Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type SHD-GC Three-Conductor Round Portable Power Cable, CPE Jacket 15kV ICEA S-75-381

Type SHD-GC Three-Conductor Round Portable Power Cable: Designed for Longwall Shearers, Continuous Miners and Mobile Equipment

Type SHD-GC Three-Conductor Round Portable Power Cable, CPE Jacket 15kV ICEA S-75-381

Applications | These heavy duty cables are designed for applications such as longwall shearers, continuous miners and mobile equipment such as shovels, dredges and drills. |

Standards | ICEA S-75-381/NEMA WC 58 |

Construction  | |

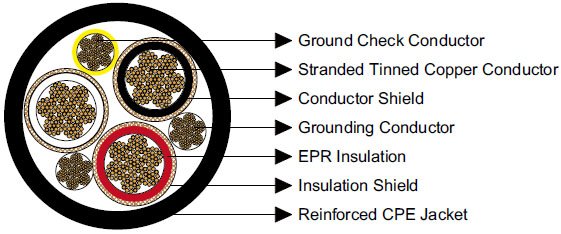

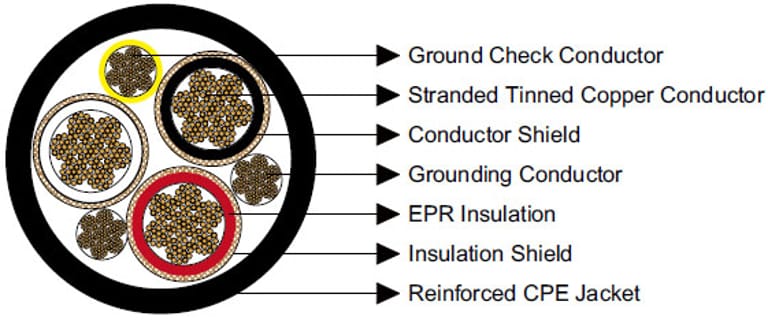

Conductors | Stranded annealed tinned copper conductor. |

Conductor Shield | Semi-conducting layer. |

Insulation | Ethylene Propylene Rubber (EPR). |

Insulation Shield | Conducting tape + Tinned copper/textile braid. |

Ground Check Conductor | Tinned copper with a yellow polypropylene insulation. |

Grounding Conductor | Tinned copper conductor. |

Jacket | Reinforced extra-heavy-duty Chlorinated Polyethylene (CPE), black. |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 8×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Ground Check Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×2 | 259 | 6 | 8 | 0.210 | 5.3 | 0.235 | 6.0 | 2.41 | 61.2 | 3572 | 5529 | 164 |

3×1 | 259 | 5 | 8 | 0.210 | 5.3 | 0.235 | 6.0 | 2.52 | 64.0 | 4060 | 6042 | 187 |

3×1/0 | 259 | 4 | 8 | 0.210 | 5.3 | 0.250 | 6.4 | 2.64 | 67.0 | 4495 | 6927 | 215 |

3×2/0 | 329 | 3 | 8 | 0.210 | 5.3 | 0.250 | 6.4 | 2.73 | 69.3 | 5010 | 7783 | 246 |

3×3/0 | 413 | 2 | 8 | 0.210 | 5.3 | 0.265 | 6.7 | 2.90 | 73.7 | 5995 | 8922 | 283 |

3×4/0 | 532 | 1 | 8 | 0.210 | 5.3 | 0.265 | 6.7 | 3.05 | 77.5 | 6860 | 10209 | 325 |

What is a Type SHD-GC Cable?

Type SHD-GC (Shielded, Ground, Ground Check) cables are a class of heavy-duty portable power cables designed specifically for high-power mobile equipment in mining, tunnelling, and construction environments. The “GC” designation indicates that the cable includes a ground check conductor, a critical safety feature that continuously monitors the grounding integrity of the system.

These cables are built to meet rigorous standards such as:

ICEA S-75-381 / NEMA WC 58 – governing portable and mining cables.

ASTM B172 and ASTM B33 – defining conductor properties.

CAN/CSA C22.2 No. 96 – Canadian standard for portable mining cables.

Their key applications include:

Longwall shearers – critical for underground coal mining.

Continuous miners – equipment used to cut and gather material.

Shovels, dredges, and drills – mobile machinery in open-pit mining.

Other heavy-duty mobile industrial equipment requiring flexible high-voltage connections.

Benefits of SHD-GC Cables

Safety – Ground and ground-check conductors continuously monitor grounding, reducing the risk of electrocution and arc faults.

Durability – Designed with reinforced jackets to withstand abrasion, impact, and exposure to oils and chemicals.

Flexibility – EPR insulation and stranded copper conductors allow repeated bending and movement.

High Voltage Capability – Rated up to 15kV for large mining machines.

Compliance with Standards – Meets ICEA, ASTM, and CSA standards, ensuring international compatibility.

Cost Efficiency – Reduced downtime thanks to reliability lowers overall operational costs.

Installation Recommendations

Correct installation is critical for maximizing the lifespan and safety of SHD-GC cables. Key practices include:

Bending Radius: Maintain at least 8× OD to prevent insulation cracking.

Strain Relief: Use proper clamping and reels to prevent excessive mechanical stress.

Protection: Avoid sharp edges, dragging over rough ground, or chemical spills during handling.

Connector Quality: Use appropriate mining-grade couplers to ensure secure connections.

Testing: Conduct dielectric and ground-check continuity tests before energization.

Maintenance Guidelines

Routine inspections are vital in the mining sector, where cables often face mechanical abuse. Recommendations include:

Visual Inspections – Check for jacket cuts, abrasions, and bulges.

Electrical Testing – Insulation resistance and ground-check functionality should be verified regularly.

Cleaning – Remove mud, oil, and conductive dust deposits that could compromise safety.

Re-termination – Damaged ends can often be repaired with proper splicing kits.

Rotation – In high-wear areas, periodically rotate cables to distribute stress.

Applications in South Africa

1. Underground Coal Mines in Mpumalanga

SHD-GC cables power continuous miners and shuttle cars, where their flexibility is essential for frequent repositioning.

2. Platinum Mines in Rustenburg

Mobile drilling and cutting equipment rely on these cables, which must endure constant flexing and abrasive rock surfaces.

3. Open-Pit Gold Mining in Gauteng

Dragline shovels and drills require long cable runs with high voltage capacity. SHD-GC cables provide stable power despite constant movement and exposure to dust and chemicals.

4. Renewable Energy and Heavy Industry

South Africa’s growing renewable energy projects and steel manufacturing plants also employ SHD-GC cables for mobile power distribution in temporary and high-demand scenarios.

Frequently Asked Questions (FAQ)

1. What does “SHD-GC” stand for?

SHD = Shielded, Heavy Duty; GC = Ground Check.

2. What voltage ratings are available?

Typically rated up to 15kV, suitable for heavy-duty mining and industrial equipment.

3. Why is the ground check conductor important?

It ensures continuous monitoring of grounding integrity, preventing dangerous faults.

4. Can SHD-GC cables be repaired if damaged?

Yes, with proper mining cable splicing kits, though replacement is recommended for major damage.

5. Are SHD-GC cables suitable for surface as well as underground use?

Yes, their reinforced jackets and flexibility make them versatile for both environments.

6. What are common jacket options besides CPE?

CSP, PCP, NBR, and PVC can be chosen based on chemical or environmental conditions.

7. How often should SHD-GC cables be inspected?

At least weekly in high-use mining environments, with full electrical testing monthly.

In South Africa’s mining and heavy industry, where electrical reliability equates to safety and productivity, the Type SHD-GC three-conductor round portable power cable is indispensable. Its robust construction, compliance with international standards, and built-in safety mechanisms make it the backbone of mobile power distribution.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430