability is another pillar. The CPE jacket and stranded conductors resist flex fatigue, extending lifespan in trailing applications. This translates to lower replacement costs—vital in South Africa, where substandard imported cables flood the market, posing threats to industries. Environmental resistance handles the continent's harsh climates, from dusty shafts to humid tunnels.

Performance efficiency: Minimal EMI disruption means smoother equipment operation, boosting productivity. For electrified mining fleets—a growing trend—the cable supports higher ampacities without overheating.

Finally, cost savings: Though premium, its longevity and reduced downtime offer ROI. Compliance with ICEA and MSHA standards avoids regulatory fines, while custom lengths and packaging (on non-returnable reels with +/-5% tolerance) streamline procurement.

Usage Scenarios: From Underground Mines to Heavy Industry

The SHD-CGC shines in applications requiring mobility and protection. In underground mining, it's used as trailing cables for longwall shearers, continuous miners, and loaders, providing power, grounding, and EMI shielding. For pumps and conveyors, its flexibility allows easy routing in tight spaces.

In high-EMI settings like power distribution systems, it protects against noise from nearby machinery. Fail-safe ground monitoring is essential for critical systems, ensuring immediate fault detection.

Beyond mining, it's apt for heavy industries like construction or oil rigs, but in South Africa, mining dominates. With the industry's shift to automation and digitalization, SHD-CGC cables integrate with smart sensors for real-time monitoring.

Installation and Maintenance Recommendations: Ensuring Longevity

Proper installation is key to maximizing SHD-CGC performance. Avoid excessive pulling tension (use pulling grips) and respect the 6×OD bending radius to preserve shield integrity. Route cables with adequate spacing to prevent overheating, and secure them against vibration.

For maintenance: Inspect regularly for cuts, abrasions, or jacket degradation. Test ground-check continuity quarterly, and monitor ampacity to avoid overloads. In wet environments, check for moisture ingress. Professional training is advised, especially in South Africa's regulated mines.

Store on reels in dry areas, and for custom setups, consult Feichun support.

A Cable for Tomorrow's Challenges

The Feichun Type SHD-CGC shielded power cable embodies innovation in cable technology, offering unmatched safety, durability, and efficiency for South Africa's mining and heavy industries. As the sector navigates 2025 trends like electrification and safety enhancements amid energy woes and theft, this cable provides a reliable solution. By investing in such advanced tech, operators not only comply with standards but also protect lives and boost productivity. For those in the field, it's time to upgrade—contact Feichun for tailored insights and embrace a safer future.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430