Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type SHD-CGC Three-Conductor Round Portable Power Cable 5kV ICEA S-75-381

Type SHD-CGC Three-Conductor Round Portable Power Cable 5kV-A Robust Solution for Mining and Heavy Industry in South Africa

Type SHD-CGC Three-Conductor Round Portable Power Cable 5kV

Applications

These heavy duty cables are designed for applications such as longwall shearers, continuous miners, loaders, drills, conveyors, pumps, and other mobile equipment requiring grounding conductors, where a ground check conductor, and metallic shielding are required.

Standards

ICEA S-75-381/NEMA WC 58

ASTM B 172

ASTM B 33

CAN/CSA C22.2 No. 96

Construction

-18.jpg) |

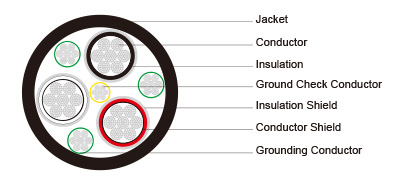

Conductors | Stranded annealed tinned copper conductor. |

|---|---|

Conductor Shield | Conducting layer. |

Insulation | Ethylene Propylene Rubber (EPR). |

Insulation Shield | Tinned copper/textile braid. |

Ground Check Conductor | Tinned copper with a yellow insulation, located in the center of the cable. |

Grounding Conductor | Tinned copper conductor. |

Jacket | Reinforced extra-heavy-duty Chlorinated Polyethylene (CPE), black. |

Options

Other jacket materials such as CSP/PCP/NBR/PVC/TPU are available upon request.

Two-layer jacket with reinforcing fibre between the two layers can be offered as an option.

Mechanical and Thermal Properties

Minimum Bending Radius | 6×OD |

|---|---|

Maximum Conductor Operating Temperature | +90℃ |

Dimensions and Weight

Construction | No. of Strands | Grounding Conductor Size | Ground Check Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter Height×Width | Nominal Weight | Ampacity | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of cores × AWG/kcmil | - | AWG/kcmil | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×2/0 | 323 | 5 | 16 | 0.11 | 2.8 | 0.220 | 5.6 | 2.20 | 55.9 | 3716 | 5529 | 243 |

3×3/0 | 418 | 4 | 16 | 0.11 | 2.8 | 0.235 | 6.0 | 2.36 | 59.9 | 4130 | 6145 | 279 |

3×4/0 | 532 | 3 | 16 | 0.11 | 2.8 | 0.235 | 6.0 | 2.50 | 63.5 | 5190 | 7722 | 321 |

3×350 | 888 | 1 | 16 | 0.12 | 3.0 | 0.265 | 6.7 | 2.95 | 74.9 | 7571 | 11264 | 435 |

Type SHD-CGC Three-Conductor Round Portable Power Cable 5kV compliant with standards such as ICEA S-75-381 and NEMA WC 58, is engineered for applications involving mobile equipment such as longwall shearers, continuous miners, loaders, drills, conveyors, and pumps. Its robust construction provides not only power transmission but also essential grounding and shielding features, making it indispensable in scenarios where safety and reliability are paramount. As South African mines grapple with infrastructure limitations and the push toward energy transition—including the adoption of renewable sources like solar hybrid microgrids—these portable power cables play a crucial role in bridging the gap between unreliable national grids and on-site power needs.

What is a Type SHD-CGC Cable?

At its core, the Type SHD-CGC (Shielded Heavy Duty - Continuous Ground Check) cable is a specialized portable power cable tailored for high-voltage applications up to 5kV. Unlike standard power cables used in fixed installations, this three-conductor round variant is built for mobility and durability in harsh industrial settings. The "SHD" designation indicates its heavy-duty shielding, which protects against electromagnetic interference and mechanical stress, while "CGC" refers to the inclusion of a ground check conductor, ensuring continuous monitoring of grounding integrity—a critical safety feature in environments prone to electrical faults.

These cables fall under the broader category of trailing cables, commonly used in mining and heavy industry where equipment must move freely without compromising power supply. In South Africa, where deep-level mining operations dominate sectors like gold, platinum, and coal, such cables are essential for powering equipment in confined, dust-laden tunnels. The round configuration enhances flexibility, allowing the cable to bend and twist without kinking, which is vital for dynamic operations like those involving continuous miners that advance through rock faces.

To appreciate its design, consider the layered construction: It starts with stranded annealed tinned copper conductors for superior conductivity and corrosion resistance. A conducting layer serves as the conductor shield, followed by Ethylene Propylene Rubber (EPR) insulation, known for its excellent thermal and electrical properties. An insulation shield of tinned copper/textile braid adds further protection, while a central ground check conductor—tinned copper with yellow insulation—monitors grounding. Additional grounding conductors ensure redundancy, and the whole assembly is encased in a reinforced extra-heavy-duty Chlorinated Polyethylene (CPE) jacket, black in color for visibility and durability.

Options like alternative jacket materials (e.g., CSP, PCP, NBR, or PVC) or a two-layer jacket with reinforcing fibers cater to specific needs, such as enhanced abrasion resistance in abrasive mining environments. This adaptability makes the Type SHD-CGC a versatile choice, aligning with global standards like ASTM B 172, ASTM B 33, and CAN/CSA C22.2 No. 96, ensuring compatibility across international operations.

Benefits of Type SHD-CGC Cables

The advantages of deploying Type SHD-CGC cables in heavy industry are multifaceted. Foremost is enhanced safety: The integrated ground check and shielding minimize electrical hazards, reducing the likelihood of shocks or fires in volatile environments. In South Africa's mines, where fatalities from machinery incidents remain a concern (54 reported in 2023), such features are lifesavers.

Durability is another key benefit. The CPE jacket withstands abrasion, chemicals, and extreme temperatures, extending service life and cutting replacement costs. This is particularly valuable amid rising operational expenses, where energy alone can account for up to 35% of mining budgets. Flexibility ensures minimal downtime during equipment repositioning, boosting productivity in fast-paced operations like longwall mining.

From an efficiency standpoint, high ampacity ratings (up to 435A for larger sizes) support power-hungry machinery, while low weight relative to performance eases handling. Environmentally, the cable's compliance with standards promotes sustainable practices, and options for eco-friendly jackets align with the sector's shift toward green mining.

Usage Scenarios and Case Studies

The Type SHD-CGC cable shines in mobile heavy industry applications, particularly South Africa's mining sector, where equipment like continuous miners and loaders demand uninterrupted power. In underground coal mines, it powers shearers advancing through seams, its portability allowing seamless extension as operations progress.

Amid 2025's energy trends, with mines investing in hybrid microgrids to combat grid unreliability, these cables connect generators or solar arrays to equipment, ensuring continuity during load shedding. For instance, in platinum mines around Rustenburg, where power surges have caused equipment failures, the cable's shielding protects sensitive electronics.

A notable use case draws from recent developments in critical mineral extraction, such as lithium and cobalt projects in the Northern Cape. Here, drills and pumps rely on 5kV cables for high-ampacity needs, supporting the sector's projected 12% GDP boost by 2050.

Consider a hypothetical yet realistic case study inspired by current trends: At a major gold mine in Gauteng, frequent Eskom outages halted continuous miners, costing thousands in lost production daily. By integrating Type SHD-CGC cables with diesel generators and emerging solar hybrids, the mine achieved 95% uptime. The ground check feature prevented a potential fault during a surge, averting downtime. This mirrors broader efforts, where $3.8 billion in renewable investments are transforming power reliability.

Another scenario involves surface mining trends, where excavators and conveyors use these cables for temporary setups amid infrastructure upgrades called for at events like Mining Indaba. In heavy industry beyond mining, such as construction in industrial hubs, the cable supports pumps during infrastructure projects, addressing political and logistical challenges.

As South Africa's mining and heavy industry sectors evolve in 2025, the Type SHD-CGC Three-Conductor Round Portable Power Cable 5kV stands as a beacon of reliability and innovation. By addressing energy crises through robust design and versatile applications, it empowers operations to thrive amid challenges. Embracing such technologies ensures a safer, more efficient future—proving that in the world of heavy industry, the right cable can indeed power progress.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430