Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type SHD-GC Three-Conductor Portable Power Cable, TPU Jacket 15kV ICEA S-75-381

Type SHD-GC Three-Conductor Portable Power Cable with TPU Jacket 15kV for Mining and Heavy Industry in South Africa

Type SHD-GC Three-Conductor Portable Power Cable, TPU Jacket 15kV ICEA S-75-381

Applications | These heavy duty cables are designed for applications such as longwall shearers, continuous miners and mobile equipment such as shovels, dredges and drills. |

Standards | ICEA S-75-381/NEMA WC 58 |

Construction  | |

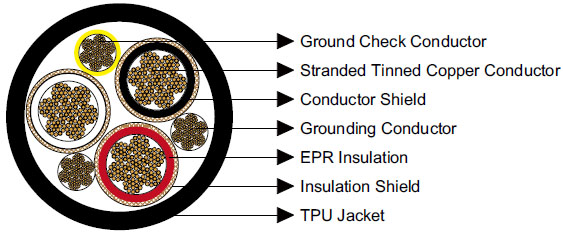

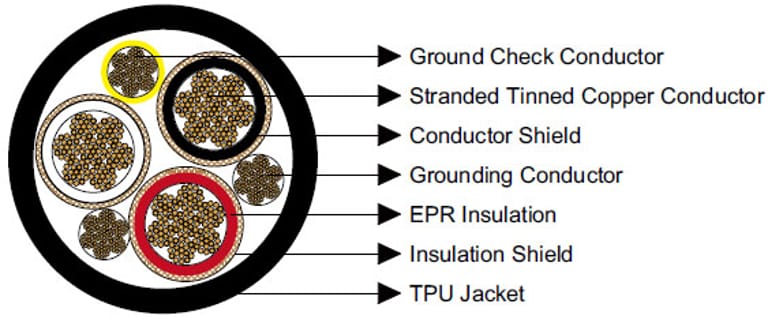

Conductors | Stranded annealed tinned copper conductor. |

Conductor Shield | Semi-conducting layer. |

Insulation | Ethylene Propylene Rubber (EPR). |

Insulation Shield | Conducting tape + Tinned copper/textile braid. |

Ground Check Conductor | Tinned copper with a yellow polypropylene insulation. |

Grounding Conductor | Tinned copper conductor. |

Jacket | Reinforced extra-heavy-duty Chlorinated Polyethylene(CPE), black. |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Ground Check Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×4 | 259 | 8 | 8 | 0.150 | 3.8 | 0.205 | 5.2 | 1.94 | 49.3 | 2308 | 3594 | 122 |

3×2 | 259 | 6 | 8 | 0.150 | 3.8 | 0.220 | 5.6 | 2.12 | 53.8 | 2920 | 4554 | 159 |

3×1 | 329 | 5 | 8 | 0.150 | 3.8 | 0.220 | 5.6 | 2.21 | 56.1 | 3292 | 5104 | 184 |

3×1/0 | 259 | 4 | 8 | 0.150 | 3.8 | 0.220 | 5.6 | 2.32 | 58.9 | 3675 | 5700 | 211 |

3×2/0 | 329 | 3 | 8 | 0.150 | 3.8 | 0.235 | 6.0 | 2.46 | 62.5 | 4304 | 6593 | 243 |

3×3/0 | 413 | 2 | 8 | 0.150 | 3.8 | 0.250 | 6.4 | 2.62 | 66.5 | 5200 | 7738 | 279 |

3×4/0 | 532 | 1 | 8 | 0.150 | 3.8 | 0.250 | 6.4 | 2.75 | 69.8 | 5840 | 8713 | 321 |

3×250 | 608 | 1/0 | 6 | 0.150 | 3.8 | 0.250 | 6.4 | 2.89 | 73.4 | 6774 | 9948 | 355 |

3×300 | 741 | 1/0 | 6 | 0.150 | 3.8 | 0.265 | 6.7 | 3.04 | 77.2 | 7423 | 11384 | 398 |

3×350 | 888 | 2/0 | 6 | 0.150 | 3.8 | 0.280 | 7.1 | 3.21 | 81.3 | 8543 | 12739 | 435 |

3×500 | 1221 | 4/0 | 6 | 0.150 | 3.8 | 0.295 | 7.5 | 3.56 | 90.4 | 11260 | 16757 | 536 |

In South Africa, mining remains the backbone of the economy. From deep-level gold mines in Gauteng to sprawling platinum operations in the North West and Limpopo, reliable electricity is indispensable. Heavy mobile equipment such as continuous miners, longwall shearers, shovels, and dredges depend on robust, flexible power cables that can endure mechanical stress, harsh environmental conditions, and continuous movement.

One of the most widely adopted solutions is the Type SHD-GC three-conductor portable power cable with TPU jacket 15kV, manufactured to meet ICEA S-75-381 and NEMA WC 58 standards. This cable is designed to deliver both electrical performance and mechanical resilience, making it a critical technology in modern mining and industrial environments.

Cable Overview: Type SHD-GC Portable Power Cable

What is SHD-GC?

SHD: Shielded, Heavy-Duty

GC: Ground Check

The cable is a flexible, heavy-duty, shielded power cable designed for use in medium-voltage (up to 15 kV) applications, especially where equipment is mobile, continuously re-positioned, or exposed to mechanical stress. The ground check conductor is a safety feature that allows monitoring of the grounding system integrity, a crucial requirement in mining operations.

Standards and Compliance

ICEA S-75-381 / NEMA WC 58 – U.S. standard for portable and power cables.

ASTM B 172 / ASTM B 33 – Governs conductor quality and performance.

CAN/CSA C22.2 No. 96 – Canadian compliance for mining and portable cables.

These standards ensure that SHD-GC cables meet stringent safety, durability, and performance benchmarks.

Why Choose SHD-GC Cables?

Safety and Reliability

The ground check conductor enables real-time fault monitoring, preventing hazardous ground faults.

Shielded design reduces electromagnetic interference (EMI).

Mechanical Strength

Jackets reinforced with TPU or CPE withstand mechanical wear, cuts, and impact.

Electrical Performance

EPR insulation ensures stable dielectric strength across long runs.

Flexibility

Stranded copper conductors and rubber insulation allow repeated bending without cracking.

Environmental Resistance

Resistant to UV, ozone, oil, and chemicals common in mining environments.

Usage Scenarios in South Africa

South Africa’s mining and industrial environment creates unique demands:

Underground Gold Mines (Gauteng)

SHD-GC cables power continuous miners and longwall shearers where flexibility and safety are critical.

Open-Pit Platinum Mines (North West & Limpopo)

Used with draglines and shovels, where the cable must endure dragging, coiling, and extreme mechanical stress.

Coal Mining (Mpumalanga)

Powers shuttle cars and drills, providing safe, continuous energy in dust-filled, abrasive conditions.

Ports and Industrial Applications (Durban, Richards Bay)

Supplies power to dredging equipment and mobile cranes, ensuring operational reliability.

Frequently Asked Questions (FAQ)

Q1: What does SHD-GC stand for?

A: Shielded, Heavy-Duty, Ground Check. It refers to a mining-grade portable power cable with integrated safety features.

Q2: Can SHD-GC cables be used in open-pit and underground mines?

A: Yes, they are designed for both environments, depending on jacket type and voltage requirements.

Q3: Why is the ground check conductor important?

A: It continuously monitors grounding integrity, preventing dangerous faults in live mining environments.

Q4: What jacket material is best for South African mines?

A: TPU jackets are preferred for extreme abrasion resistance, while CPE offers excellent balance between durability and cost.

Q5: How long do SHD-GC cables typically last?

A: With proper installation and maintenance, service life can exceed 3–5 years, depending on mechanical stress and environment.

The Type SHD-GC three-conductor portable power cable with TPU jacket 15kV is a cornerstone technology for South Africa’s mining and heavy industries. Its combination of mechanical durability, electrical reliability, and safety features makes it the preferred choice for powering critical mobile equipment in some of the harshest environments on earth.

As mining operations modernize and electrify, the demand for high-performance, flexible, and safe cables will only grow. For South Africa, investing in SHD-GC cables is not just about technical efficiency—it is about ensuring worker safety, reducing downtime, and supporting sustainable industrial growth.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430