Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type SHD-GC Three-Conductor Round Portable Power Cable, CPE Jacket 25kV ICEA S-75-381

Type SHD-GC Three-Conductor Round Portable Power Cable, CPE Jacket 25kV: Balancing High Electrical Performance, Mechanical Durability, and Compliancing with International Standards

Type SHD-GC Three-Conductor Round Portable Power Cable, CPE Jacket 25kV ICEA S-75-381

Applications | These heavy duty cables are designed for applications such as longwall shearers, continuous miners and mobile equipment such as shovels, dredges and drills. |

Standards | ICEA S-75-381/NEMA WC 58 |

Construction  | |

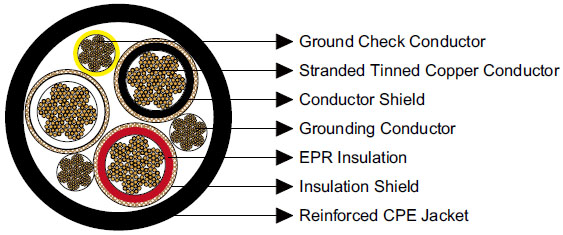

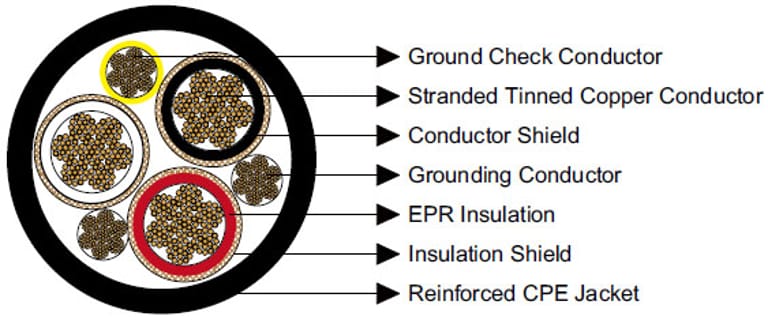

Conductors | Stranded annealed tinned copper conductor. |

Conductor Shield | Conducting layer. |

Insulation | Ethylene Propylene Rubber (EPR). |

Insulation Shield | Conducting tape + Tinned copper/textile braid. |

Ground Check Conductor | Tinned copper with a yellow polypropylene insulation. |

Grounding Conductor | Tinned copper conductor. |

Jacket | Reinforced extra-heavy-duty Chlorinated Polyethylene (CPE), black. |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 8×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Ground Check Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×1 | 259 | 5 | 8 | 0.260 | 6.6 | 0.265 | 6.7 | 2.95 | 74.9 | 5290 | 7872 | 191 |

3×1/0 | 259 | 4 | 8 | 0.260 | 6.6 | 0.265 | 6.7 | 3.05 | 77.5 | 5800 | 8631 | 218 |

3×2/0 | 329 | 3 | 8 | 0.260 | 6.6 | 0.280 | 7.1 | 3.20 | 81.3 | 6515 | 9695 | 249 |

3×3/0 | 413 | 2 | 8 | 0.260 | 6.6 | 0.280 | 7.1 | 3.33 | 84.6 | 7215 | 10737 | 286 |

3×4/0 | 532 | 1 | 8 | 0.260 | 6.6 | 0.295 | 7.5 | 3.50 | 88.9 | 8250 | 12277 | 327 |

In modern mining and heavy industry, safe and reliable power distribution is a cornerstone of productivity. South Africa, home to some of the world’s largest mining operations, requires advanced cable technology to power equipment such as longwall shearers, continuous miners, shovels, dredges, and drilling rigs. One of the most trusted solutions is the Type SHD-GC three-conductor round portable power cable with CPE jacket, rated up to 25 kV.

Engineered to meet demanding conditions, this cable balances high electrical performance, mechanical durability, and compliance with international standards such as ICEA S-75-381, ASTM B 172, ASTM B 33, and CAN/CSA C22.2 No. 96. Its robust construction and safety features make it a preferred choice for operators in regions where heavy-duty, flexible, and safe cables are essential.

Key Benefits of Type SHD-GC Cable

Durability in Harsh Environments

Designed for mining operations where mechanical stress, moisture, abrasion, and chemical exposure are common.

Enhanced Safety

Ground check conductor provides continuous monitoring to prevent accidents.

Flame-retardant and oil-resistant jacket reduces fire risks.

Flexibility and Mobility

Suitable for portable applications, including reeling, trailing, and festooning systems.

Extended Service Life

Resistant to UV, chemicals, and extreme temperatures, reducing downtime and replacement costs.

Compliance with International Standards

Meets ICEA, ASTM, CSA, and NEMA requirements, ensuring reliability and performance.

Applications in South Africa’s Mining and Heavy Industry

South Africa’s economy is deeply rooted in mining, from gold and platinum to coal and manganese. Equipment in these operations demands cables capable of handling high voltage, heavy loads, and extreme conditions.

Common Applications

Underground Mining: Longwall shearers and continuous miners.

Open-Cast Mining: Shovels, drills, draglines, and conveyor systems.

Industrial Operations: Dredging, tunneling, and heavy construction equipment.

Ports and Logistics: Powering cranes and bulk material handling systems.

Installation and Maintenance Recommendations

To maximize the life of Type SHD-GC cables, proper installation and routine inspection are critical.

Installation Best Practices

Maintain minimum bending radius of 8×OD.

Avoid sharp edges or over-tight cable clamps.

Use reels or festoon systems for moving equipment.

Ensure proper grounding before energizing.

Maintenance Guidelines

Conduct regular visual inspections for abrasion, cuts, or jacket swelling.

Test ground check conductor continuity.

Monitor insulation resistance to detect early failures.

Store cables in a cool, dry environment when not in use.

Frequently Asked Questions (FAQ)

1. What does SHD-GC stand for?

SHD = Shielded, High-Voltage, Portable Power Cable.

GC = Ground Check.

2. What is the voltage rating of Type SHD-GC cable?

Typically available up to 25 kV, depending on design.

3. Why is the ground check conductor important?

It continuously monitors grounding integrity, preventing dangerous faults in portable mining equipment.

4. Can Type SHD-GC be used in wet conditions?

Yes, its CPE jacket provides moisture and chemical resistance.

5. How does it compare with Type G-GC cable?

Type G-GC is rated up to 2 kV and used for lighter applications, while SHD-GC is a high-voltage cable designed for heavy-duty mining.

6. Does it comply with South African standards?

While primarily designed to ICEA/ASTM, many suppliers adapt SHD-GC cables to SANS 1520-1 and NRCS requirements for local compliance.

The Type SHD-GC three-conductor round portable power cable is a proven solution for South Africa’s mining and heavy industrial operations. Its robust construction, superior insulation, ground check monitoring, and compliance with international standards make it an essential choice for high-voltage applications.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430